Information injection-pump assembly

ZEXEL

101401-9340

1014019340

Rating:

Cross reference number

ZEXEL

101401-9340

1014019340

Zexel num

Bosch num

Firm num

Name

101401-9340

DPICO

INJECTION-PUMP ASSEMBLY

4D31T * Q

4D31T * Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-6220

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54

53

55

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

10

8.7

11.3

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.5)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54

53

55

Basic

*

Fixing the lever

*

Boost pressure

kPa

37.3

37.3

Boost pressure

mmHg

280

280

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.3

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

68

64

72

Fixing the lever

*

Boost pressure

kPa

37.3

37.3

Boost pressure

mmHg

280

280

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1-0.

6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

37.5

33.5

41.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

D

Rack position

(R2+0.15

)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

28.5

24.5

32.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

67

67

72

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R1-0.6

Boost pressure

kPa

16

14.7

17.3

Boost pressure

mmHg

120

110

130

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

R1(10.5)

Boost pressure

kPa

30.7

24

30.7

Boost pressure

mmHg

230

180

230

Timer adjustment

Pump speed

r/min

1500--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1450

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1750

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

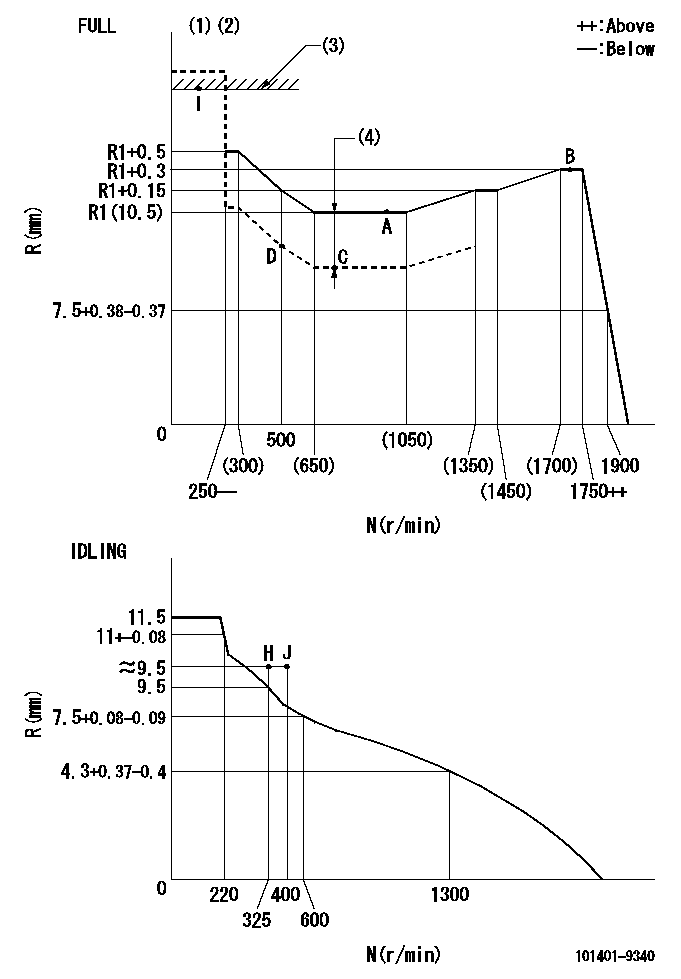

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=H93 BCL=0.6+-0.1mm

----------

----------

T1=H93 BCL=0.6+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=40mm

----------

a=26deg+-5deg b=42deg+-3deg

----------

aa=40mm

----------

a=26deg+-5deg b=42deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Free (at delivery)

(2)Use the hole at R = aa

(3)Rack position corresponding to bb

(4)Set the stopper bolt at speed = cc and rack position = dd (non-injection rack position). Confirm non-injection.

(5)After setting the stopper bolt, confirm non-injection at speed ee. Rack position = ff or less (non-injection rack position).

