Information injection-pump assembly

BOSCH

F 019 Z10 469

f019z10469

ZEXEL

101401-9151

1014019151

Rating:

Service parts 101401-9151 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 469

f019z10469

ZEXEL

101401-9151

1014019151

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.2

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

92.2

90.2

94.2

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.4

6.9

9.9

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

94

94

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

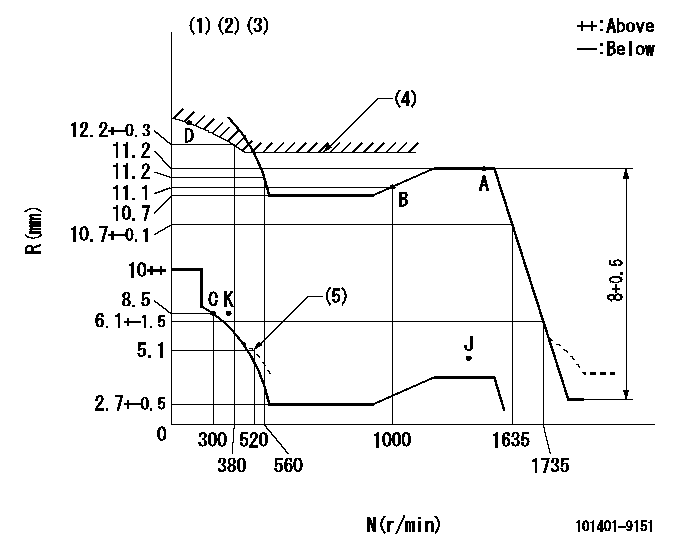

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Excess fuel setting for starting: SXL (N = N1)

(5)Damper spring setting

----------

RT=1 TH=2.2mm SXL=11.7+-0.1mm N1=500r/min

----------

----------

RT=1 TH=2.2mm SXL=11.7+-0.1mm N1=500r/min

----------

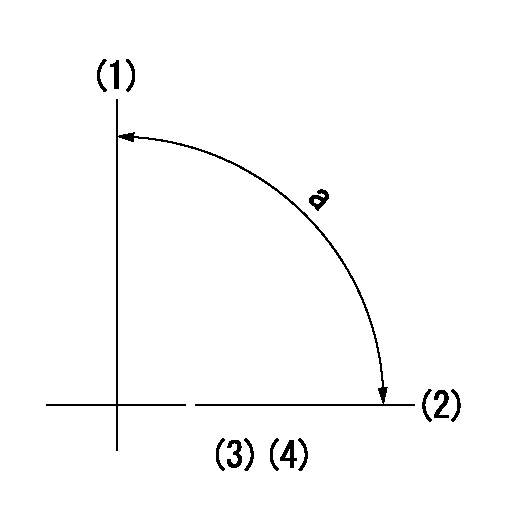

Speed control lever angle

F:Full speed

----------

----------

a=20.5deg+-5deg

----------

----------

a=20.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=29.5deg+-3deg

----------

----------

a=16deg+-5deg b=29.5deg+-3deg

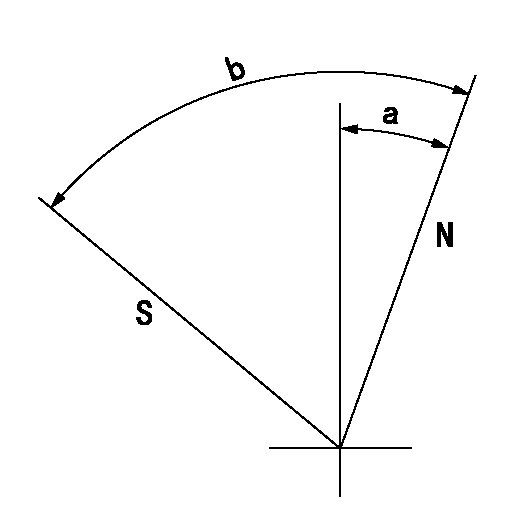

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=71deg+-5deg

----------

----------

a=20deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(90deg)

----------

aa=18deg

----------

a=(90deg)

Information:

Start By:a. remove vibration damper and crankshaft pulley

The crankshaft seal and wear sleeve come as a set and must not be separated from each other at any time. Carefully read Special Instruction, Form No. SMHS8508, that is included with each seal and wear sleeve before any handling of the seal group is made.

1. Use a sharp punch and a hammer to put four equally spaced holes in seal (1).2. Install the tip of Tool (A) into the seal, and use the slide hammer to pull it out of the timing gear housing. Change the location of Tool (A) in the seal in order to pull the seal out evenly. 3. Install 5P-7314 Distorter Ring (3) [part of Tooling (B)] in the space where the seal was removed.

