Information injection-pump assembly

BOSCH

9 400 613 750

9400613750

ZEXEL

101401-7295

1014017295

ISUZU

8971467781

8971467781

Rating:

Service parts 101401-7295 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 750

9400613750

ZEXEL

101401-7295

1014017295

ISUZU

8971467781

8971467781

Zexel num

Bosch num

Firm num

Name

101401-7295

9 400 613 750

8971467781 ISUZU

INJECTION-PUMP ASSEMBLY

4HE1-T K

4HE1-T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-3920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

3.8

3.75

3.85

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.1

Pump speed

r/min

1160

1160

1160

Average injection quantity

mm3/st.

97

95.4

98.6

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.8+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

14.5

13.2

15.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.1)

Pump speed

r/min

1160

1160

1160

Average injection quantity

mm3/st.

97

96

98

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

96.5

92.5

100.5

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2-0.45

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

86

82

90

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

95

95

111

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R2-0.45

Boost pressure

kPa

27.3

26

28.6

Boost pressure

mmHg

205

195

215

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

R2(R1-0.

6)

Boost pressure

kPa

46.7

46.7

46.7

Boost pressure

mmHg

350

350

350

Timer adjustment

Pump speed

r/min

1185--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1135

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1450

Advance angle

deg.

4.8

4.3

5.3

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

5

4.5

5.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

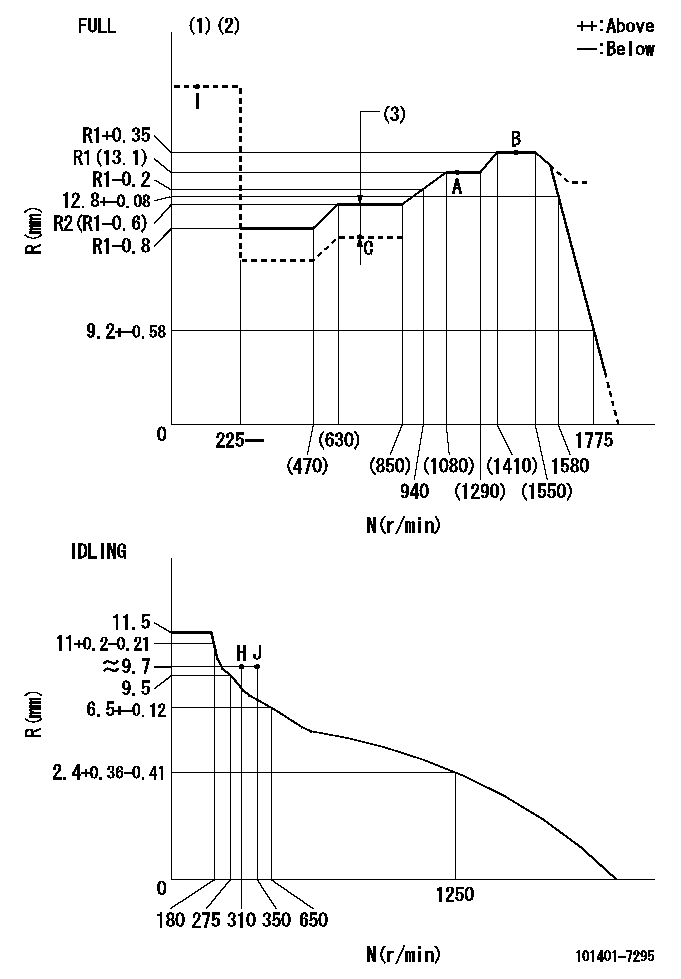

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=K06 BCL=0.45+-0.1mm

----------

----------

T1=K06 BCL=0.45+-0.1mm

----------

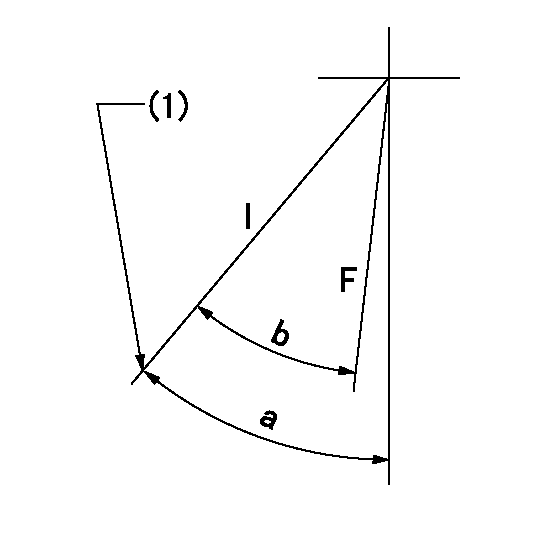

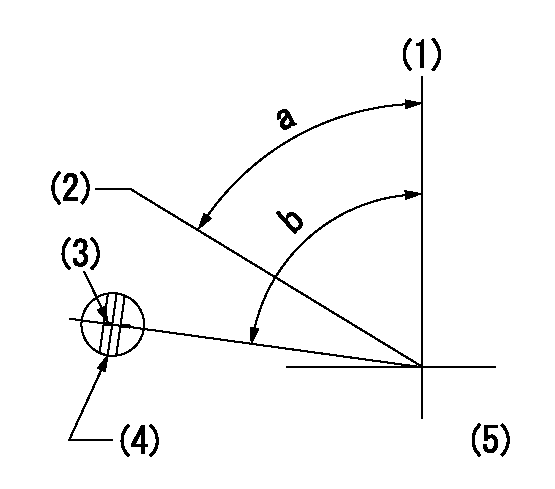

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H' (rack position = aa, speed = bb)

