Information injection-pump assembly

ZEXEL

101401-9770

1014019770

Rating:

Cross reference number

ZEXEL

101401-9770

1014019770

Zexel num

Bosch num

Firm num

Name

101401-9770

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.15

3.25

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

14.6

Pump speed

r/min

1550

1550

1550

Average injection quantity

mm3/st.

108.5

106.9

110.1

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

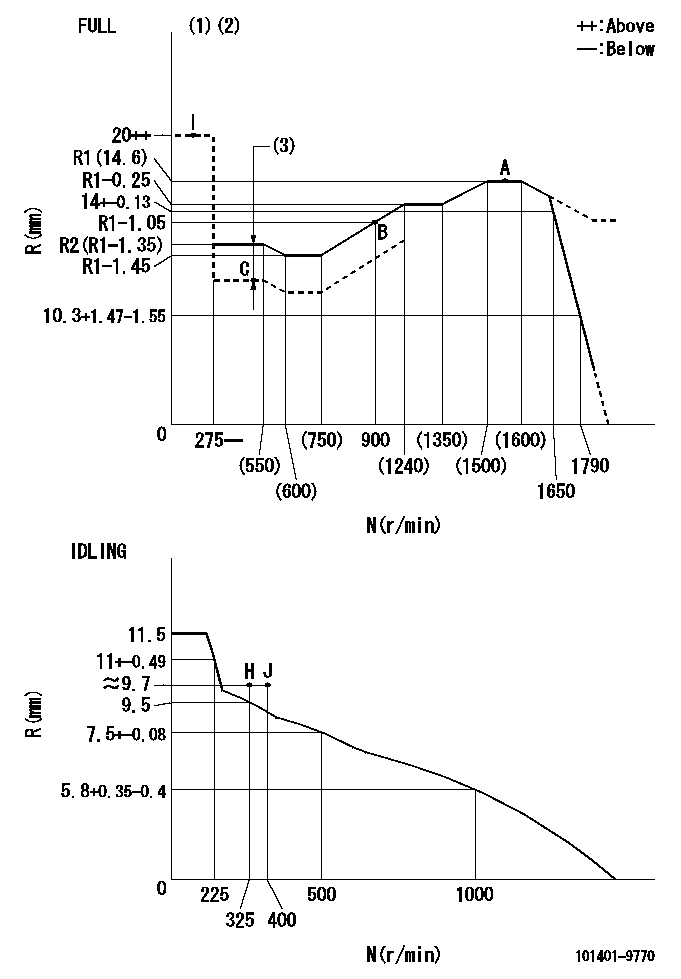

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.7+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

13

11.2

14.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(14.6)

Pump speed

r/min

1550

1550

1550

Average injection quantity

mm3/st.

108.5

107.5

109.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

70.6

70.6

Boost pressure

mmHg

530

530

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-1.05

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

88

84

92

Fixing the lever

*

Boost pressure

kPa

70.6

70.6

Boost pressure

mmHg

530

530

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2-0.95

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

58

54

62

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R2-0.95

Boost pressure

kPa

10.7

9.4

12

Boost pressure

mmHg

80

70

90

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R2(R1-1.

35)

Boost pressure

kPa

57.3

57.3

57.3

Boost pressure

mmHg

430

430

430

Timer adjustment

Pump speed

r/min

1000--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1550

Advance angle

deg.

