Information injection-pump assembly

BOSCH

9 400 612 517

9400612517

ZEXEL

101402-2362

1014022362

HINO

220206102A

220206102a

Rating:

Service parts 101402-2362 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-3420A

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/21.6{220}

14.

NOZZLE

Cross reference number

BOSCH

9 400 612 517

9400612517

ZEXEL

101402-2362

1014022362

HINO

220206102A

220206102a

Zexel num

Bosch num

Firm num

Name

101402-2362

9 400 612 517

220206102A HINO

INJECTION-PUMP ASSEMBLY

W04D K 14BD INJECTION PUMP ASSY PE4AD PE

W04D K 14BD INJECTION PUMP ASSY PE4AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

83

81

85

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.5+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

11.5

10

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

11++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

90

100

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

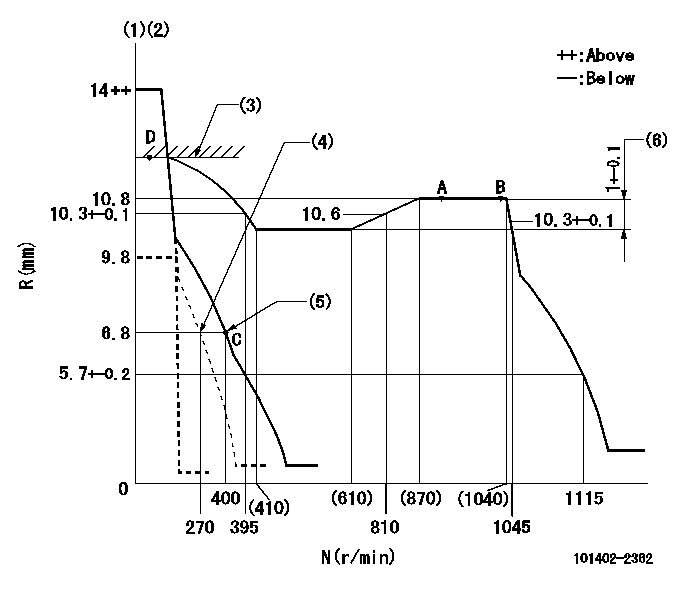

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=12 N1=900r/min N2=500r/min

----------

----------

K=12 N1=900r/min N2=500r/min

----------

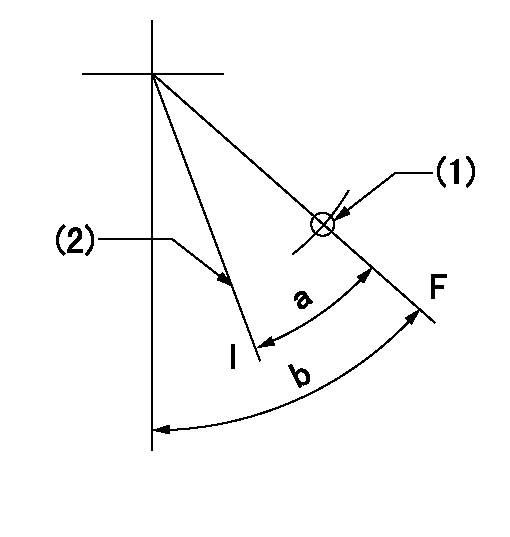

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=80mm

----------

a=26deg+-5deg b=52deg+-5deg

----------

aa=80mm

----------

a=26deg+-5deg b=52deg+-5deg

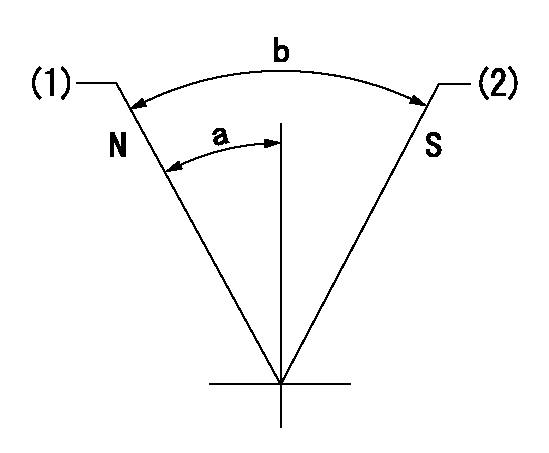

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Rack position aa or less, pump speed bb

----------

aa=6.3mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=6.3mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

PROBLEM

The existing fuel injectors can experience injector failures due to injector body cracking. If the existing injector fails it can result in complaints of high oil levels due to excessive fuel dilution.

AFFECTED PRODUCT

Model Identification Number

C27 A6X00101-00105

EGG00100

NAR00100-00119

T4Z00100, 200-227, 236

C32 NST00100-00108

SDK00101-00198

PMC27 N1B00100-00105, 107-118, 120-126, 128

PARTS NEEDED

Qty

Part Number Description

2 1R1808 FILTER-LUBE

12 8S9191 BOLT

12 3594060 INJECTOR GP-FUEL

1 BULK_OIL DEO (Refer to the OMM for Refill Capacities)

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 2% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

If excessive fuel dilution of engine oil is found reference the following to determine the cause of fuel dilution.

Refer to Special Instruction, REHS3007, "Determining the Cause of Fuel Dilution of Engine Oil"

Troubleshooting C27 and C32 Engines:

UENR0505 C27 Petroleum Generator Set Engines

UENR0504 C27 and C32 Industrial Engines

KENR9192 C27 Generator Set Engines

Once an injector(s) has been identified as having a cracked/leaking injector body, replace the failed injector(s). Inspect the remaining good injector serial numbers with Cat ET, (Injector Serial Numbers = Injector trim file name, (ie 6Cxxxxxxxxxx.trm)). If the remaining injector serial numbers fall within the serial number range below, replace at the same time. Refer to Image 1 for the serial number location on the top of the electronic unit injector.

Injector Serial Numbers

6C001793971D through 6C002198297C

8S-9191 Injector Hold Down Bolt must be replaced.

Refer to Disassembly and Assembly, KENR8167 for the removal, installation, and tightening procedures.

After the engine is reassembled, change the engine oil and filters.

Image1

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-3500 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

3501-6000 hrs,

25-48 mo 50.0% 50.0% 0.0% 0.0% 50.0% 50.0%

This is a 10.0-hour job

If there has been a previous repair, part age/hours will apply. Retain a copy of the previous repair invoice in the dealer's records for audit purposes, and specify repair date and machine hours in the "Additional Comments" section of the warranty claim.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101402-2362?

Group cross 101402-2362 ZEXEL

Hino

Hino

Hino

Hino

101402-2362

9 400 612 517

220206102A

INJECTION-PUMP ASSEMBLY

W04D

W04D