----------

aa=(9.7)mm bb=310r/min

----------

a=40deg+-5deg b=(39deg)+-3deg

----------

aa=(9.7)mm bb=310r/min

----------

a=40deg+-5deg b=(39deg)+-3deg

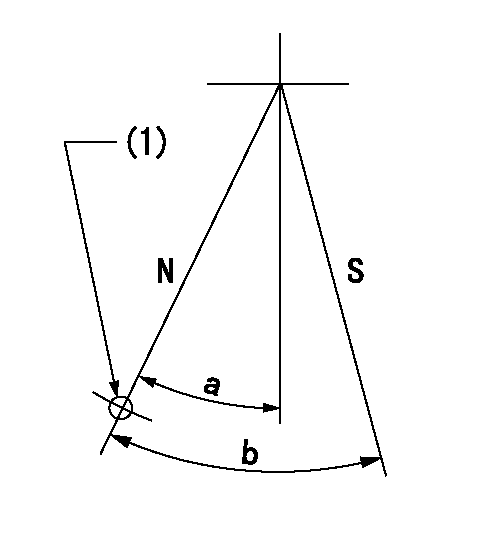

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

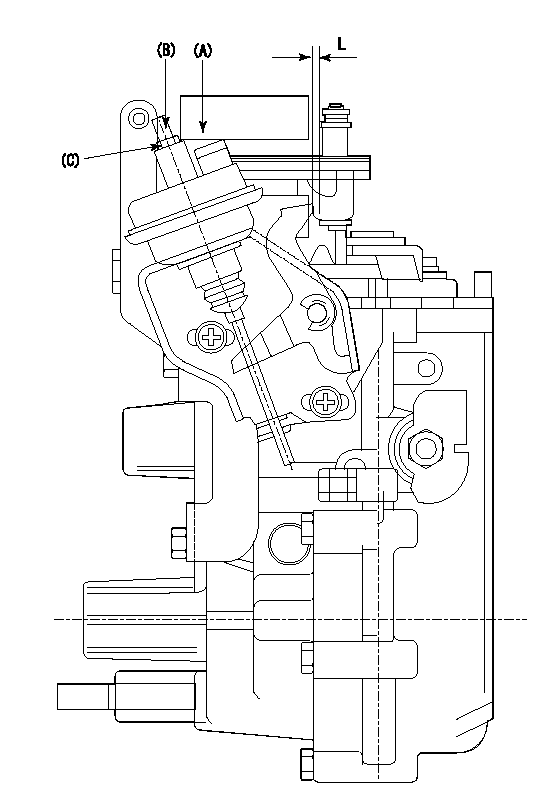

0000001501 FICD

(A) applied negative pressure

(B) Screw

(c) Nut

1. Set the actuator as described below.

(1)Confirm that there is clearance between the actuator lever and the speed lever.

(2)Loosen the nut (C).

(3)Push in the screw (B).

(4)Apply P1 from the actuator (A) part.

(5)Pull out the screw (B) slowly.

(6)Tighten and fix the nut (C) when pump speed is Na and the rack position is Ra.

(7)Torque the nut (C) to T1.

(8)Apply P2 several times.

(9)Confirm that the actuator functions normally.

(10)Confirm that there is a clearance between the actuator lever and the speed lever at that time.

----------

P1=53.3kPa(400mmHg) P2=53.3kPa(400mmHg) Na=425r/min Ra=9.1+-0.1mm T1=1.2~1.6N-m(0.12~0.16kgf-m)

----------

L=(5)mm

----------

P1=53.3kPa(400mmHg) P2=53.3kPa(400mmHg) Na=425r/min Ra=9.1+-0.1mm T1=1.2~1.6N-m(0.12~0.16kgf-m)

----------

L=(5)mm

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)Stamping position on the A/T outer rim

(4)At the No 1 cylinder's beginning of injection, align with the aligning mark seen through the bracket's check hole and mark the A/T's bevel C1.

