Information injection-pump assembly

BOSCH

9 400 613 857

9400613857

ZEXEL

101402-2140

1014022140

HINO

220203410A

220203410a

Rating:

Service parts 101402-2140 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1710

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 857

9400613857

ZEXEL

101402-2140

1014022140

HINO

220203410A

220203410a

Zexel num

Bosch num

Firm num

Name

101402-2140

9 400 613 857

220203410A HINO

INJECTION-PUMP ASSEMBLY

W04C-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

W04C-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.17

3.23

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

74

72

76

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.7+-0.5

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

22.8

21.3

24.3

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

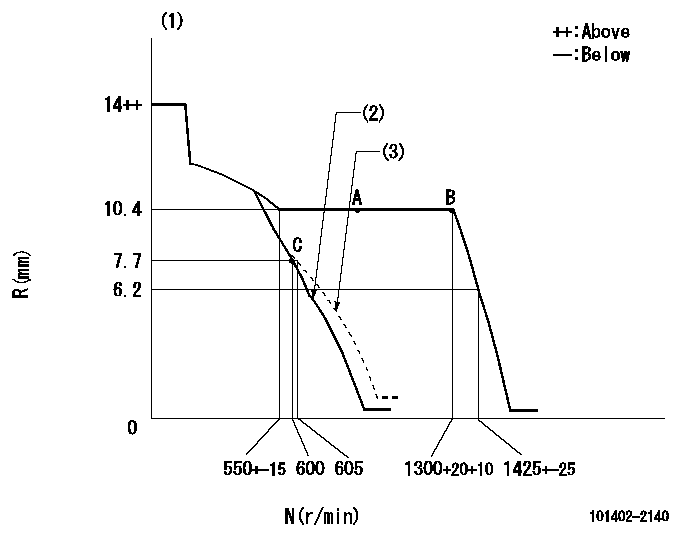

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Main spring setting

(3)Set idle sub-spring

----------

K=14

----------

----------

K=14

----------

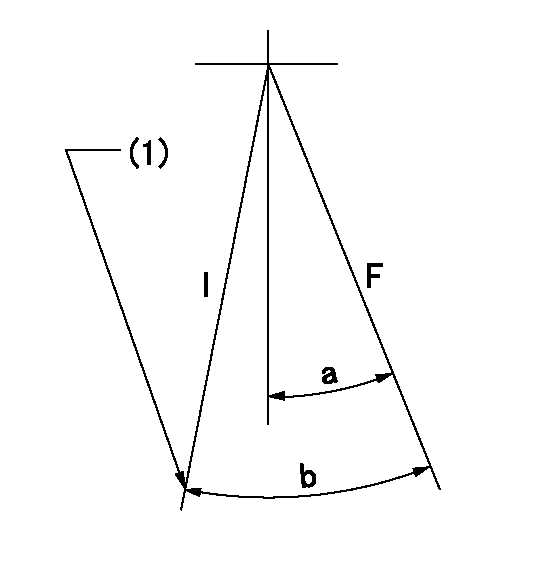

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=20deg+-5deg

----------

----------

a=16deg+-5deg b=20deg+-5deg

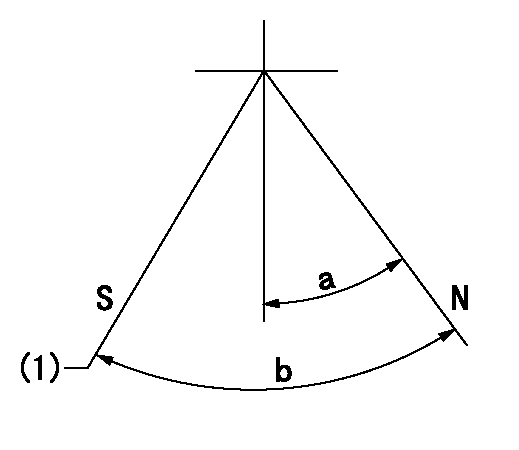

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

AUGUST 2010

INFORMATION RELEASE MEMO

Reman

PELJ1207 ?2010 Caterpillar CAT REMAN ANNOUNCES AN APPEARANCE CHANGE TO CERTAIN 3406 AND 3500 ELECTRONIC UNIT INJECTORS

Announcement

Cat Reman announces an appearance change to certain 3406 and 3500 electronic unit injectors. Effective immediately, certain remanufactured electronic unit injectors for 3406 and 3500 engines will be produced with stators, which have been ground slightly around the outside to remove potentially obsolete identification information. In many cases, these remanufactured injectors were previously produced with a metal sleeve around the outside of the stator to cover any potentially obsolete identifying information. Dealers will see both sleeved and ground stators for some period of time. This change will not impact quality, performance, form, fit, or function.

Effective immediately, Figure 1 and Figure 2 willboth represent acceptable appearance for the affected electronic unit injector part numbers. Table 1 lists all affected part numbers.

Core Acceptance

Core Acceptance Criteria for Cat Reman parts is simple, visual, and requires no special tools. Consult the Unit Injectors Electronic Core Acceptance Criteria (SELD0226) for complete details.

Warranty

Please consult the appropriate Caterpillar parts warranty statement for your area.

Core Management

Please refer to the Cat Core Management Information System (CMIS 2) Parts Information application describing all Cat Reman part/CAF and related information. Also refer to other CMIS 2 inquiry applications such as Customer Profiles, Inspection Reason Codes, Inspection Line Inquiry, Add Charge Information, Entitlement Activity, Entitlement Inquiry, CCR Inquiry, CCR Entry, Shipment Processing; Process Packaging Grief; and Reporting to properly manage core returns and monitor inspection performance. This information will be available to all dealers worldwide after your CMIS 2 conversion date. In the meantime, please continue to use the current CMIS Entitlement Parts Inquiry Screen describing the list of parts in a Core Acceptability Family (CAF) and related part number detail.

For the latest updates of Reman Policies and Core Management (SELD0122), Core Management Systems & Operations Procedures (SELD0040), and Shipping Instructions (SELD0039), go to the Reman Dealer website https://catreman.cat.com. If you have any questions regarding core return processing, feel free to call Corinth toll free at (800) 537-2928. Outside the US please refer to the Core section of the Reman website for appropriate contact information for your region.

For assistance with technical questions, call the Peoria Reman Technical Help Line also toll free at (888) 88-REMAN (outside the US call non-toll free +1-309-494-4342), or use our E-mail address--Reman_Help.

Have questions with 101402-2140?

Group cross 101402-2140 ZEXEL

Hino

101402-2140

9 400 613 857

220203410A

INJECTION-PUMP ASSEMBLY

W04C-T

W04C-T