Information injection-pump assembly

BOSCH

9 400 613 891

9400613891

ZEXEL

101402-4110

1014024110

ISUZU

8943879120

8943879120

Rating:

Service parts 101402-4110 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-103-2

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 891

9400613891

ZEXEL

101402-4110

1014024110

ISUZU

8943879120

8943879120

Zexel num

Bosch num

Firm num

Name

9 400 613 891

8943879120 ISUZU

INJECTION-PUMP ASSEMBLY

4BD1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4BD1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.9

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

63.2

62.1

64.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.9+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6.6

9.4

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

86

86

96

Fixing the lever

*

Rack limit

*

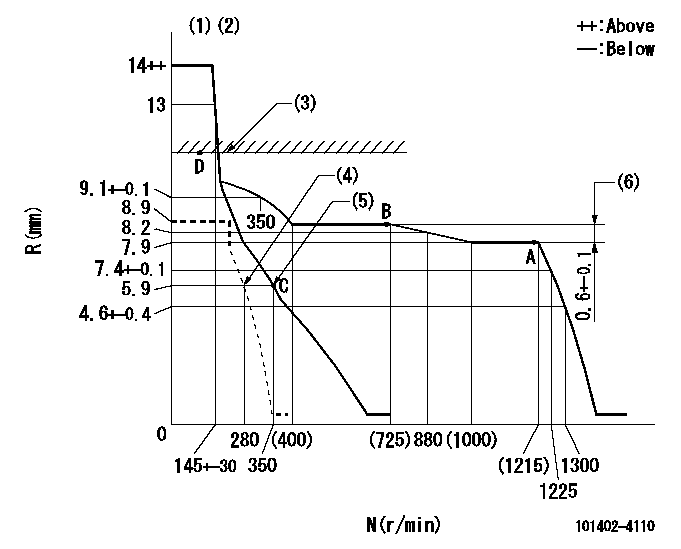

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=9 N1=1200r/min N2=700r/min

----------

----------

K=9 N1=1200r/min N2=700r/min

----------

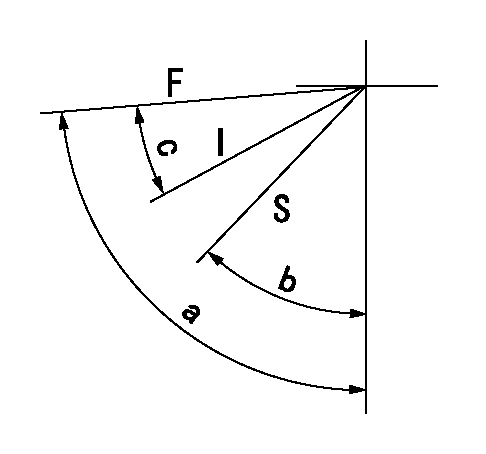

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=81deg+-5deg b=40deg+-3deg c=22deg+-5deg

----------

----------

a=81deg+-5deg b=40deg+-3deg c=22deg+-5deg

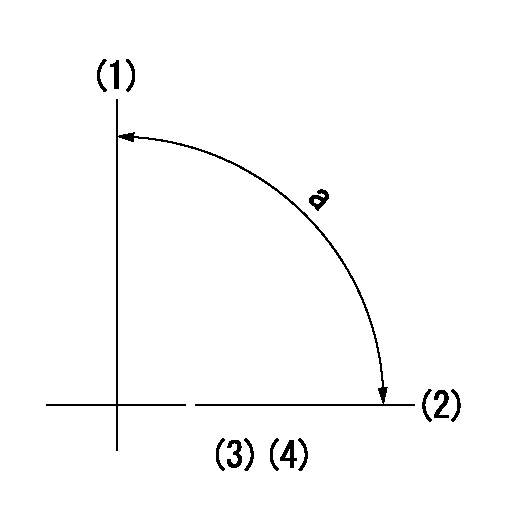

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(90deg)

----------

aa=18deg

----------

a=(90deg)

Information:

start by:a) remove turbocharger1. Put identification marks on the two housings and the cartridge assembly for use at assembly. 2. Remove two clamps (3) and make a separation of compressor housing (1) and turbine housing (2) from the cartridge assembly.

When the nut is loosened, do not put a side force on the shaft.

