Information injection-pump assembly

BOSCH

F 01G 09U 00X

f01g09u00x

ZEXEL

101401-7293

1014017293

Rating:

Service parts 101401-7293 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-97115-503-1

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

14.

NOZZLE

Cross reference number

BOSCH

F 01G 09U 00X

f01g09u00x

ZEXEL

101401-7293

1014017293

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-3920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

3.8

3.75

3.85

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.1

Pump speed

r/min

1160

1160

1160

Average injection quantity

mm3/st.

97

95.4

98.6

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.7+-0.5

Pump speed

r/min

285

285

285

Average injection quantity

mm3/st.

14.5

13.2

15.8

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.1)

Pump speed

r/min

1160

1160

1160

Average injection quantity

mm3/st.

97

96

98

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

96.5

92.5

100.5

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2-0.45

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

86

82

90

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

95

95

127

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R2-0.45

Boost pressure

kPa

27.3

26

28.6

Boost pressure

mmHg

205

195

215

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

R2(R1-0.

6)

Boost pressure

kPa

46.7

46.7

46.7

Boost pressure

mmHg

350

350

350

Timer adjustment

Pump speed

r/min

1185--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1135

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1450

Advance angle

deg.

4.8

4.3

5.3

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

5

4.5

5.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

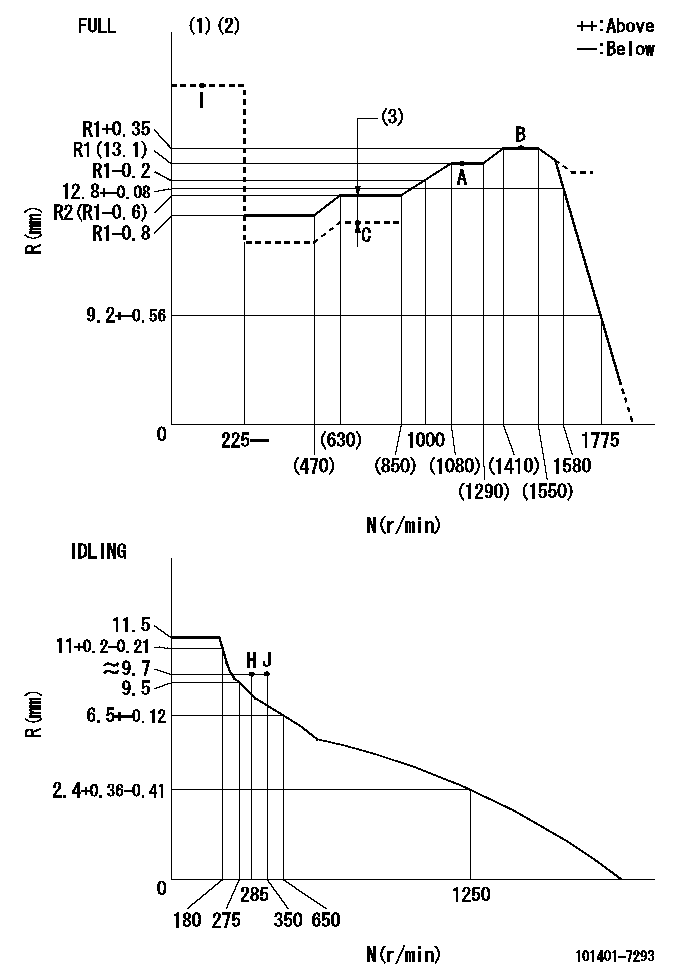

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=K06 BCL=0.45+-0.1mm

----------

----------

T1=K06 BCL=0.45+-0.1mm

----------

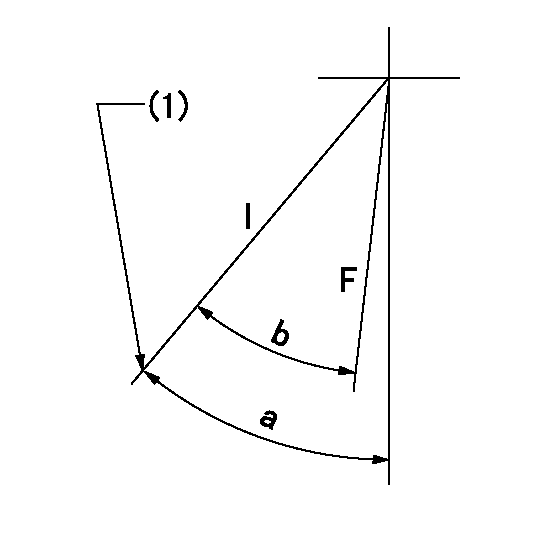

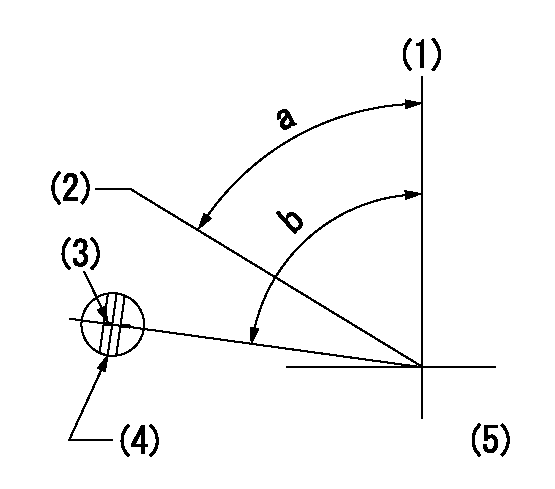

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=42deg+-5deg b=(41deg)+-3deg

