Information injection-pump assembly

BOSCH

9 400 613 869

9400613869

ZEXEL

101402-2352

1014022352

HINO

220206091B

220206091b

Rating:

Service parts 101402-2352 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 869

9400613869

ZEXEL

101402-2352

1014022352

HINO

220206091B

220206091b

Zexel num

Bosch num

Firm num

Name

101402-2352

9 400 613 869

220206091B HINO

INJECTION-PUMP ASSEMBLY

W04D-T K

W04D-T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

255

255

Overflow valve opening pressure

kgf/cm2

2.6

2.6

2.6

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

67.5

65.5

69.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.6+-0.5

Pump speed

r/min

485

485

485

Average injection quantity

mm3/st.

8.5

7

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

9.9++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

110

120

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1-0.3

Boost pressure

kPa

12.5

9.8

15.2

Boost pressure

mmHg

94

74

114

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(8.6)

Boost pressure

kPa

20

14.7

25.3

Boost pressure

mmHg

150

110

190

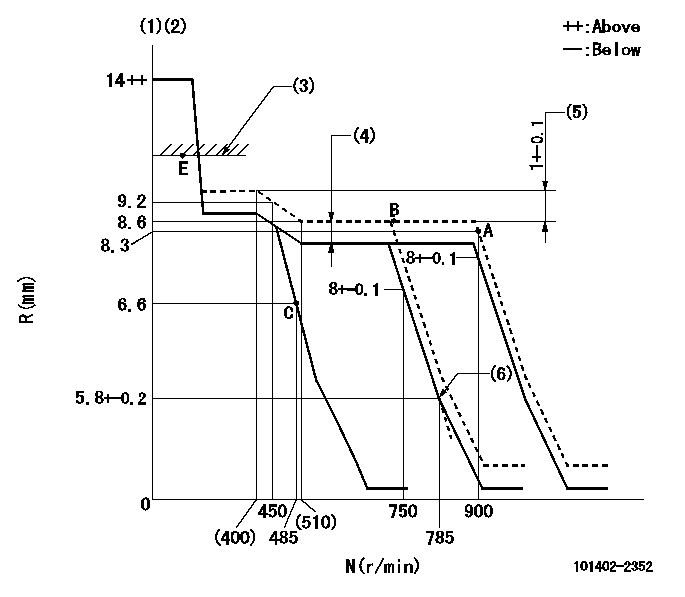

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

(5)Rack difference between N = N1 and N = N2

(6)Idle sub spring setting: L1.

----------

K=12 BCL=0.3+-0.1mm N1=750r/min N2=350r/min L1=5.8-0.5mm

----------

----------

K=12 BCL=0.3+-0.1mm N1=750r/min N2=350r/min L1=5.8-0.5mm

----------

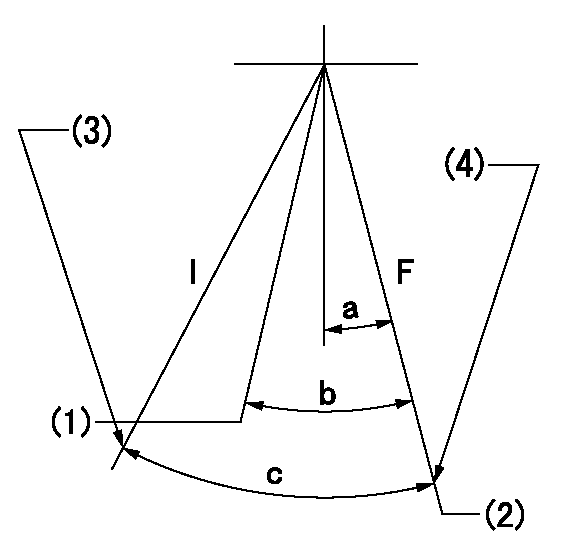

Speed control lever angle

F:Full speed

I:Idle

(1)When pump speed set at aa

(2)Set the pump speed at bb.

(3)Stopper bolt setting

(4)Stopper bolt setting

----------

aa=750r/min bb=900r/min

----------

a=16deg+-5deg b=6deg+-5deg c=2deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=16deg+-5deg b=6deg+-5deg c=2deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Introduction

The problem identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of faults codes with the DEF Pump, which can lead to an engine derate condition. Affected part numbers for the DEF pumps are:

473-2749 Diesel Exhaust Fluid Pump Gp

473-2750 Diesel Exhaust Fluid Pump Gp

466-8285 Diesel Exhaust Fluid Pump Gp

466-8286 Diesel Exhaust Fluid Pump GpThe codes can be:

Table 1

Event Codes

J1939 Code CDL Code Description

4334-16 E930 (2) Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2)

4334-18 E931 (2) Aftertreatment #1 SCR Dosing Re-agent Absolute Pressure : Low - moderate severity (2)

4374-5 E3118 (6) Aftertreatment #1 Diesel Exhaust Fluid Pump Motor Speed : Current Below Normal

5392-31 E1370 (2) Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime Caterpillar is investigating the root cause of these issues. To support the investigation, Caterpillar is requesting that the following steps are completed, documented, and recorded in SIMSi.Solution

Before starting any troubleshooting, download a Product Status Report (PSR) from the affected engine. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.Follow the appropriate troubleshooting steps for the displayed fault codes. Document the results of the troubleshooting tests in the relevant tables. Refer to Tables 2, 3, and 4.If Troubleshoot requests the Pump and Electronics Unit (PEU) to be replaced, conduct the following inspection before removal of the PEU.

