Information injection-pump assembly

BOSCH

9 400 613 428

9400613428

ZEXEL

101402-3452

1014023452

KOMATSU

6131721212

6131721212

Rating:

Service parts 101402-3452 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6-13112-310-0

12.

Open Pre:MPa(Kqf/cm2)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 428

9400613428

ZEXEL

101402-3452

1014023452

KOMATSU

6131721212

6131721212

Zexel num

Bosch num

Firm num

Name

101402-3452

9 400 613 428

6131721212 KOMATSU

INJECTION-PUMP ASSEMBLY

S4D105 K

S4D105 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

3.5

3.45

3.55

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

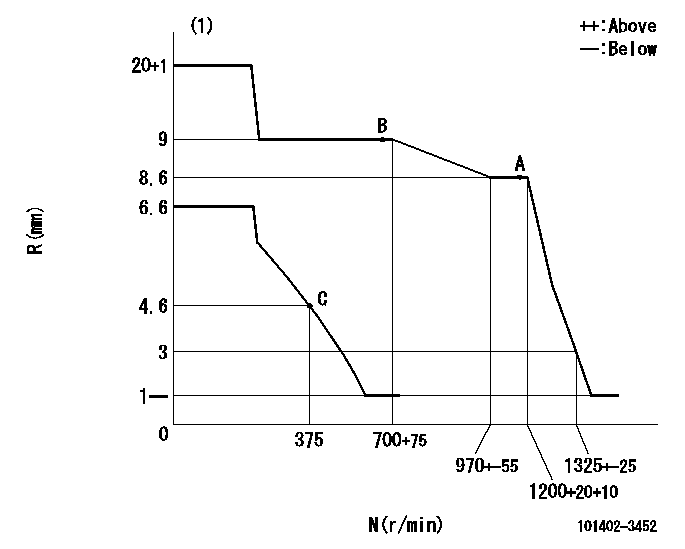

Injection quantity adjustment

Adjusting point

A

Rack position

8.6

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

85

83

87

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

83

83

88

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

4.6+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

10

8

12

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=15

----------

----------

K=15

----------

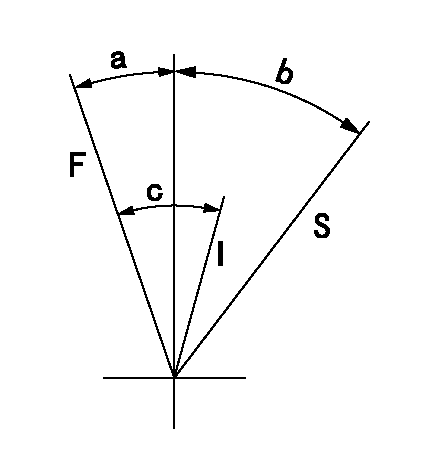

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=16deg+-5deg b=32deg+-3deg c=23deg+-5deg

----------

----------

a=16deg+-5deg b=32deg+-3deg c=23deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of center of spline's wide tooth at No 1 cylinder's beginning of injection (key position)

(3)B.T.D.C.: aa

(4)-

----------

aa=21deg

----------

a=(30deg)

----------

aa=21deg

----------

a=(30deg)

Information:

Important Safety Information

Illustration 1 g02139237Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools to perform these functions properly. Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. If a tool, a procedure, a work method, or operating technique that is not recommended by Caterpillar is used, ensure that it is safe for you and for other people to use. Ensure that the product will not be damaged or the product will not be made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result in injury or death.Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons.The hazards are identified by the safety alert symbol which is followed by a signal word such as danger, warning, or caution. The "" safety alert symbol is shown below.

Illustration 2 g00008666This safety alert symbol means:Pay attention!Become alert!Your safety is involved.The message that appears under the safety alert symbol explains the hazard.Operations that may cause product damage are identified by "" labels on the product and in this publication.Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. The safety information in this document and the safety information on the machine are not all inclusive. Determine that the tools, procedures, work methods, and operating techniques are safe. Determine that the operation, lubrication, maintenance, and repair procedures will not damage the machine. Also, you must determine that the operation, lubrication, maintenance, and repair procedures will not make the machine unsafe.The information, the specifications, and the illustrations that exist in this guideline are based on information which was available at the time of publication. The specifications, torques, pressures, measurements, adjustments, illustrations, and other items can change at any time. These changes can affect the service that is given to the product. Obtain the complete, most current information before you start any job. Caterpillar dealers can supply the most current information.Summary

The information included in this guideline should serve as an aid in fuel injection pump housing test procedure.Service Letters and Technical Information Bulletins

The most recent Service Letters and Technical Information Bulletins

Illustration 1 g02139237Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools to perform these functions properly. Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. If a tool, a procedure, a work method, or operating technique that is not recommended by Caterpillar is used, ensure that it is safe for you and for other people to use. Ensure that the product will not be damaged or the product will not be made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result in injury or death.Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons.The hazards are identified by the safety alert symbol which is followed by a signal word such as danger, warning, or caution. The "" safety alert symbol is shown below.

Illustration 2 g00008666This safety alert symbol means:Pay attention!Become alert!Your safety is involved.The message that appears under the safety alert symbol explains the hazard.Operations that may cause product damage are identified by "" labels on the product and in this publication.Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. The safety information in this document and the safety information on the machine are not all inclusive. Determine that the tools, procedures, work methods, and operating techniques are safe. Determine that the operation, lubrication, maintenance, and repair procedures will not damage the machine. Also, you must determine that the operation, lubrication, maintenance, and repair procedures will not make the machine unsafe.The information, the specifications, and the illustrations that exist in this guideline are based on information which was available at the time of publication. The specifications, torques, pressures, measurements, adjustments, illustrations, and other items can change at any time. These changes can affect the service that is given to the product. Obtain the complete, most current information before you start any job. Caterpillar dealers can supply the most current information.Summary

The information included in this guideline should serve as an aid in fuel injection pump housing test procedure.Service Letters and Technical Information Bulletins

The most recent Service Letters and Technical Information Bulletins

Have questions with 101402-3452?

Group cross 101402-3452 ZEXEL

Komatsu

101402-3452

9 400 613 428

6131721212

INJECTION-PUMP ASSEMBLY

S4D105

S4D105