Information injection-pump assembly

BOSCH

9 400 613 752

9400613752

ZEXEL

101401-7322

1014017322

ISUZU

8971467800

8971467800

Rating:

Service parts 101401-7322 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-97119-812-0

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 752

9400613752

ZEXEL

101401-7322

1014017322

ISUZU

8971467800

8971467800

Zexel num

Bosch num

Firm num

Name

101401-7322

9 400 613 752

8971467800 ISUZU

INJECTION-PUMP ASSEMBLY

4HF1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4HF1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

4.1

4.05

4.15

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12

Pump speed

r/min

960

960

960

Average injection quantity

mm3/st.

57

55.4

58.6

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.8+-0.5

Pump speed

r/min

285

285

285

Average injection quantity

mm3/st.

15.5

14.2

16.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12)

Pump speed

r/min

960

960

960

Average injection quantity

mm3/st.

57

56

58

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.1

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

68.5

64.5

72.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.2

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

45.1

41.1

49.1

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

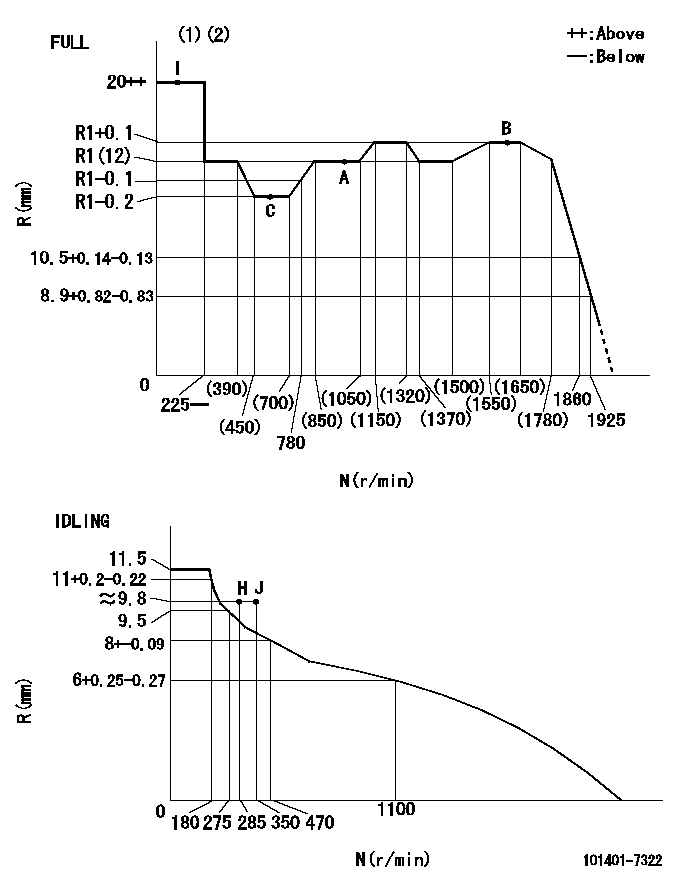

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=L48

----------

----------

T1=L48

----------

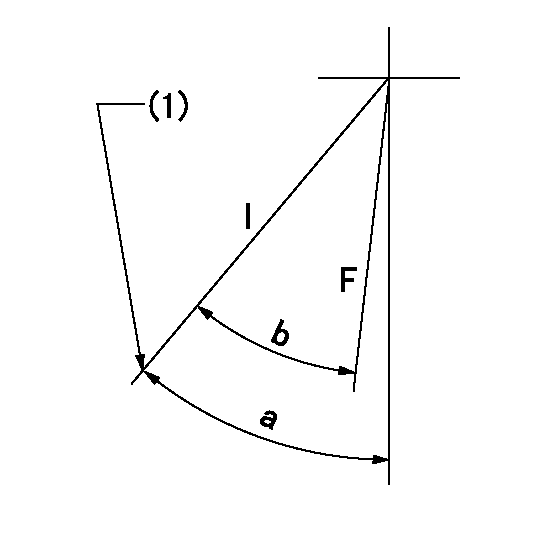

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=41deg+-5deg b=35.5deg+-3deg