Check the DEF for contamination, if the relevant troubleshooting procedure has not instructed you to do so. Refer to "System Operation Testing and Adjusting", Diesel Exhaust Fluid Quality - Test for the correct procedure.

Inspect the DEF tank cap, DEF header filter, DEF pump filter for any visible obstruction

Illustration 1 g06152768

(1) DEF line in

(2) DEF line out

(3) DEF line out let connection

(4) DEF line inlet connection

(5) Injector DEF line

Inspect and photograph both ends of the DEF fluid lines. If the ends of the lines are damaged or swollen, replace the DEF lines. Refer to "Disassembly and Assembly", Diesel Exhaust Fluid Lines - Remove and Install.At the end of the service take another PSR irrespective of outcome. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.If the troubleshooting steps have required a component to be changed, hold all replaced components for 30 days for a possible Parts Return Request (PRR). Make sure to include the closed work order paperwork.In every instance submit a SIMSi report, complete with TIB number M0079072, CPI number 359775 and submit through the CPI feedback tool within the SIMSi.

Detailed description of symptom experienced and under what conditions issue occurred

Product Status Report (PSR) before and after troubleshooting. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.

Completed Troubleshooting steps tables. Refer to Tables 2, 3, and 4.

Details of DEF tank cap, DEF header filter, DEF pump filter, visual inspection

Photos of DEF fluid lines

Details

The problem identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of faults codes with the DEF Pump, which can lead to an engine derate condition. Affected part numbers for the DEF pumps are:

473-2749 Diesel Exhaust Fluid Pump Gp

473-2750 Diesel Exhaust Fluid Pump Gp

466-8285 Diesel Exhaust Fluid Pump Gp

466-8286 Diesel Exhaust Fluid Pump GpThe codes can be:

Table 1

Event Codes

J1939 Code CDL Code Description

4334-16 E930 (2) Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2)

4334-18 E931 (2) Aftertreatment #1 SCR Dosing Re-agent Absolute Pressure : Low - moderate severity (2)

4374-5 E3118 (6) Aftertreatment #1 Diesel Exhaust Fluid Pump Motor Speed : Current Below Normal

5392-31 E1370 (2) Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime Caterpillar is investigating the root cause of these issues. To support the investigation, Caterpillar is requesting that the following steps are completed, documented, and recorded in SIMSi.Solution

Before starting any troubleshooting, download a Product Status Report (PSR) from the affected engine. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.Follow the appropriate troubleshooting steps for the displayed fault codes. Document the results of the troubleshooting tests in the relevant tables. Refer to Tables 2, 3, and 4.If Troubleshoot requests the Pump and Electronics Unit (PEU) to be replaced, conduct the following inspection before removal of the PEU.

Check the DEF for contamination, if the relevant troubleshooting procedure has not instructed you to do so. Refer to "System Operation Testing and Adjusting", Diesel Exhaust Fluid Quality - Test for the correct procedure.

Inspect the DEF tank cap, DEF header filter, DEF pump filter for any visible obstruction

Illustration 1 g06152768

(1) DEF line in

(2) DEF line out

(3) DEF line out let connection

(4) DEF line inlet connection

(5) Injector DEF line

Inspect and photograph both ends of the DEF fluid lines. If the ends of the lines are damaged or swollen, replace the DEF lines. Refer to "Disassembly and Assembly", Diesel Exhaust Fluid Lines - Remove and Install.At the end of the service take another PSR irrespective of outcome. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.If the troubleshooting steps have required a component to be changed, hold all replaced components for 30 days for a possible Parts Return Request (PRR). Make sure to include the closed work order paperwork.In every instance submit a SIMSi report, complete with TIB number M0079072, CPI number 359775 and submit through the CPI feedback tool within the SIMSi.

Detailed description of symptom experienced and under what conditions issue occurred

Product Status Report (PSR) before and after troubleshooting. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.

Completed Troubleshooting steps tables. Refer to Tables 2, 3, and 4.

Details of DEF tank cap, DEF header filter, DEF pump filter, visual inspection

Photos of DEF fluid lines

Details

Have questions with 101402-2352?

Group cross 101402-2352 ZEXEL

Hino

Hino

Hino

Hino

101402-2352

9 400 613 869

220206091B

INJECTION-PUMP ASSEMBLY

W04D-T

W04D-T