Information injection-pump assembly

BOSCH

9 400 613 755

9400613755

ZEXEL

101401-7352

1014017352

ISUZU

8971467870

8971467870

Rating:

Include in #1:

101603-2034

as _

Cross reference number

BOSCH

9 400 613 755

9400613755

ZEXEL

101401-7352

1014017352

ISUZU

8971467870

8971467870

Zexel num

Bosch num

Firm num

Name

101401-7352

9 400 613 755

8971467870 ISUZU

INJECTION-PUMP ASSEMBLY

4HF1 * K

4HF1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

4.1

4.05

4.15

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

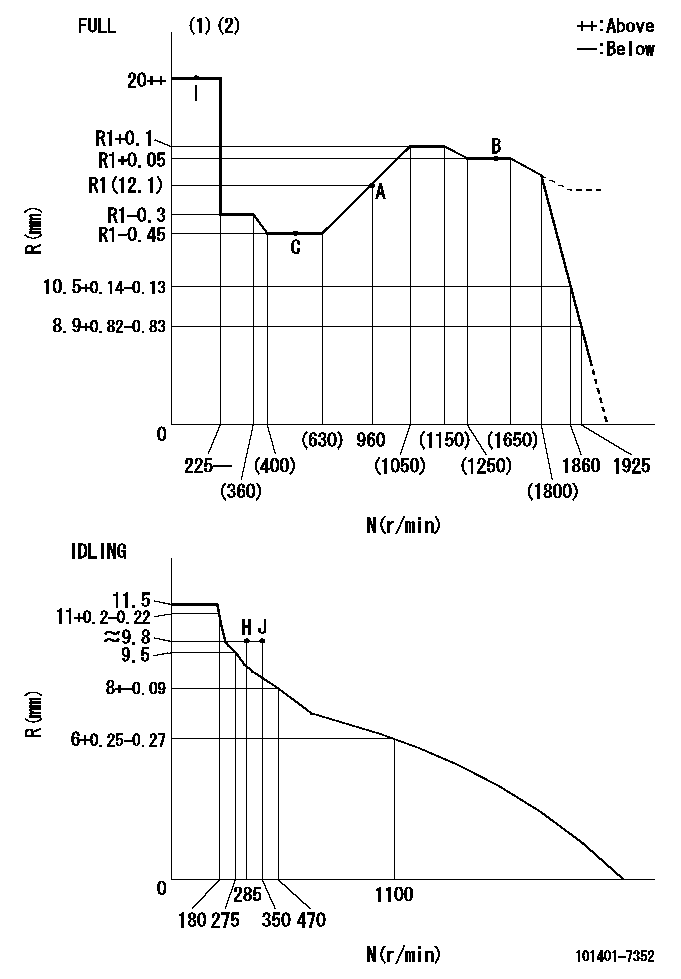

Injection quantity adjustment

Adjusting point

-

Rack position

12.1

Pump speed

r/min

960

960

960

Average injection quantity

mm3/st.

60

58.4

61.6

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.8+-0.5

Pump speed

r/min

285

285

285

Average injection quantity

mm3/st.

15.5

14.2

16.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.1)

Pump speed

r/min

960

960

960

Average injection quantity

mm3/st.

