Information injection-pump assembly

ZEXEL

101402-3440

1014023440

KOMATSU

6131721110

6131721110

Rating:

Service parts 101402-3440 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6131-12-3100

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Cross reference number

ZEXEL

101402-3440

1014023440

KOMATSU

6131721110

6131721110

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

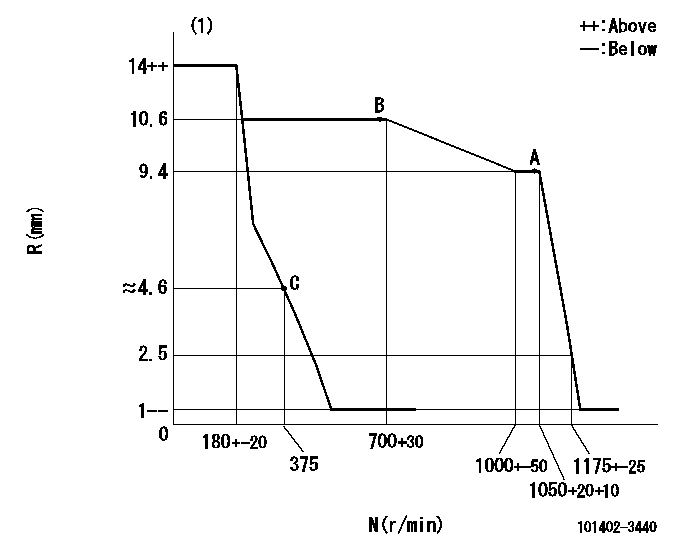

Injection quantity adjustment

Adjusting point

A

Rack position

9.4

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

73

71

75

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.6

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

80

80

84

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

4.6+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

10

8

12

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=10

----------

----------

K=10

----------

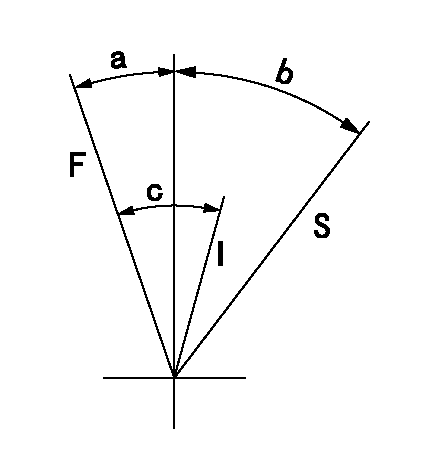

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=11deg+-5deg b=32deg+-3deg c=36deg+-3deg

----------

----------

a=11deg+-5deg b=32deg+-3deg c=36deg+-3deg

Timing setting

(1)Pump vertical direction

(2)Position of center of spline's wide tooth at No 1 cylinder's beginning of injection (key position)

(3)B.T.D.C.: aa

(4)-

----------

aa=21deg

----------

a=(30deg)

----------

aa=21deg

----------

a=(30deg)

Information:

These recommendations are subject to change without notice. Consult your local Cat dealer for the most up to date recommendations.

Diesel engines may burn a wide variety of fuels. These fuels are divided into two general groups. The two groups are called the preferred fuels and the permissible fuels.The preferred fuels provide maximum engine service life and performance. The preferred fuels are distillate fuels. These fuels are commonly called diesel fuel, furnace oil, gas oil, or kerosene. These fuels must meet the “Cat Specification for Distillate Diesel Fuel for Off-Highway Diesel Engines” found in this Special Publication, "Distillate Diesel Fuel" article.The permissible fuels are some crude oils, some blends of crude oil with distillate fuel, and some marine diesel fuel. These fuels are not suitable for use in all engine applications. The acceptability of these fuels for use is determined on a case by case basis. A complete fuel analysis is required. Consult your Cat dealer for further information. Biodiesel fuel is permissible for use in Cat engines. Follow all the recommendations and guidelines given in this Special Publication, "Biodiesel" article.Note: Except for some biodiesel, permissible fuels are not acceptable for use in on-highway applications.

Use of permissible fuels can result in higher maintenance costs and reduced engine service life.

Note: Use of fuels that do not meet at least the minimum performance recommendations and/or requirements may lead to lower compartment performance and/or compartment failure. Problems/failures that are caused by using fuels that do not meet the minimum recommended and/or required performance level are not Cat factory defects and therefore are NOT covered by the Cat warranty. The fuel supplier and customer are responsible.