Information injection-pump assembly

BOSCH

9 400 613 864

9400613864

ZEXEL

101402-2241

1014022241

HINO

220204131A

220204131a

Rating:

Service parts 101402-2241 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2561A

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 864

9400613864

ZEXEL

101402-2241

1014022241

HINO

220204131A

220204131a

Zexel num

Bosch num

Firm num

Name

101402-2241

9 400 613 864

220204131A HINO

INJECTION-PUMP ASSEMBLY

W04C-T K 14BD INJECTION PUMP ASSY PE4AD PE

W04C-T K 14BD INJECTION PUMP ASSY PE4AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

4.4

4.35

4.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

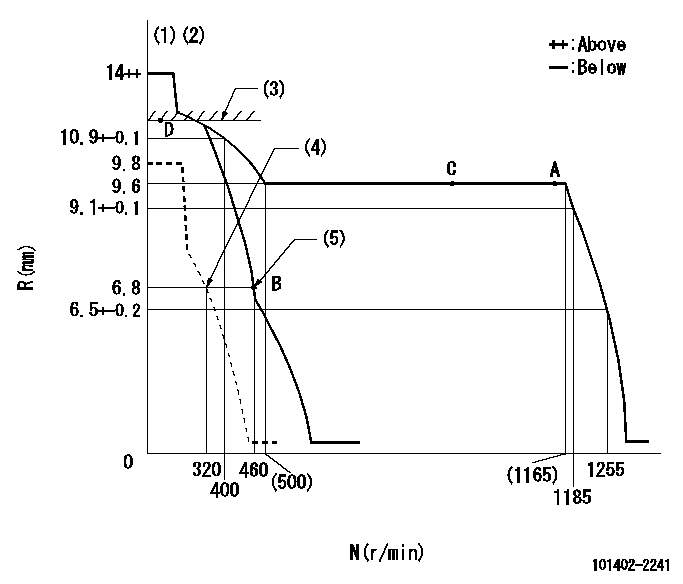

Injection quantity adjustment

Adjusting point

A

Rack position

9.6

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

68.5

66.5

70.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.4+-0.5

Pump speed

r/min

460

460

460

Average injection quantity

mm3/st.

11.5

10

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

105

105

115

Fixing the lever

*

Rack limit

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=11

----------

----------

K=11

----------

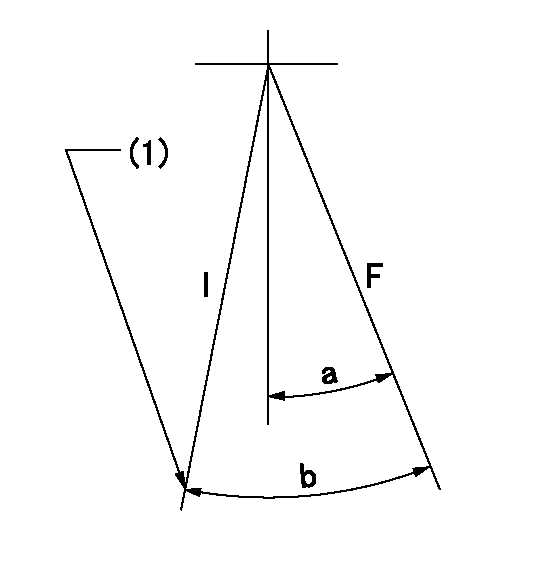

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(27deg)+-5deg b=(33deg)+-5deg

----------

----------

a=(27deg)+-5deg b=(33deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

PARTS NEEDED

Qty

Part Number Description

2 6V8260 SEAL-O-RING

1 10R6350 PUMP GP-FUEL

1 2923739 TUBE AS-FUEL

1 2923740 TUBE AS-FUEL

ACTION REQUIRED

This procedure only applies to engines with less than 250 hours.

Step 1: Verify oil level on the dipstick gage is at the full mark after engine has been shut off for 15 minutes. Adjust oil level if necessary and reconfirm oil level is at the full mark on gage before procedeing to Step 2.

Step 2: Use Cat Electronic Technician to run the Injector Fuel Delivery Test and repeat test for a total of four times. Test takes approximately 7 minutes for each run and is listed under the Diagnostic Test menu in Cat Electronic Technician.

Step 3: Shut engine off and recheck oil level after 15 minutes.

Result 1: If oil level did not rise return truck to service.

Result 2: If oil level has risen on gage due to fuel dilution, obtain an oil sample and replace high-pressure fuel pump, refer to RENR9707 Disassembly & Assembly guide for proper replacement of fuel injection pump. Maintain engine cleanliness and proper oil sampling practices at all times.

OWNER NOTIFICATION

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 1.0-hour job

Dealer to perform most economical repair.

Option 1: Inspection

1.0 hour only will be allowed for engines over 250 hours.

Description________________SMCS CODE________Hours

ECM Download_______________7751-001_________1.0

Option 2: Troubleshooting

1.6 hours will be allowed to perform troubleshooting.

Description________________SMCS CODE________Hours

ECM Download_______________7751-001_________1.0

Injector Diagnostic Test___1290-035_________0.6

Option 3: Pump Replacement

Description________________SMCS CODE________Hours

ECM Download_______________7751-001_________1.0

Injector Diagnostic Test___1290-035_________0.6

Oil Sample_________________1348-008-SM______0.2

Engine Wash________________1251-074_________0.3

R&I Pump __________________1251-010_________4.1

Minor Road Test____________1251-030_________0.5

Exception may be considered and claimed depending on chassis.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling. Return all parts replaced along with oil sample to address listed below for 100% inspection.

Caterpillar Inc.

Attn: PIXXXXX

BUILDING DD DOCK 8

ROUTE 29 OLD GALENA ROAD

MOSSIVILLE, IL 61552

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR INSPECTING FUEL INJECTION PUMPS ON CERTAIN C7/C9 ON-HIGHWAY TRUCK ENGINES

MODELS INVOLVED - C7/C9 ON-HIGHWAY TRUCK ENGINES

Dear Caterpillar Product Owner:

The fuel injection pump needs to be inspected on the products listed below. The existing fuel pump can cause fuel to mix with engine oil. You will not be charged for the service performed.

Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

Please refer the dealer to their Service Letter dated 10Oct2007 when scheduling this service.

We regret the inconvenience this may cause you, but urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 10Oct2007 Service Letter

Have questions with 101402-2241?

Group cross 101402-2241 ZEXEL

Hino

101402-2241

9 400 613 864

220204131A

INJECTION-PUMP ASSEMBLY

W04C-T

W04C-T