Information injection-pump assembly

BOSCH

F 01G 09U 01E

f01g09u01e

ZEXEL

101401-9823

1014019823

Rating:

Service parts 101401-9823 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-19D02

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

F 01G 09U 01E

f01g09u01e

ZEXEL

101401-9823

1014019823

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.15

3.25

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

87

85.4

88.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.7+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

11.5

9.7

13.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.4)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

87

86

88

Basic

*

Fixing the lever

*

Boost pressure

kPa

73.3

73.3

Boost pressure

mmHg

550

550

Injection quantity adjustment_04

Adjusting point

B

Rack position

(R1+0.95

)+0.05-0

.1

Pump speed

r/min

1550

1550

1550

Average injection quantity

mm3/st.

101

97

105

Fixing the lever

*

Boost pressure

kPa

73.3

73.3

Boost pressure

mmHg

550

550

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2-1.4

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

55.5

51.5

59.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R2-1.4

Boost pressure

kPa

13.3

12

14.6

Boost pressure

mmHg

100

90

110

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R2(R1(13

.4))

Boost pressure

kPa

60

60

60

Boost pressure

mmHg

450

450

450

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1550

Advance angle

deg.

6

5.5

6.5

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

7

6.5

7.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

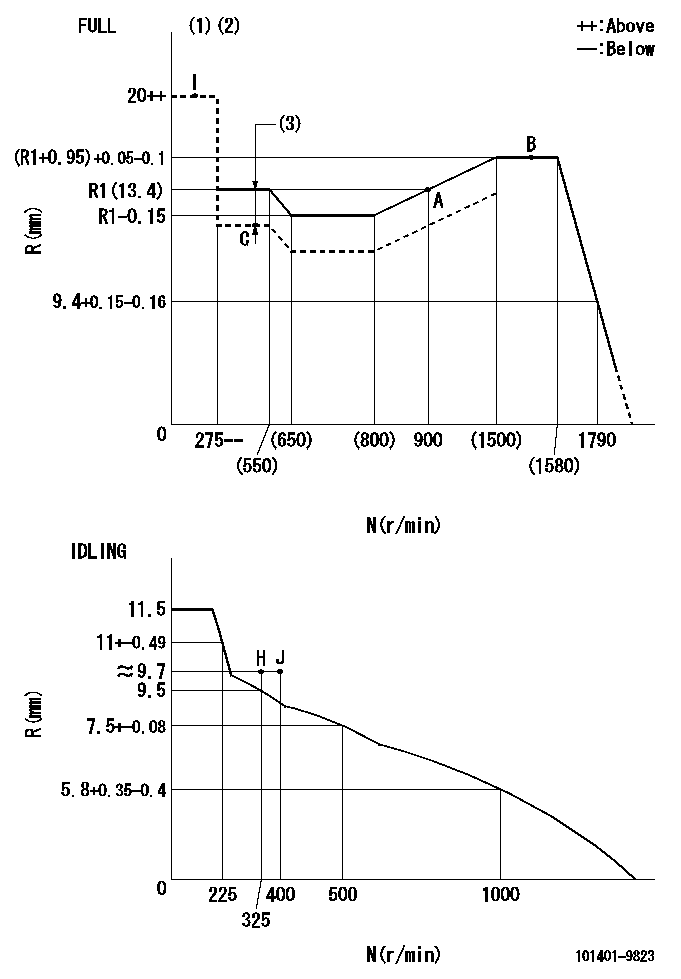

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=M32 BCL=1.4+-0.1mm

----------

----------

T1=M32 BCL=1.4+-0.1mm

----------

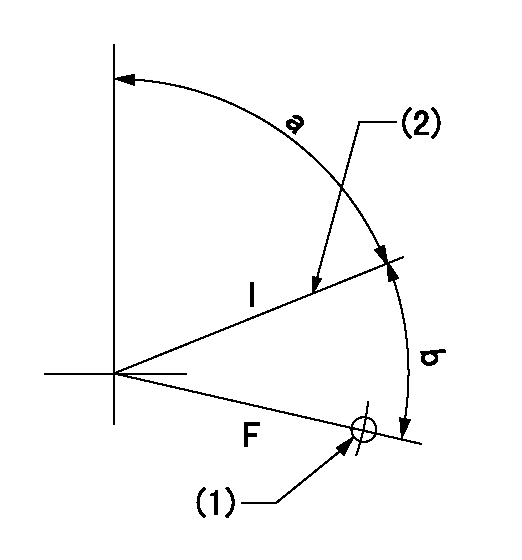

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=32mm

----------

a=71deg+-5deg b=37deg+-3deg

----------

aa=32mm

----------

a=71deg+-5deg b=37deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=15mm

----------

a=29deg+-5deg b=10deg+-5deg

----------

aa=15mm

----------

a=29deg+-5deg b=10deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=6deg

----------

a=(50deg)

----------

aa=6deg

----------

a=(50deg)

Information:

Ultra Low Sulfur Diesel (ULSD) poses a greater static ignition hazard than earlier diesel formulations, with a higher sulfur content, which may result in a fire or explosion. Consult with your fuel or fuel system supplier for details on proper grounding and bonding practices.

Note: The removal of sulfur and other compounds in Ultra Low Sulfur Diesel (ULSD) fuel decreases the conductivity of ULSD and increases the ability of the fuel to store static charge. Refineries may have treated the fuel with a static dissipating additive. However, there are many factors that can reduce the effectiveness of the additive over time. Static charges can build up in ULSD fuel while the fuel is flowing through fuel delivery systems. Static electricity discharge when combustible vapors are present could result in a fire or explosion. Therefore, ensuring that the entire system used to refuel your machine (fuel supply tank, transfer pump, transfer hose, nozzle, and others) is properly grounded and bonded is important. Consult with your fuel or fuel system supplier to ensure that the delivery system is in compliance with fueling standards for proper grounding and bonding practices.The two basic types of distillate diesel fuel are No. 2 diesel fuel and No. 1 diesel fuel. No. 2 diesel fuel is the most commonly available summer grade diesel fuel. No. 1 diesel fuel is a winter grade diesel fuel. During the winter months fuel suppliers will typically blend No. 1 and No. 2 diesel fuel in various percentages to meet the historical low ambient temperature cold-flow needs for a given area or region. No. 2 diesel fuel is a heavier diesel fuel than No. 1 diesel fuel. In cold weather, heavier fuels can cause problems with fuel filters, fuel lines, fuel tanks, and fuel storage. Heavier diesel fuels such as No. 2 diesel fuel can be used in diesel engines that operate in cold temperatures with an appropriate amount of a well proven pour point depressant additive. For more information on fuels which include blends of No. 1 and No. 2 diesel fuel, consult your fuel supplier.When you use No. 2 diesel fuel or other heavier fuels, some of the fuel characteristics may interfere with successful cold-weather operation. Additional information about the characteristics of diesel fuel is available. This information contains a discussion on the modification to the characteristics of diesel fuel. There are several possible methods that can be used to compensate for the fuel qualities that may interfere with cold-weather operation. These methods include the use of starting aids, engine coolant heaters, fuel heaters, and de-icers. In addition, the manufacturer of the fuel can add cold flow improvers and/or blend No. 1 and No. 2 diesel in various percentages.Not all areas of the world classify diesel fuel using the No. 1 and No. 2 nomenclature described above. But, the basic principles of using additives and/or blending fuels of different densities to help compensate for the fuel qualities that may interfere with cold-weather operation are the same.Starting Aids

The use of