60

59

61

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.05

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

70

66

74

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.45

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

44

40

48

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=L31

----------

----------

T1=L31

----------

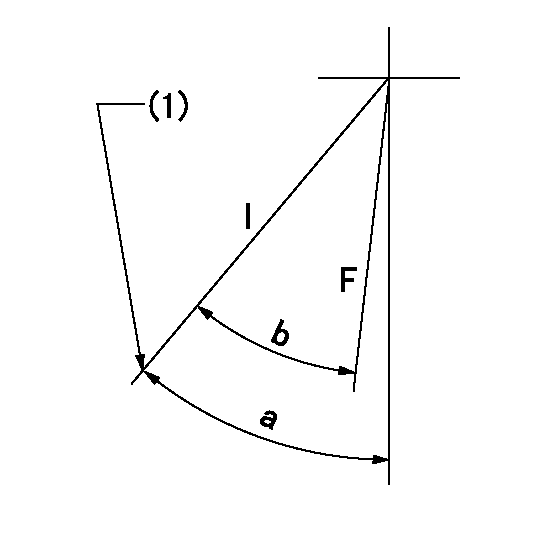

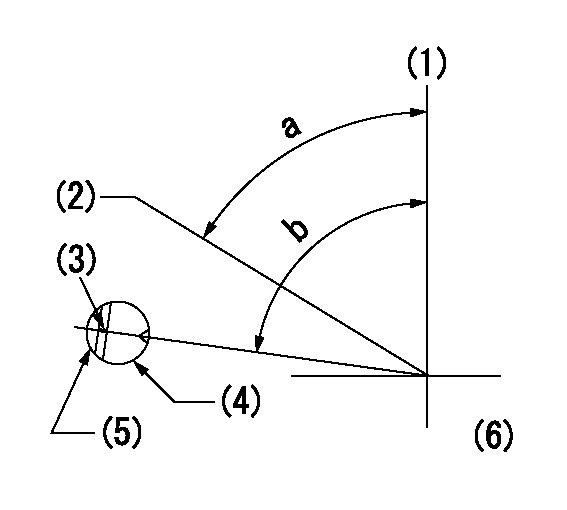

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=41deg+-5deg b=35.5deg+-3deg

----------

----------

a=41deg+-5deg b=35.5deg+-3deg

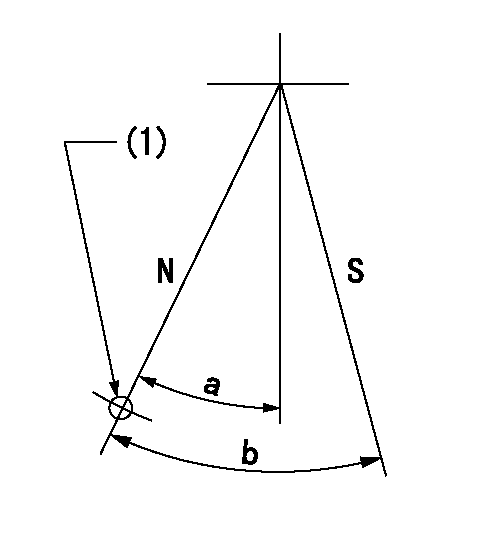

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

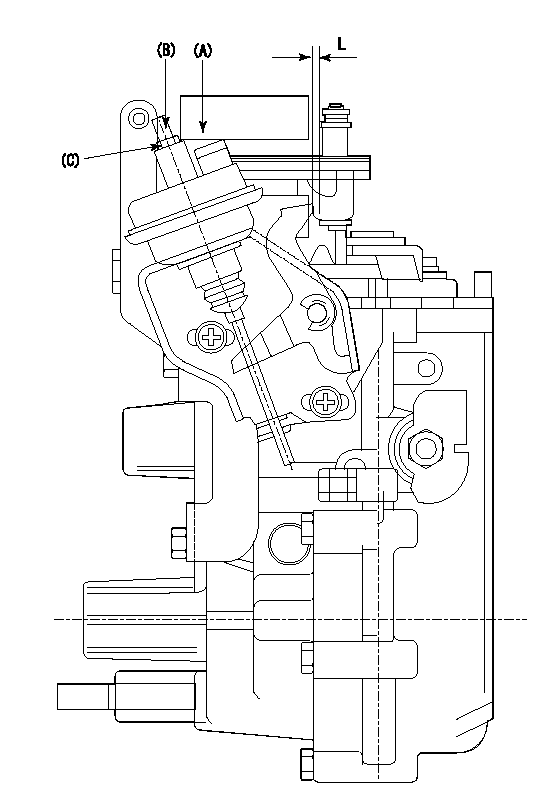

0000001501 FICD

(A) applied negative pressure

(B) Screw

(c) Nut

1. Set the actuator as described below.

(1)Confirm that there is clearance between the actuator lever and the speed lever.

(2)Loosen the nut (C).

(3)Push in the screw (B).

(4)Apply P1 from the actuator (A) part.

(5)Pull out the screw (B) slowly.

(6)Tighten and fix the nut (C) when pump speed is Na and the rack position is Ra.

(7)Torque the nut (C) to T1.

(8)Apply P2 several times.

(9)Confirm that the actuator functions normally.

(10)Confirm that there is a clearance between the actuator lever and the speed lever at that time.