----------

aa=40mm bb=16mm cc=1700r/min dd=6.5-0.5mm ee=325r/min ff=(8)mm

----------

a=8deg+-5deg b=15deg+-5deg c=25deg+-5deg

----------

aa=40mm bb=16mm cc=1700r/min dd=6.5-0.5mm ee=325r/min ff=(8)mm

----------

a=8deg+-5deg b=15deg+-5deg c=25deg+-5deg

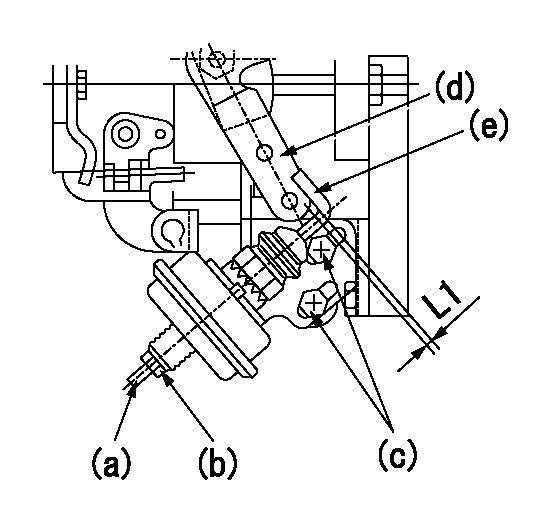

0000001501 ACTUATOR

(a) Screw

(B) Nut

Bolt c

(d) Speed lever

(e) Actuator shaft

1. Actuator adjustment procedure

(1)Position the speed lever (d) in the idle position.

(2)Set bolt (c) so that the clearance between the speed lever (d)'s pin and the actuator shaft (e) is approximately L1.

(3)Loosen the nut (b) and fully tighten the screw (a).

(4)Set the pump speed at N1 and read the rack position when negative pressure P1 is applied to the actuator.

(5)Gradually loosen screw (a) and fix the nut (b) when the pump speed is N2 and the rack position is R1.

(6)Apply negative pressure several times and confirm that the lever (d) returns to the idle position at negative pressure '0.'

(7)Confirm that rack position is R2 when negative pressure is P2.

----------

L1=2mm N1=500r/min P1=66.7kPa(500mmHg) N2=500r/min R1=9.1mm P2=66.7kPa(500mmHg) R2=9.1mm

----------

----------

L1=2mm N1=500r/min P1=66.7kPa(500mmHg) N2=500r/min R1=9.1mm P2=66.7kPa(500mmHg) R2=9.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(130deg)

----------

aa=14deg

----------

a=(130deg)

Information:

PARTS NEEDED

Qty

Part Number Description

1 6V8260 SEAL-O-RING

1 2147567 SEAL-O-RING-STOR

1 2147568 SEAL-O-RING-STOR

1 2287102 SEAL-O-RING-STOR

1 2842728 SENSOR GP-PRESS

1 2953099 PLUG-SPARK

1 2986488 SENSOR GP-PRESS

1 3003556 VALVE GP-SOL

1 3278044 VALVE GP-CHECK-A

2 3483425 GASKET

1 3790150 PUMP GP-FUEL

1 4154991 VALVE AS-RELIEF

1 4286096 KIT-F PUMP LINE

1 4333677 HEAD AS-COMB

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 31% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

1. Refer to Special Instruction, REHS5023, "Replacing the Fuel Injection Pump on Certain C9.3 Engines". Replace the existing 375-5244 common rail fuel injection pump with the 379-0150 common rail fuel injection pump and new gasket 6V-8260. Install a new 356-5214 fuel line from the common rail fuel injection pump to the fuel rail.

2. Refer to C9.3 Disassembly and Assembly, KENR8149 "Engines for Caterpillar Built Machines". Replace the prior 362-0770 common rail pressure relief valve with 415-4991 Pressure Relief Valve, and 228-7102 O-ring.

3. Replace the ARD manifold pilot and main fuel pressure sensors with 284-2728 Main Pressure Sensor and 214-7567 O-ring. Repeat the same procedure with the Pilot Pressure Sensor 298-6488 and 214-7568 O-ring.

4. Replace the 300-3556 Fuel Priming Pump Solenoid and replace the 327-8044 Fuel Priming Pump Check Valve.

5. Replace the existing ARD head with a 433-3677 Combustion Head and (2) 348-3425 Gaskets. Install a new 295-3099 Spark Plug.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-4000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

4001-6000 hrs,

25-36 mo 33.0% 50.0% 0.0% 0.0% 50.0% 50.0%

This is a 26.5-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101401-9340?

Group cross 101401-9340 ZEXEL

Dpico

101401-9340

INJECTION-PUMP ASSEMBLY

4D31T

4D31T