Information injection-pump assembly

BOSCH

F 019 Z10 571

f019z10571

ZEXEL

101402-2300

1014022300

HINO

220204960A

220204960a

Rating:

Service parts 101402-2300 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 571

f019z10571

ZEXEL

101402-2300

1014022300

HINO

220204960A

220204960a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.17

3.23

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

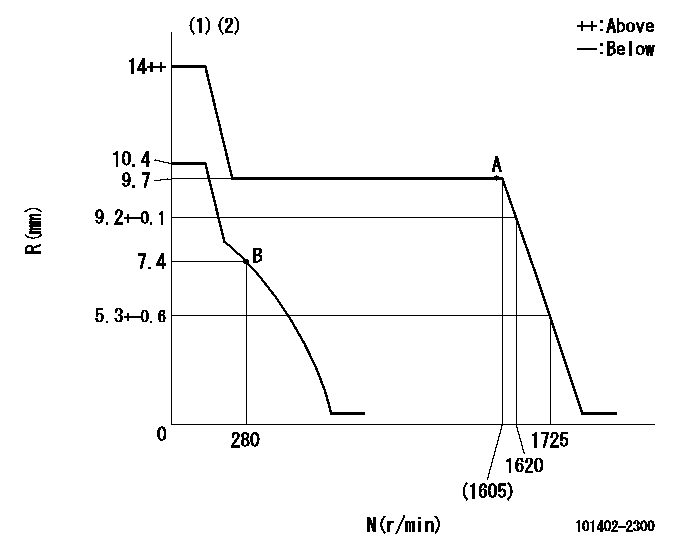

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

89

87

91

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.4+-0.5

Pump speed

r/min

280

280

280

Average injection quantity

mm3/st.

11.5

10

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

----------

K=8

----------

----------

K=8

----------

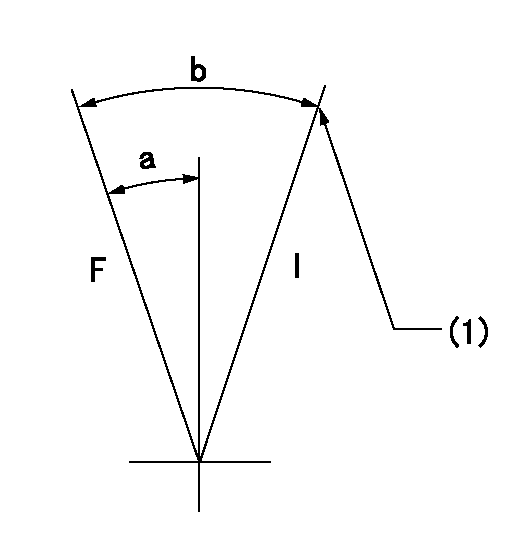

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=30deg+-5deg

----------

----------

a=16deg+-5deg b=30deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=6.9mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=6.9mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

ACTION REQUIRED

Check Plug Replacement:

1) Check engine serial number to ensure it is included in the affected rework population.

2) Inspect fuel injection pump outlet check plugs installed on pump. Refer to Image1 for check plug location. If the fuel injection pump outlet check plugs have dimples as shown in Image2 DO NOT perform plug rework.

3) If check plugs do not have dimples as shown in Image2 the plugs need to be replaced, refer to Special Instructions REHS3841 for proper plug installation.

Fuel Line Inspect and Possibly Replace:

Refer to Special Instructions REHS3842 for C7, and REHS3846 for C9. Inspect all high pressure fuel lines that require clamping to ensure proper clamping location and torque for each clamp that holds each high pressure fuel line in place. Verify all rubber grommets are present in each clamp. The fuel line(s) must be replaced if the clamp location/torque and or the grommets are not correct.

Reference line kit part numbers below for C7 and C9 if needed after inspection is complete.

DESCRIPTION______________________KIT

C7

Tube As.-Fuel_(Pump Line)______310-6027

Tube As.-Fuel_(Line 1)_________310-6029

Tube As.-Fuel_(Line 6)_________310-6030

C9

Tube As.-Fuel_(Pump Line)______310-6031

Tube As.-Fuel_(Line 1)_________310-6032

Tube As.-Fuel_(Lines 5 & 6)____310-6033

Image1

Image2

OWNER NOTIFICATION

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 1.0-hour job

Add an additional 0.2 Hrs per high pressure fuel line replaced in step 4 in the Action Required if needed.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Only return high pressure fuel line(s) replaced during this rework to the address below.

Make sure the outside of the shipping container is marked PIXXXX.

Caterpillar Inc.

Attn: PIXXXXX

Route 29 And Old Galena Road

Building DD, Dock 8,Engineering Parts Return Area

MOSSVILLE, IL 61552

USA

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

IMPORTANT: SAFETY

SAFETY ? RECALL FOR REPLACING THE FUEL PUMP PLUGS

MODELS INVOLVED - Certain C7 and C9 Truck and Bus Engines

Dear Caterpillar Product Owner:

This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act, and the requirements of the Canadian Motor Vehicle Safety Act. Caterpillar has decided that a defect which relates to motor vehicle safety exists in 2008 and 2009 model year trucks and buses equipped with certain Caterpillar C7 and C9 diesel engines.

A fuel pump plug may crack, which could cause fuel to spray and leak. Fuel in the presence of an ignition source can result in a fire. The driver may also become aware due to decrease in engine power or the illumination of a check engine lamp or engine protection lamp. New fuel pump plugs will be installed on the engine. You will not be charged for the service performed.

Please contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

If you are a lessor of these vehicles, you must forward this letter to your lessee within ten days.

If you have had your vehicle repaired for this concern prior to receipt of this notice and incurred any costs, you may be eligible for