5.1

4.6

5.6

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

7

6.5

7.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=L33 BCL=0.95+-0.1mm

----------

----------

T1=L33 BCL=0.95+-0.1mm

----------

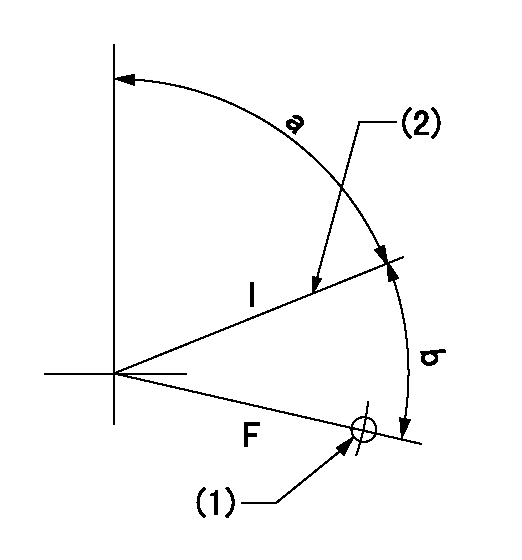

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=32mm

----------

a=71deg+-5deg b=(38deg)+-3deg

----------

aa=32mm

----------

a=71deg+-5deg b=(38deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=12mm

----------

a=29deg+-5deg b=10deg+-5deg

----------

aa=12mm

----------

a=29deg+-5deg b=10deg+-5deg

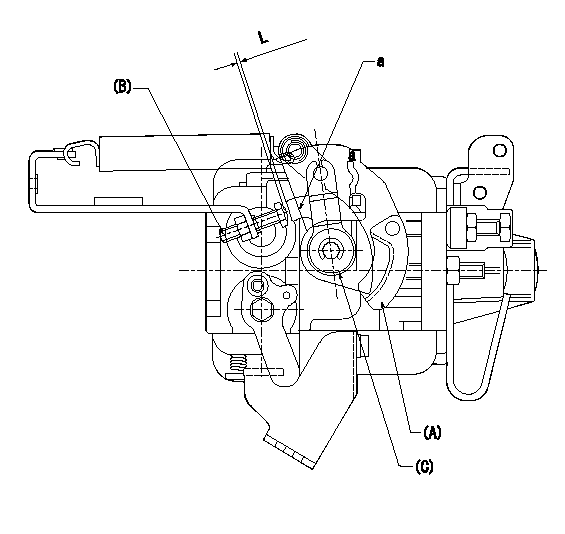

0000001501 LEVER

(A) Speed lever (lower)

(B) Stopper bolt

(C) Special lever (upper)

a:Point A (inside lever)

1. Special lever adjustment

(1)With the speed lever at the idle position, set the accelerator lever stopper bolt so that the accelerator lever contacts the speed lever at point a.

(2)Back off the stopper bolt L and set.

----------

L=1+0.5mm

----------

----------

L=1+0.5mm

----------

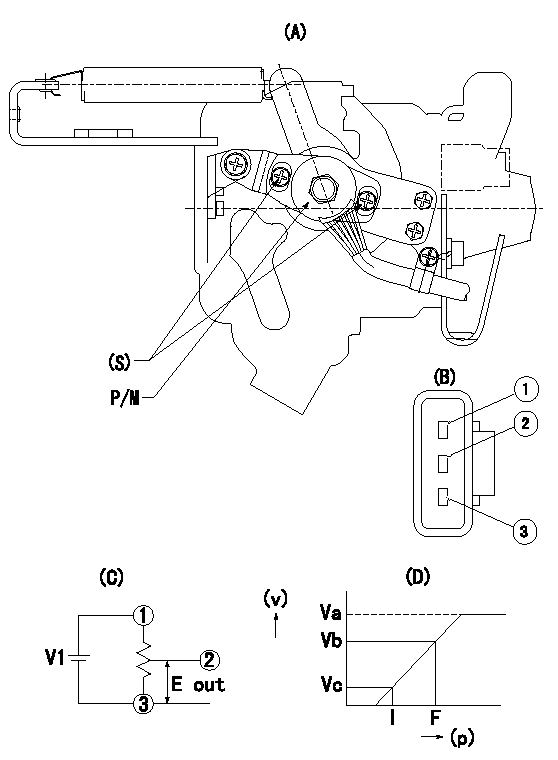

0000001601 POTENTIO METER

(A) : Governor plan view

(B): Potentiometer harness terminal

(C): Potentiometer connection diagram

(D) : Output voltage standard value

(S): Voltage

P/M: potentiometer

(v): output voltage (V)

(p): direction of potentiometer rotation

1. Adjustment procedures

(1)Apply DCV1 to potentiometer harness terminal (B) to obtain the specified output voltage.

(2)Fix the speed lever at the full side.

(3)Loosen the bolt (S), and move the potentiometer from left and right.

(4)Adjust so that the output voltage at full is within the standard values.

(5)Fix bolt (S).

(6)Repeatedly move the speed lever from the full side to the idle side.

(7)Check that it is within the standard values at full and idle.