----------

----------

a=42deg+-5deg b=(41deg)+-3deg

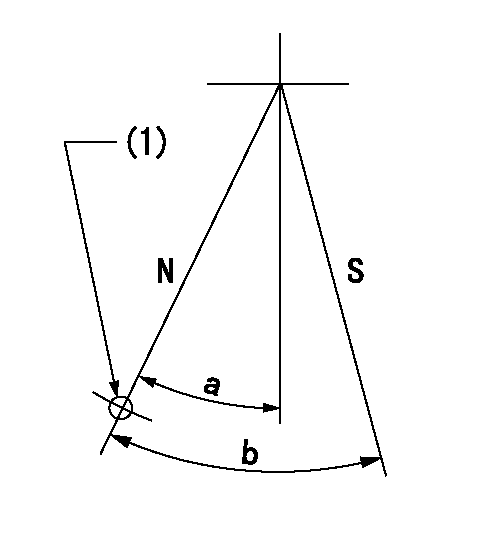

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

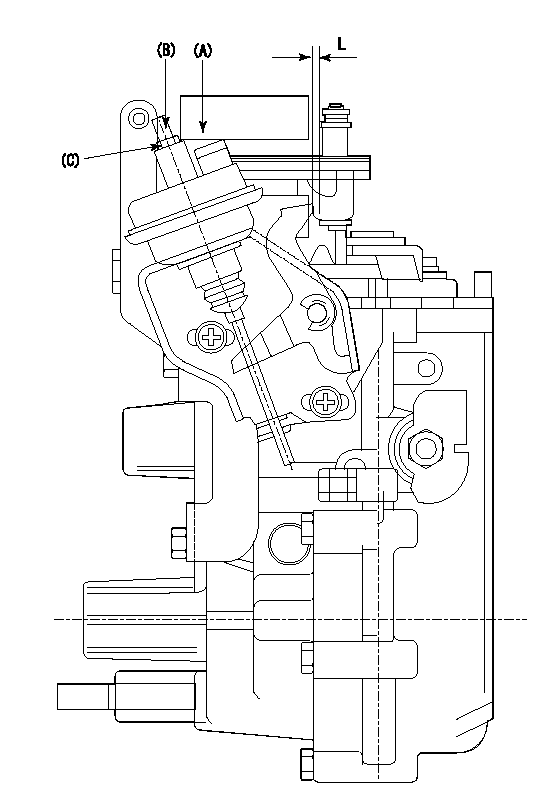

0000001501 FICD

(A) applied negative pressure

(B) Screw

(c) Nut

1. Set the actuator as described below.

(1)Confirm that there is clearance between the actuator lever and the speed lever.

(2)Loosen the nut (C).

(3)Push in the screw (B).

(4)Apply P1 from the actuator (A) part.

(5)Pull out the screw (B) slowly.

(6)Tighten and fix the nut (C) when pump speed is Na and the rack position is Ra.

(7)Torque the nut (C) to T1.

(8)Apply P2 several times.

(9)Confirm that the actuator functions normally.

(10)Confirm that there is a clearance between the actuator lever and the speed lever at that time.

----------

P1=53.3kPa(400mmHg) P2=53.3kPa(400mmHg) Na=410r/min Ra=9.75+-0.1mm T1=1.2~1.6N-m(0.12~0.16kgf-m)

----------

L=(5)mm

----------

P1=53.3kPa(400mmHg) P2=53.3kPa(400mmHg) Na=410r/min Ra=9.75+-0.1mm T1=1.2~1.6N-m(0.12~0.16kgf-m)

----------

L=(5)mm

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)Stamping position on the A/T outer rim

(4)At the No 1 cylinder's beginning of injection, align with the aligning mark seen through the bracket's check hole and mark the A/T's bevel C1.

