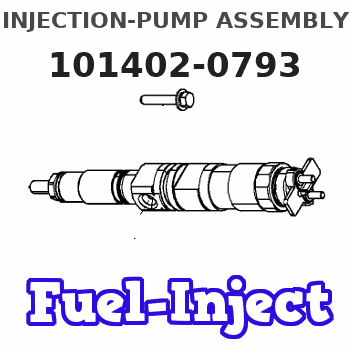

Information injection-pump assembly

BOSCH

9 400 610 320

9400610320

ZEXEL

101402-0793

1014020793

ISUZU

8944470493

8944470493

Rating:

Service parts 101402-0793 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-103-2

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}

15.

NOZZLE SET

Cross reference number

Zexel num

Bosch num

Firm num

Name

9 400 610 320

8944470493 ISUZU

INJECTION-PUMP ASSEMBLY

4BD1 * K 14BC PE4A,5A, PE

4BD1 * K 14BC PE4A,5A, PE

Information:

Illustration 4 g01341045

(6) Temperature Sensor

(7) Pressure Sensor

Mount the 271-7350 Warning Indicator Module Gp in a place that is easy to view. Ensure that the ambient temperature is below 45 °C (113 °F), and ensure that the Warning Indicator Module is not directly exposed to high pressure steam cleaning, solvents, the battery off gas, or electrical discharge. Note: The LED display panel may be installed in the cab of the vehicle.

Illustration 5 g01341118

(8) LED display panel

(9) ECM Installation for the Wiring Harness

The 274-7578 Monitor Electronic Control Module is provided with a 307-5521 Wire Harness.

Connect the 70 pin AMP to the ECM using a 160-7690 Connector Plug As. Tighten the Connector Screw for the ECM to 6 1 N m (4 0.73 lb ft).

Locate a 12 VDC or 24 VDC power supply that is always available even when the key is turned "OFF".

Connect the power wires from the wiring harness to the power supply. Install a 15 AMP fuse in this circuit. If an additional wire must be spliced, use a 14 gauge wire.

Attach the appropriate connectors to the pressure sensor, the temperature sensor, and the lamp group. Note: The service tool that is used in this installation is Caterpillar Electronic Technician (CAT ET). The service tool connector is a 9 pin Deutsch connector that contains the CDL (Caterpillar Data Link)/ATA, CAN/J1939, and power. A connection from the 274-7578 Monitor Electronic Control Module to the PC requires a Caterpillar Communications adapter, which connects to the PC via a serial port.The service tool (CAT ET) supports the following functions:

Download and review active alarms and logged alarms

Clear active alarms

View the data in real time.

Flash the diagnostic module.

Provide the capability for the user to configure certain parameters.Software Configuration

Refer to Systems Operation, Troubleshooting, Testing and Adjusting, KENR6695 for a description of controllable parameters and operation instructions.Once the 274-7578 Monitor Electronic Control Modulehas power, the 274-7578 Monitor Electronic Control Module will begin monitoring the pressure sensors and the temperature sensors.

Check whether CAT ET is configured with English or Metric units.

Set CAT ET to Metric units if a Metric unit is not already selected. Specifications

Table 3

System Requirements

Requirements for 12VDC or 24VDC System Value Notes

Operating Voltage Minimum +9V Minimum continuous operating voltage without damage to the ECM

Maximum Operating Voltage +32V Maximum continuous operating voltage without damage to the ECM

The voltage is over the maximum voltage that is allowed (two minutes continuous). +80V At 25 °C (77 °F)

Reverse Voltage (one hour) -32V At 85 °C (185 °F)

Power up voltage for the ECM +9V The minimum voltage for the ECM to internally run. Operating the engine at this voltage will cause the damage to the ECM.

The maximum current draw with key switch off 10mA

Maximum current draw with zero engine speed and no loads being driven 500mA

Maximum continuous operating current draw 10A This highly dependent upon the number and type of loads driven by the ECM

Recommended size for the Battery Fuse. 15A

Table 4

Operating Conditions

Thermal Conditions Vibrations Humidity Tolerance Salt Spray Tolerance Moisture Leakage Chemical Splash Immunity Electrostatic Environment

Operating Temperature Range: