Information injection-pump assembly

BOSCH

9 400 613 867

9400613867

ZEXEL

101402-2270

1014022270

HINO

220204380A

220204380a

Rating:

Service parts 101402-2270 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1710

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 867

9400613867

ZEXEL

101402-2270

1014022270

HINO

220204380A

220204380a

Zexel num

Bosch num

Firm num

Name

101402-2270

9 400 613 867

220204380A HINO

INJECTION-PUMP ASSEMBLY

W04C-T * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

W04C-T * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.17

3.23

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

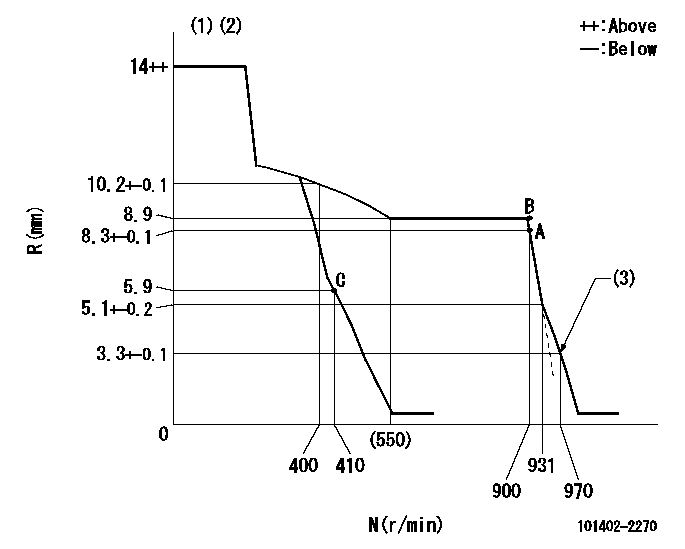

Injection quantity adjustment

Adjusting point

A

Rack position

8.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

72.5

70.5

74.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.9+-0.5

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

10

8.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

----------

K=16

----------

----------

K=16

----------

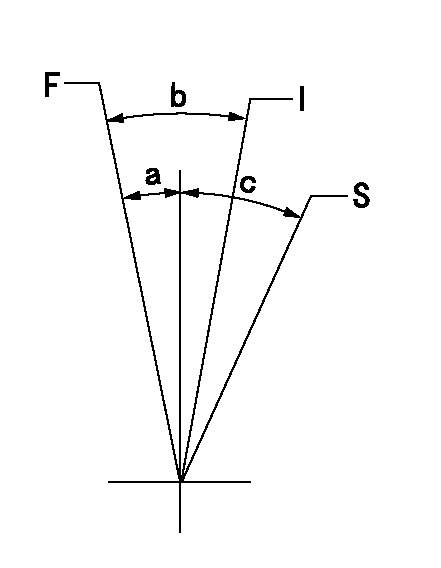

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=3deg+-5deg b=20deg+-5deg c=32deg+-3deg

----------

----------

a=3deg+-5deg b=20deg+-5deg c=32deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=5.4mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=5.4mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Image1.1.1

4) Remove the 90 degree pressure line fitting under the sensor box.

5) Remove the 90 degree pressure line fitting from the DPF center section that is closest to the outlet side.

6) The new pressure line that will fit into the DPF center section will need to be installed into the port in which the thermocouple was fitted. The existing thermocouple will need to be fitted into the port in which the old pressure line was fitted.

Swapping of the ports is only necessary on the outlet side of the center section.

Image1.2.1

Image1.2.2

7) Install the 7W-3556 washer on the 304-8042 straight fitting. Install the straight fitting into the DPF pressure port (towards the outlet side) in which the thermocouple was previously installed, tighten to a torque of 24 +/- 4 Nm (212 +/- 35 lb-in). Screw the 2N-8142 tee fitting onto that straight fitting and tighten to a torque of 24 +/- 4 Nm (212 +/- 35 lb-in).

Image1.3.1

8) Replace the O-ring on the sensor box where the old 90 degree pressure line fitting was located. Install the 4S-4857 tee fitting in the sensor box to a torque of 11 +/- 1 Nm (97 +/- 9 lb-in).

Image1.4.1

9) Where applicable, perform Service Letter REBE3391 at this time.

10) Install sensor box bracket and existing heat shield. Tighten all six bolts to a torque of 12 +/- 3 Nm (106 +/- 27 lb-in).

11) Install sensor box, new pressure lines (tube assemblies), thermocouples onto DPF, and cable straps.

Reference appropriate Disassembly and Assembly manual for proper torque and use of anti-seize.

Image1.5.1

12) Start the engine and use CAT ET to ensure that the status parameter Diesel Particulate Trap #1 Differential Pressure has a value greater than zero. Also, ensure status parameters Diesel Particulate Trap #1 Intake Temperature, and Diesel Particulate Trap #1 Outlet Temperature show reasonable values and increase with the rising exhaust temperatures.

Have questions with 101402-2270?

Group cross 101402-2270 ZEXEL

Hino

101402-2270

9 400 613 867

220204380A

INJECTION-PUMP ASSEMBLY

W04C-T

W04C-T