(5)B.T.D.C.: aa

----------

aa=7deg

----------

a=(60deg) b=(85deg)

----------

aa=7deg

----------

a=(60deg) b=(85deg)

Information:

Lubrication System

Oil Lubrication Schematic

Oil Pump

(1) Strainer. (2) Oil Pump relief valve. (3) Oil pump. (4) Idler gear. (5) Crankshaft gear.The lubrication system is the pressure type and the flow of oil goes from the oil pan through strainer (1) into oil pump (3). Oil pump (3) is driven by crankshaft gear (5) through idler gear (4). The oil pump is connected to the front main bearing cap. Relief valve (2) which is spring loaded controls the maximum oil pressure. An oil pressure sending unit is connected to the main oil gallery.Oil under pressure goes from the oil pump through the relief valve and filter. On the T4.236 Engines, oil passes first through the oil cooler. The oil cooler is cooled by water from the cooling system. On engines that have a center mounted balancer unit, the oil pump and relief valve are integral with the balancer unit.Oil flows through the filter to the main oil gallery which is a drilled passage the length of the crankcase. A pipe from the filter head feeds oil to the turbocharger bearings on T4.236 Engines.From the gallery the oil flows through drilled passages to the main bearing bores and then through the crankshaft passages to the big end (rod) bearings. T4.236 Engine oil also flows from the main oil gallery to the piston cooling jets which have integral relief valves. The piston cooling jets feed oil to the underside of the pistons, where the oil circulates, taking heat from the combustion area. The cooling jets start operation at approximately 205 kPa (30 psi).

Timing Gears

(6) Idler gear. (7) Idler gear retainer plate.The crankshaft bearings are lubricated from numbers 1, 3 and 5 main bearings. The camshaft center bearing supplies a controlled amount of oil to the rocker shaft assembly. Oil from the rocker shaft drains through a bleed hole in each rocker lever to lubricate the valves and valve guides.Oil also goes from the gallery through the rear of idler gear (6) hub, then through passages to lubricate the idler gear bearing and gear retainer plate (7).Pistons, cylinder liners, connecting rod small end bushings, cam lobes and tappets (valve lifters) are splash and oil mist lubricated.Balancer Unit

Center Mounted Balancer Unit Components

(1) Idler gear hub. (2) Idler gear bearing. (3) Idler gear. (4) Idler gear thrust washer. (5) Balance weight bushings. (6) Balance weights. (7) Oil transfer cover plate. (8) Balancer frame. (9) Oil pump relief valve assembly. (10) Balance weights drive gear. (11) Gear shaft drive bearings. (12) Gear shaft drive. (13) Oil pump. (14) Oil suction pipe.Engines that are mounted stationary (rigid) have a balancer unit that is mounted to the block bottom face in the center of the engine. The balancer unit is timed to and driven by the crankshaft through a gear on the crankshaft and idler gear (3). The rotation of timed balance weights (10) counteracts the movement of the pistons and connecting rods of the engine.Oil pump (13) is part of and is driven by the balancer unit

Oil Lubrication Schematic

Oil Pump

(1) Strainer. (2) Oil Pump relief valve. (3) Oil pump. (4) Idler gear. (5) Crankshaft gear.The lubrication system is the pressure type and the flow of oil goes from the oil pan through strainer (1) into oil pump (3). Oil pump (3) is driven by crankshaft gear (5) through idler gear (4). The oil pump is connected to the front main bearing cap. Relief valve (2) which is spring loaded controls the maximum oil pressure. An oil pressure sending unit is connected to the main oil gallery.Oil under pressure goes from the oil pump through the relief valve and filter. On the T4.236 Engines, oil passes first through the oil cooler. The oil cooler is cooled by water from the cooling system. On engines that have a center mounted balancer unit, the oil pump and relief valve are integral with the balancer unit.Oil flows through the filter to the main oil gallery which is a drilled passage the length of the crankcase. A pipe from the filter head feeds oil to the turbocharger bearings on T4.236 Engines.From the gallery the oil flows through drilled passages to the main bearing bores and then through the crankshaft passages to the big end (rod) bearings. T4.236 Engine oil also flows from the main oil gallery to the piston cooling jets which have integral relief valves. The piston cooling jets feed oil to the underside of the pistons, where the oil circulates, taking heat from the combustion area. The cooling jets start operation at approximately 205 kPa (30 psi).

Timing Gears

(6) Idler gear. (7) Idler gear retainer plate.The crankshaft bearings are lubricated from numbers 1, 3 and 5 main bearings. The camshaft center bearing supplies a controlled amount of oil to the rocker shaft assembly. Oil from the rocker shaft drains through a bleed hole in each rocker lever to lubricate the valves and valve guides.Oil also goes from the gallery through the rear of idler gear (6) hub, then through passages to lubricate the idler gear bearing and gear retainer plate (7).Pistons, cylinder liners, connecting rod small end bushings, cam lobes and tappets (valve lifters) are splash and oil mist lubricated.Balancer Unit

Center Mounted Balancer Unit Components

(1) Idler gear hub. (2) Idler gear bearing. (3) Idler gear. (4) Idler gear thrust washer. (5) Balance weight bushings. (6) Balance weights. (7) Oil transfer cover plate. (8) Balancer frame. (9) Oil pump relief valve assembly. (10) Balance weights drive gear. (11) Gear shaft drive bearings. (12) Gear shaft drive. (13) Oil pump. (14) Oil suction pipe.Engines that are mounted stationary (rigid) have a balancer unit that is mounted to the block bottom face in the center of the engine. The balancer unit is timed to and driven by the crankshaft through a gear on the crankshaft and idler gear (3). The rotation of timed balance weights (10) counteracts the movement of the pistons and connecting rods of the engine.Oil pump (13) is part of and is driven by the balancer unit