(5)B.T.D.C.: aa

----------

aa=7deg

----------

a=(60deg) b=(85deg)

----------

aa=7deg

----------

a=(60deg) b=(85deg)

Information:

Lubrication System

OIL LUBRICATION SCHEMATICThe lubrication system is the pressure type. The oil pump draws oil from the sump through a suction pipe and strainer to the pump. The oil pump is driven by the auxiliary drive group which is driven by the timing gears.Pressure oil flows to the oil cooler. The oil cooler is cooled by water from the cooling system. Coolers on T6.3544 Engines have a bypass valve that allows the oil to go around the cooler in case of a restriction or if the oil is too cold and thick. From the cooler, oil passes through the relief valve. On T6.3544 Engines, the relief valve is two stage. At 205 to 225 kPa (30 to 37 psi), oil is fed by a pipe to the piston cooling jet gallery which is a drilled passage the length of the crankcase, above the camshaft chamber. The piston cooling jets are bolted into the gallery and point into the bottom of each cylinder. Oil is sprayed onto the underneath side of each piston which takes heat from the combustion area. The oil then drains back to sump.At 345 to 415 kPa (50 to 60 psi), oil passes through a single oil filter on 6.3544 Engines or two filters on T6.3544 Engines. Oil then flows to the main oil gallery which is a drilled passage the length of the crankcase. Oil also flows from the filters to the turbocharger bearings on T6.3544 Engines. Passages in the crankcase webs feed oil from the main oil gallery to the main bearings. Passages in the crankshaft carry oil to the big end bearings. Through passages in No. 1, 3, 5 and 7 crankcase webs, oil passes from the main bearings to lubricate the camshaft bearings.The No. 2 camshaft bearing supplies a controlled amount of oil to the rocker shaft assembly, which then flows through a small bleed hole in each rocker lever to lubricate the valves and springs.Pistons, cylinder liners, connecting rod small end bushings, cam lobes and valve lifters are splash and oil mist lubricated.Oil flows from the main oil gallery to the two idler gear hubs. The oil passes through the hubs to radial passages in the idler gears to lubricate the teeth of the timing gears.The auxiliary drive group shaft bearings are lubricated by a passage from the main oil gallery to the front auxiliary drive shaft bearing. Oil then passes around a groove in the bearing journal and through another passage along the outer side of the auxiliary drive housing to the rear auxiliary drive shaft bearing. The upper fuel pump bearing is also lubricated from this passage. Also connected to this outer housing passage is a spray tube which directs oil on to the auxiliary drive shaft (worn gear) and gear assembly (worm wheel).Air Inlet And Exhaust System

6.3544 Engines

AIR INLET AND EXHAUST SYSTEM COMPONENTS

1. Exhaust manifold. 2. Inlet manifold. 3. Engine cylinderThe air inlet and exhaust system components on naturally aspirated engines are: the air cleaner, inlet manifold,

OIL LUBRICATION SCHEMATICThe lubrication system is the pressure type. The oil pump draws oil from the sump through a suction pipe and strainer to the pump. The oil pump is driven by the auxiliary drive group which is driven by the timing gears.Pressure oil flows to the oil cooler. The oil cooler is cooled by water from the cooling system. Coolers on T6.3544 Engines have a bypass valve that allows the oil to go around the cooler in case of a restriction or if the oil is too cold and thick. From the cooler, oil passes through the relief valve. On T6.3544 Engines, the relief valve is two stage. At 205 to 225 kPa (30 to 37 psi), oil is fed by a pipe to the piston cooling jet gallery which is a drilled passage the length of the crankcase, above the camshaft chamber. The piston cooling jets are bolted into the gallery and point into the bottom of each cylinder. Oil is sprayed onto the underneath side of each piston which takes heat from the combustion area. The oil then drains back to sump.At 345 to 415 kPa (50 to 60 psi), oil passes through a single oil filter on 6.3544 Engines or two filters on T6.3544 Engines. Oil then flows to the main oil gallery which is a drilled passage the length of the crankcase. Oil also flows from the filters to the turbocharger bearings on T6.3544 Engines. Passages in the crankcase webs feed oil from the main oil gallery to the main bearings. Passages in the crankshaft carry oil to the big end bearings. Through passages in No. 1, 3, 5 and 7 crankcase webs, oil passes from the main bearings to lubricate the camshaft bearings.The No. 2 camshaft bearing supplies a controlled amount of oil to the rocker shaft assembly, which then flows through a small bleed hole in each rocker lever to lubricate the valves and springs.Pistons, cylinder liners, connecting rod small end bushings, cam lobes and valve lifters are splash and oil mist lubricated.Oil flows from the main oil gallery to the two idler gear hubs. The oil passes through the hubs to radial passages in the idler gears to lubricate the teeth of the timing gears.The auxiliary drive group shaft bearings are lubricated by a passage from the main oil gallery to the front auxiliary drive shaft bearing. Oil then passes around a groove in the bearing journal and through another passage along the outer side of the auxiliary drive housing to the rear auxiliary drive shaft bearing. The upper fuel pump bearing is also lubricated from this passage. Also connected to this outer housing passage is a spray tube which directs oil on to the auxiliary drive shaft (worn gear) and gear assembly (worm wheel).Air Inlet And Exhaust System

6.3544 Engines

AIR INLET AND EXHAUST SYSTEM COMPONENTS

1. Exhaust manifold. 2. Inlet manifold. 3. Engine cylinderThe air inlet and exhaust system components on naturally aspirated engines are: the air cleaner, inlet manifold,

Have questions with 101401-7295?

Group cross 101401-7295 ZEXEL

Isuzu

Nissan

Isuzu

Nissan

Isuzu

101401-7295

9 400 613 750

8971467781

INJECTION-PUMP ASSEMBLY

4HE1-T

4HE1-T