----------

P1=53.3kPa(400mmHg) P2=53.3kPa(400mmHg) Na=400r/min Ra=9.5+-0.1mm T1=1.2~1.6N-m(0.12~0.16kgf-m)

----------

L=(5)mm

----------

P1=53.3kPa(400mmHg) P2=53.3kPa(400mmHg) Na=400r/min Ra=9.5+-0.1mm T1=1.2~1.6N-m(0.12~0.16kgf-m)

----------

L=(5)mm

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)Stamping position on the A/T outer rim

(4)Pump bracket check hole position.

(5)At the No 1 cylinder's beginning of injection, align with the projection seen through the bracket's check hole and mark the A/T's bevel C1.

(6)B.T.D.C.: aa

----------

aa=8deg

----------

a=(60deg) b=(85deg)

----------

aa=8deg

----------

a=(60deg) b=(85deg)

Information:

Aftermarket deviceA device or accessory installed by the customer after the vehicle is delivered. Air-To-Air Aftercooler (ATAAC)A means of cooling intake air after the turbocharger, using ambient air for cooling. The intake air is passed through an aftercooler (heat exchanger) mounted in front of the radiator before going to the intake manifold. Alternating Current (AC)The type of current where the direction of current flow changes (alternates) regularly and constantly. American Wire Gauge (AWG)A measure of the diameter (and therefore the current carrying ability) of electrical wire. The smaller the AWG number, the larger the wire. Before Top Dead Center (BTDC) or Before Top Center (BTC)The 180° of crankshaft rotation before the piston reaches Top Dead Center (normal direction of rotation). Boost Pressure SensorThis sensor measures inlet manifold air pressure and sends a signal to the ECM.. Bypass CircuitA circuit, usually temporary, to substitute for an existing circuit, typically for test purposes. CalibrationAs used here, is an electronic adjustment of a sensor signal. CodeSee Diagnostic Code. Customer Specified ParameterA Parameter that can be changed and whose value is set by the customer. Protected by Customer Passwords. Data LinkAn electrical connection for communication with other microprocessor based devices that are compatible with SAE Standard J1708/J1587 such as, electronic dashboards and maintenance systems. The Data Link is also the communication medium used for programming and troubleshooting with Caterpillar service tools. Desired RPMAn input to the electronic governor within the ECM. The electronic governor uses inputs from the Throttle Position Sensor, Engine Speed Sensor, and Customer Parameters to determine "Desired RPM". Desired Timing Advance ("Des Timing Adv" on ECAP)The injection timing advance calculated by the ECM as required to meet emission and performance specifications. Diagnostic CodeSometimes referred to as a "fault code", it is an indication of a problem or event in the 3176 System. Diagnostic LampSometimes referred to as the "check engine light", it is used to warn the operator of the presence of an active diagnostic code. Digital Diagnostic Tool (DDT)A Caterpillar Electronic Service Tool used for programming and diagnosing of the 3176 System. Direct CurrentThe type of current where the direction of current flow is consistently in one direction only. Duty CycleSee Pulse Width Modulation. Electronic Control Analyzer and Programmer (ECAP)A Caterpillar Electronic Service Tool used for programming and diagnosing a variety of electronic controls. An ECAP is needed for advanced diagnostic and programming functions not possible with a DDT. Electronic Control Module (ECM)The engine control computer that provides power to the 3176 electronics, monitors 3176 inputs and acts as a governor to control engine rpm. Electronic Engine Control (3176)The complete electronic system that monitors and controls engine operation under all conditions. Electronically Controlled Unit InjectorThe injection pump which is a mechanically actuated, electronically controlled unit injector combining the pumping, electronic fuel metering and injecting elements in a single unit. Engine Speed/Timing SensorProvides a Pulse Width Modulated Signal to the ECM, which the ECM interprets as crankshaft position and engine speed. Estimated Dynamic TimingThe ECM's estimate of

Have questions with 101401-7352?

Group cross 101401-7352 ZEXEL

Isuzu

Nissan

Isuzu

Nissan

Isuzu

Isuzu

Isuzu

Isuzu

Isuzu

Isuzu

101401-7352

9 400 613 755

8971467870

INJECTION-PUMP ASSEMBLY

4HF1

4HF1