3. Put cartridge assembly (4) in position on tooling (A). Remove the nut from the shaft. 4. Use a press to push the shaft assembly out of the cartridge assembly. Remove compressor wheel (5). 5. Remove seal ring (8) and shroud (7) from shaft assembly (6). 6. Remove snap ring (9) with tool (B). 7. Use two screwdrivers to remove insert (10) from the cartridge housing. 8. Remove O-ring seal (12) from the insert.9. Remove sleeve (11) from the insert. Remove the seal ring from the sleeve. 10. Remove deflector (13) from the housing. 11. Remove bearing (14) from the cartridge housing. 12. Remove sleeve (15) and bearing (16) from the cartridge housing. 13. Remove ring (17). 14. Use tool (C) to remove snap ring (19), bearing (18) and snap ring (20) from the cartridge housing. 15. Turn the cartridge housing over. Use tool (C) to remove snap ring (22), bearing (21) and snap ring (23) from the housing.Assemble Turbocharger (Schwitzer 4MF)

1. Make sure all oil passages are open and clean. Put clean engine oil on all parts before assembly. 2. Use tool (A) to install snap ring (2), bearing (3) and snap ring (1) in the housing. Install the snap rings with the round side toward the bearing. 3. Turn the housing over. Use tool (A) to install snap ring (5), bearing (6) and snap ring (4). Install the snap rings with the round side toward the bearing. 4. Put ring (7) in position in the housing. 5. Put bearing (8) in position. Make an alignment of the holes in the bearing with the dowels in the housing. Grooved side of the bearing must be up.6. Put sleeve (9) in position in the housing. 7. Put ring (10) in position on top of the bearing. 8. Install deflector (11) as shown. 9. Put seal ring (13) in position on sleeve (12). Install the sleeve in insert (15).10. Put O-ring seal (14) in position on the insert. 11. Put insert assembly (16) in position in the housing. 12. Use tool (B) to install snap ring (17) in the housing. 13. Put shaft assembly (18) in position on tooling (C).14. Put 6V2055 High Vacuum Grease in the seal ring groove on the shaft assembly.15. Install seal ring (19) on shaft assembly (18). 16. Put shroud (20) in position on the shaft assembly.17. Put cartridge housing (22) and compressor wheel (21) in position on the shaft assembly.

Do not put a side force on the shaft when the nut is tightened.

18. Put a small amount of oil on the face of the compressor wheel that will be under the nut. Install the nut and tighten it to a torque

When the nut is loosened, do not put a side force on the shaft.

3. Put cartridge assembly (4) in position on tooling (A). Remove the nut from the shaft. 4. Use a press to push the shaft assembly out of the cartridge assembly. Remove compressor wheel (5). 5. Remove seal ring (8) and shroud (7) from shaft assembly (6). 6. Remove snap ring (9) with tool (B). 7. Use two screwdrivers to remove insert (10) from the cartridge housing. 8. Remove O-ring seal (12) from the insert.9. Remove sleeve (11) from the insert. Remove the seal ring from the sleeve. 10. Remove deflector (13) from the housing. 11. Remove bearing (14) from the cartridge housing. 12. Remove sleeve (15) and bearing (16) from the cartridge housing. 13. Remove ring (17). 14. Use tool (C) to remove snap ring (19), bearing (18) and snap ring (20) from the cartridge housing. 15. Turn the cartridge housing over. Use tool (C) to remove snap ring (22), bearing (21) and snap ring (23) from the housing.Assemble Turbocharger (Schwitzer 4MF)

1. Make sure all oil passages are open and clean. Put clean engine oil on all parts before assembly. 2. Use tool (A) to install snap ring (2), bearing (3) and snap ring (1) in the housing. Install the snap rings with the round side toward the bearing. 3. Turn the housing over. Use tool (A) to install snap ring (5), bearing (6) and snap ring (4). Install the snap rings with the round side toward the bearing. 4. Put ring (7) in position in the housing. 5. Put bearing (8) in position. Make an alignment of the holes in the bearing with the dowels in the housing. Grooved side of the bearing must be up.6. Put sleeve (9) in position in the housing. 7. Put ring (10) in position on top of the bearing. 8. Install deflector (11) as shown. 9. Put seal ring (13) in position on sleeve (12). Install the sleeve in insert (15).10. Put O-ring seal (14) in position on the insert. 11. Put insert assembly (16) in position in the housing. 12. Use tool (B) to install snap ring (17) in the housing. 13. Put shaft assembly (18) in position on tooling (C).14. Put 6V2055 High Vacuum Grease in the seal ring groove on the shaft assembly.15. Install seal ring (19) on shaft assembly (18). 16. Put shroud (20) in position on the shaft assembly.17. Put cartridge housing (22) and compressor wheel (21) in position on the shaft assembly.

Do not put a side force on the shaft when the nut is tightened.

18. Put a small amount of oil on the face of the compressor wheel that will be under the nut. Install the nut and tighten it to a torque