----------

V1=5+-0.02V

----------

V1=5+-0.02V Va=(5)V Vb=(3.75)+-0.2V Vc=0.58+-0.3V

----------

V1=5+-0.02V

----------

V1=5+-0.02V Va=(5)V Vb=(3.75)+-0.2V Vc=0.58+-0.3V

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=5deg

----------

a=(50deg)

----------

aa=5deg

----------

a=(50deg)

Information:

Table 4 is an example for using the equation that is in Table 3.

Table 4

Example of the Equation for the Addition of Cat SCA To Water For Maintenance

Total Volume of the Cooling System (V) Multiplication

Factor Amount of Cat SCA that is Required (X)

946 L

(250 US gal) × 0.023 22 L

(6 US gal) Note: Specific engine applications may require maintenance practices to be periodically evaluated to maintain the engine cooling system properly.Cleaning the System of Heavy-Duty Coolant/Antifreeze

Before Cat SCA can be effective, the cooling system must be free from rust, scale, and other deposits. Preventive cleaning helps avoid downtime caused by expensive out-of-service cleaning required for extremelydirty and neglected cooling systems.Cat Cooling System Cleaners

Dissolves or depresses mineral scales, corrosion products, light oil contaminations, and sludges

Cleans the cooling system after used coolant is drained or before the cooling system is filled with new coolant

Cleans the cooling system whenever the coolant is contaminated or whenever the coolant is foaming

The “Standard” version of the Cat Cooling System Cleaners clean the cooling system while still in service.

Reduces downtime and cleaning costs

Helps avoid costly repairs from pitting and other internal problems caused by improper cooling system maintenance

Can be used with glycol-based antifreeze

For the recommended service interval, refer to the Operation and Maintenance Manual, "Maintenance Interval Schedule" for your engine.Cat Standard Cooling System Cleaners are designed to clean the cooling system of harmful scale and corrosion without removing the engine from service. The cleaners, both “Standard” and “Quick Flush” can be used in all Cat engine cooling systems. Consult your Cat dealer for part numbers.Note: These cleaners must not be used in systems that have been neglected or that have heavy scale buildup. These systems require a stronger commercial solvent that is available from local distributors.Prior to performing a cleaning of the cooling system, take a 1-liter (1-quart) sample of coolant from the engine while in operation into a clear container. Take the sample shortly after start-up while the coolant is not yet hot. The coolant should be adequately mixed by the water pump. Allow the sample

Table 4

Example of the Equation for the Addition of Cat SCA To Water For Maintenance

Total Volume of the Cooling System (V) Multiplication

Factor Amount of Cat SCA that is Required (X)

946 L

(250 US gal) × 0.023 22 L

(6 US gal) Note: Specific engine applications may require maintenance practices to be periodically evaluated to maintain the engine cooling system properly.Cleaning the System of Heavy-Duty Coolant/Antifreeze

Before Cat SCA can be effective, the cooling system must be free from rust, scale, and other deposits. Preventive cleaning helps avoid downtime caused by expensive out-of-service cleaning required for extremelydirty and neglected cooling systems.Cat Cooling System Cleaners

Dissolves or depresses mineral scales, corrosion products, light oil contaminations, and sludges

Cleans the cooling system after used coolant is drained or before the cooling system is filled with new coolant

Cleans the cooling system whenever the coolant is contaminated or whenever the coolant is foaming

The “Standard” version of the Cat Cooling System Cleaners clean the cooling system while still in service.

Reduces downtime and cleaning costs

Helps avoid costly repairs from pitting and other internal problems caused by improper cooling system maintenance

Can be used with glycol-based antifreeze

For the recommended service interval, refer to the Operation and Maintenance Manual, "Maintenance Interval Schedule" for your engine.Cat Standard Cooling System Cleaners are designed to clean the cooling system of harmful scale and corrosion without removing the engine from service. The cleaners, both “Standard” and “Quick Flush” can be used in all Cat engine cooling systems. Consult your Cat dealer for part numbers.Note: These cleaners must not be used in systems that have been neglected or that have heavy scale buildup. These systems require a stronger commercial solvent that is available from local distributors.Prior to performing a cleaning of the cooling system, take a 1-liter (1-quart) sample of coolant from the engine while in operation into a clear container. Take the sample shortly after start-up while the coolant is not yet hot. The coolant should be adequately mixed by the water pump. Allow the sample

Have questions with 101401-9770?

Group cross 101401-9770 ZEXEL

Mazda

Nissan-Diesel

Nissan-Diesel

101401-9770

INJECTION-PUMP ASSEMBLY