----------

----------

a=41deg+-5deg b=35.5deg+-3deg

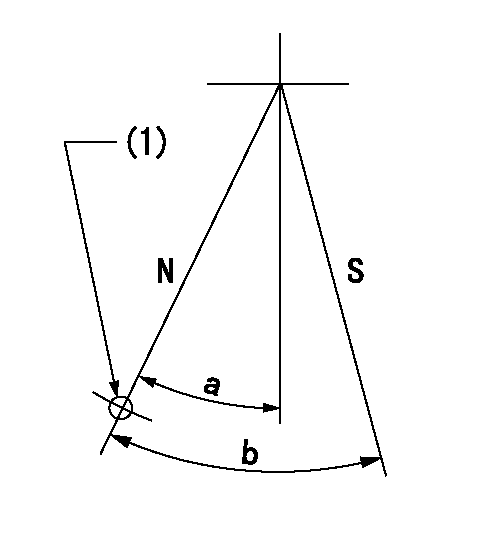

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

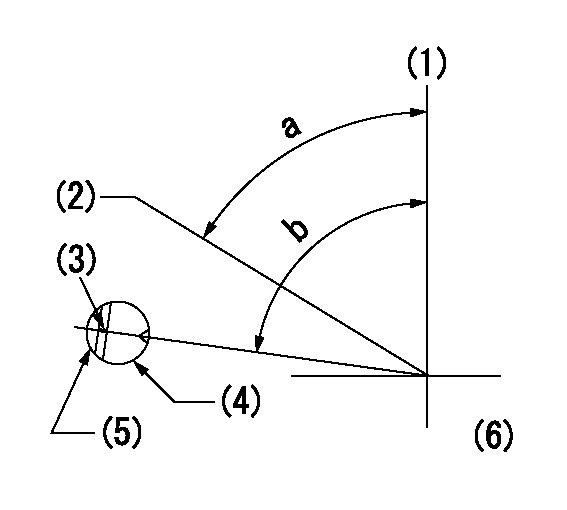

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)Stamping position on the A/T outer rim

(4)Pump bracket check hole position.

(5)At the No 1 cylinder's beginning of injection, align with the projection seen through the bracket's check hole and mark the A/T's bevel C1.

(6)B.T.D.C.: aa

----------

aa=8deg

----------

a=(60deg) b=(85deg)

----------

aa=8deg

----------

a=(60deg) b=(85deg)

Information:

Piston Group.(1) Crater. The piston is a symmetrical piston with an "on center" crater. Thoroughly lubricate piston group 360° in zone (A) with clean engine oil prior to inserting into the block group.(2) Top piston ring. Install ring with side marked "UP-1" toward top of piston (yellow color stripe to right of ring end gap).Clearance between ends of piston ring when installed in a cylinder liner with a bore size of 125.000 mm (4.9213 in) ... 0.625 0.125 mm (.0250 .0050 in)Increase in clearance between ends of piston ring for each 0.03 mm (.001 in) increase in cylinder liner bore size ... 0.09 mm (.004 in)(3) Intermediate piston ring. Install ring with side marked "UP-2" toward top of piston (green color stripe to right of ring end gap).Width of groove in piston for intermediate ring (new) ... 3.061 0.013 mm (.1032 .0005 in)Depth of groove in piston for intermediate ring (new) ... 3.727 mm (.1467 in)Thickness of intermediate ring (new) ... 2.990 0.010 mm (.1177 .0004 in)Clearance between groove and intermediate ring (new) ... 0.048 to 0.094 mm (.0002 to .0037 in)Clearance between ends of piston ring when installed in a cylinder liner with a bore size of 125.000 mm (4.9213 in) ... 0.625 0.125 mm (.0250 .0050 in)Increase in clearance between ends of piston ring for each 0.03 mm (.001 in) increase in cylinder liner bore size ... 0.09 mm (.004 in)(4) Oil regulating piston ring. Oil ring spring ends to be assembled 180° from ring end gap (white colored portion of spring must be visible at ring end gap).Width of groove in piston for oil ring (new) ... 4.033 0.013 mm (.1588 .0005 in)Depth of groove in piston for oil ring (new) ... 3.727 mm (.1467 in)Thickness of oil ring (new) ... 3.987 0.013 mm (.1570 .0005 in)Clearance between groove and oil ring (new) ... 0.020 to 0.072 mm (.0008 to .0028 in)Clearance between ends of piston ring when installed in a cylinder liner with a bore size of 125.000 mm (4.9213 in) ... 0.55 0.15 mm (.022 .006 in)Increase in clearance between ends of piston ring for each 0.03 mm (.001 in) increase in cylinder liner bore size ... 0.09 mm (.004 in)After piston rings have been installed, rotate rings so the end gaps are 120° apart.(5) Crown assembly.(6) Piston pin bore diameter in piston skirt ... 51.15 0.15 mm (2.014 .006 in)Thoroughly lubricate piston pin with clean engine oil prior to inserting into piston group and rod assembly.(7) Piston skirt.

Have questions with 101401-7322?

Group cross 101401-7322 ZEXEL

Isuzu

Nissan

Isuzu

Nissan

Isuzu

Isuzu

Isuzu

101401-7322

9 400 613 752

8971467800

INJECTION-PUMP ASSEMBLY

4HF1

4HF1