Be careful not to damage the crankshaft surface.

4. Use 5P-7312 Distorter Ring (2) [part of Tooling (B)] to distort the wear sleeve. Put the end of the distorter in the space where the seal was removed.5. Turn the distorter to cause distortion to the wear sleeve. Move the distorter to another position, and turn the distorter again. Do this procedure until the wear sleeve is loose on the crankshaft.6. Remove the distorter, distorter ring and wear sleeve.Install Crankshaft Front Seal & Wear Sleeve

1. Fasten Tooling (A) to the crankshaft.2. Use 6V-1541 Quick Cure Primer to clean the outside diameter of the crankshaft flange and the inside diameter of the wear sleeve.3. Put 9S-3265 Retaining Compound on the outside diameter of the crankshaft flange and the inside diameter of the wear sleeve.

Do not separate the lip-type seal from the wear sleeve. The material in the large lip of the seal can be damaged easily. A scratch or rub (not visible) from a finger can damage the seal enough that it cannot be used. Install the sleeve in the seal. Once there is separation of the sleeve and lip-type seal they cannot be used again and must be replaced with a new seal group. Do not use any type of lubrication during installation of the seal group. If any type of lubrication is used in the installation of the seal group, early seal failure can result.

4. Put seal group (1) in position on Tooling (A). Be sure direction arrows on the seal are the same as crankshaft rotation.5. Put clean engine oil on the face of washer on nut (2) [part of Tooling (B)] that contacts the installer.

The front and rear seals and wear sleeves have different spiral grooves in the seal. Because of this type of design, the front seal group for an engine is different from the rear seal group. If a seal group is installed on the wrong end of the engine, oil can actually be taken out of the engine instead of moving the oil back into the engine.

6. Install Tooling (B) onto Tooling (A), and install nut (2) [part of Tooling (B)] on the threaded shaft of Tooling (A). 7. Tighten nut (2) until Tooling (B) contacts Tooling (A).8.

The crankshaft seal and wear sleeve come as a set and must not be separated from each other at any time. Carefully read Special Instruction, Form No. SMHS8508, that is included with each seal and wear sleeve before any handling of the seal group is made.

1. Use a sharp punch and a hammer to put four equally spaced holes in seal (1).2. Install the tip of Tool (A) into the seal, and use the slide hammer to pull it out of the timing gear housing. Change the location of Tool (A) in the seal in order to pull the seal out evenly. 3. Install 5P-7314 Distorter Ring (3) [part of Tooling (B)] in the space where the seal was removed.

Be careful not to damage the crankshaft surface.

4. Use 5P-7312 Distorter Ring (2) [part of Tooling (B)] to distort the wear sleeve. Put the end of the distorter in the space where the seal was removed.5. Turn the distorter to cause distortion to the wear sleeve. Move the distorter to another position, and turn the distorter again. Do this procedure until the wear sleeve is loose on the crankshaft.6. Remove the distorter, distorter ring and wear sleeve.Install Crankshaft Front Seal & Wear Sleeve

1. Fasten Tooling (A) to the crankshaft.2. Use 6V-1541 Quick Cure Primer to clean the outside diameter of the crankshaft flange and the inside diameter of the wear sleeve.3. Put 9S-3265 Retaining Compound on the outside diameter of the crankshaft flange and the inside diameter of the wear sleeve.

Do not separate the lip-type seal from the wear sleeve. The material in the large lip of the seal can be damaged easily. A scratch or rub (not visible) from a finger can damage the seal enough that it cannot be used. Install the sleeve in the seal. Once there is separation of the sleeve and lip-type seal they cannot be used again and must be replaced with a new seal group. Do not use any type of lubrication during installation of the seal group. If any type of lubrication is used in the installation of the seal group, early seal failure can result.

4. Put seal group (1) in position on Tooling (A). Be sure direction arrows on the seal are the same as crankshaft rotation.5. Put clean engine oil on the face of washer on nut (2) [part of Tooling (B)] that contacts the installer.

The front and rear seals and wear sleeves have different spiral grooves in the seal. Because of this type of design, the front seal group for an engine is different from the rear seal group. If a seal group is installed on the wrong end of the engine, oil can actually be taken out of the engine instead of moving the oil back into the engine.

6. Install Tooling (B) onto Tooling (A), and install nut (2) [part of Tooling (B)] on the threaded shaft of Tooling (A). 7. Tighten nut (2) until Tooling (B) contacts Tooling (A).8.