Information injection-pump assembly

BOSCH

9 400 610 439

9400610439

ZEXEL

101402-2311

1014022311

HINO

220204971A

220204971a

Rating:

Service parts 101402-2311 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1710A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 439

9400610439

ZEXEL

101402-2311

1014022311

HINO

220204971A

220204971a

Zexel num

Bosch num

Firm num

Name

101402-2311

9 400 610 439

220204971A HINO

INJECTION-PUMP ASSEMBLY

W04C-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

W04C-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.17

3.23

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

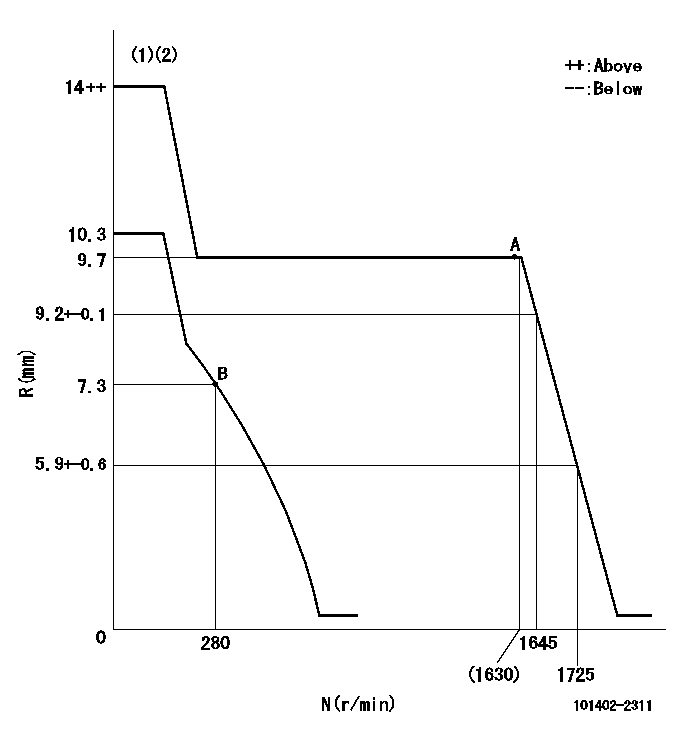

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

86

84

88

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.3+-0.5

Pump speed

r/min

280

280

280

Average injection quantity

mm3/st.

11.5

10

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

----------

K=10

----------

----------

K=10

----------

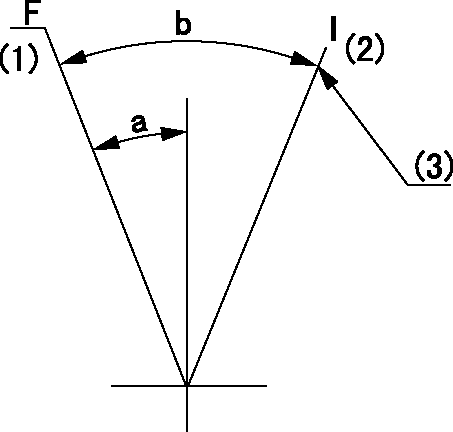

Speed control lever angle

F:Full speed

I:Idle

(1)-

(2)-

(3)Stopper bolt setting

----------

----------

a=17deg+-5deg b=30deg+-5deg

----------

----------

a=17deg+-5deg b=30deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=6.8mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=6.8mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Image1.5.1

2. Use 4 new grommets (MCI part number 97-2246-00002 (Dealer Order)) per bus. Grommets are to be installed between the clamp and chassis frame at same location as originals.

3. Clean existing exhaust inlet pipe with wire brush for reuse. Install new Exhaust clamps (Dealer Order).

4. Clean existing exhaust Outlet pipe with wire brush for reuse. Install new Exhaust clamps (Dealer Order).

5. Use a floor jack or transmission jack with CCRT properly secured to lift into place. Place a pipe clamp loosely over the inlet socket. Use the jack to raise the CCRT assembly into position. Insert exhaust pipe elbow into inlet socket. Tighten the clamp bolt to a torque of approximately 50 lb ft. Refer image 1.5.1.

Image1.6.1

6. Provide adequate clearance to Pro Heat exhaust pipe. Mounting brackets will have 1/2 inch slotted bolt holes. Orient to provide needed clearance. Refer image 1.6.1.

Image1.7.1

7. Install Thermocouple.

- Apply a thin coat of anti-seize to the threads of the Male Run Tee and thread it into the boss on the CCRT inlet. Image 1.7.1 shows a completed installation.

- All the parts used from Step 7 to Step 10 are included in the 219-7990 Installation Kit.

Image1.8.1

8. Insert the reducer fitting into the Tee fitting in line with the boss (Image 1.8.1). Tighten the lock nut (also use the Lock Washer) on the Tee until it is finger tight and then tighten it 1 1/4 turns with a 9/16" wrench.

Image1.9.1

9. Insert the thermocouple into the reducer as far as it will go, then pull it back 1/4 inch (Image 1.9.1). Tighten the lock nut finger tight and then tighten 1 1/4 turns with a 7/16" wrench. If necessary, the thermocouple may be bent ONCE to avoid any interference. Do not bend the thermocouple past 90 degrees.

NOTE. JM instructions instruct to insert probe and withdraw one inch. For this installation, insert probe and withdraw 1/4 inch to allow accurate temperature measurement of the exhaust.

Image1.10.1

10. Insert the copper tubing into the fitting on the Tee that is at a 90 degree angle to the boss (Image 1.10.1). Tighten the fitting on the Tee until it is finger tight. Then tighten it 1 1/4 turns with a 9/16" wrench.

Image1.11.1

Image1.11.2

11. Route the cable and copper tube and the secure cable with 6K0806 Cable Straps as shown. It is important to use these cable straps so the tube and cable are oriented in a way that they do not rub against the frame.

Install P brackets every two to three feet as needed. Refer in Image 1.11.2.

12. Install 271-6537 CCRT Diagnostic Module using Bolts (4M5282), Washers (8T4205), nut (6V8185) and Lock Washer (3B4504). Use carbide tip drill bit for drilling in stainless steel.

Image1.13.1

13. Install 282-0031 Remote Display monitor lights along with dealer fabricated Remote Display Bracket. Use self tapping screws (90064A581), Splice (1364877), Washer (4B4274), Locknut (031049) and screw (4B1232).

Image1.14.1

14. Connect power using 3A Fuse.

15. Install existing Pin insulator on the weatherpack plug that connects to the OEM harness at the firewall that provides power to the CRT module.

16. Download

Have questions with 101402-2311?

Group cross 101402-2311 ZEXEL

Hino

101402-2311

9 400 610 439

220204971A

INJECTION-PUMP ASSEMBLY

W04C-T

W04C-T