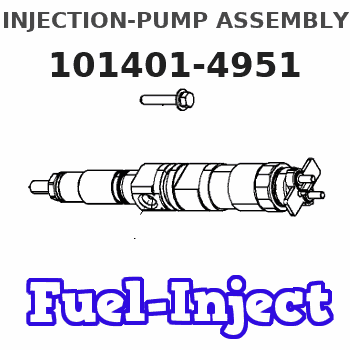

Information injection-pump assembly

BOSCH

9 400 610 401

9400610401

ZEXEL

101401-4951

1014014951

Rating:

Service parts 101401-4951 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-97115-503-1

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

14.

NOZZLE

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Inspect/Replace

Alternator and Fan Drive Belts

Inspect the condition and adjustment of alternator and accessory drive belts. Examine all drive belts for wear and replace if they show any signs of wear. Loose or worn pulley grooves cause belt slippage and low accessory drive speed. If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys and possibly slip enough to cause overheating.If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which might shorten the life of both.If one belt in a set requires replacement, always install a new matched set of belts. Never replace just the worn belt. If only the worn belt is replaced, the new belt will carry all the load, as it will not be stretched as much as the older belts. All the belts will fail in rapid succession.Adjust

1. Remove belt guard. Inspect the condition and adjustment of alternator belts and accessory drive belts, if equipped.2. To check the belt tension, apply 110 Newton (25 lb) force, perpendicular to the belt, midway between the driving and driven pulley. Measure the belt deflection. Correctly adjusted belts will deflect 15 to 20 mm (9/16 to 7/8 inch).If the belt does not require replacement or adjustment, install the belt guard. If the belt requires adjustment or replacement, do not install the belt guard. Perform the following procedure to adjust the belt tension.

(1) Typical belt assembly mounting bolt(2) adjusting nut3. Loosen the mounting bolt (1).4. Loosen the bracket adjusting nut(s) (2).5. Tighten or loosen the bracket adjusting nut(s) to obtain the correct adjustment.6. Tighten nuts (1) and (2).7. Check the belt tension. If the belt tension requires further adjustment, repeat steps 3 through 6.8. Install the belt guard.If new belts are installed, check the belt adjustment again after 30 minutes of engine operation.Hoses and Clamps

* Inspect all hoses for leaks due to cracking, softness and loose clamps. Replace hoses that are cracked or soft and tighten loose clamps.

Do not bend or strike high pressure lines. Do not install bent or damaged lines, tubes or hoses. Repair any loose or damaged fuel and oil lines, tubes and hoses. Leaks can cause fires. Inspect all lines, tubes and hoses carefully. Tighten all connections to the recommended torque.

Check for the following:* End fittings damaged, leaking or displaced.* Outer covering chafed or cut and wire reinforcing exposed.* Outer covering ballooning locally.* Evidence of kinking or crushing of the flexible part of the hose.* Armoring embedded in the outer cover.A constant torque hose clamp can be used in place of any standard hose clamp. Make sure the constant torque hose clamp is the same size as the standard clamp. Due to extreme temperature changes, hose will heat set. Heat setting causes hose clamps to loosen. Loose hose clamps can result in leaks. There have been reports of component failures caused by hose clamps loosening. The new, constant torque hose clamp will help prevent these failures.Each installation application can be different depending on

Alternator and Fan Drive Belts

Inspect the condition and adjustment of alternator and accessory drive belts. Examine all drive belts for wear and replace if they show any signs of wear. Loose or worn pulley grooves cause belt slippage and low accessory drive speed. If belts are too loose, they vibrate enough to cause unnecessary wear on the belts and pulleys and possibly slip enough to cause overheating.If belts are too tight, unnecessary stresses are placed upon the pulley bearings and belts which might shorten the life of both.If one belt in a set requires replacement, always install a new matched set of belts. Never replace just the worn belt. If only the worn belt is replaced, the new belt will carry all the load, as it will not be stretched as much as the older belts. All the belts will fail in rapid succession.Adjust

1. Remove belt guard. Inspect the condition and adjustment of alternator belts and accessory drive belts, if equipped.2. To check the belt tension, apply 110 Newton (25 lb) force, perpendicular to the belt, midway between the driving and driven pulley. Measure the belt deflection. Correctly adjusted belts will deflect 15 to 20 mm (9/16 to 7/8 inch).If the belt does not require replacement or adjustment, install the belt guard. If the belt requires adjustment or replacement, do not install the belt guard. Perform the following procedure to adjust the belt tension.

(1) Typical belt assembly mounting bolt(2) adjusting nut3. Loosen the mounting bolt (1).4. Loosen the bracket adjusting nut(s) (2).5. Tighten or loosen the bracket adjusting nut(s) to obtain the correct adjustment.6. Tighten nuts (1) and (2).7. Check the belt tension. If the belt tension requires further adjustment, repeat steps 3 through 6.8. Install the belt guard.If new belts are installed, check the belt adjustment again after 30 minutes of engine operation.Hoses and Clamps

* Inspect all hoses for leaks due to cracking, softness and loose clamps. Replace hoses that are cracked or soft and tighten loose clamps.

Do not bend or strike high pressure lines. Do not install bent or damaged lines, tubes or hoses. Repair any loose or damaged fuel and oil lines, tubes and hoses. Leaks can cause fires. Inspect all lines, tubes and hoses carefully. Tighten all connections to the recommended torque.

Check for the following:* End fittings damaged, leaking or displaced.* Outer covering chafed or cut and wire reinforcing exposed.* Outer covering ballooning locally.* Evidence of kinking or crushing of the flexible part of the hose.* Armoring embedded in the outer cover.A constant torque hose clamp can be used in place of any standard hose clamp. Make sure the constant torque hose clamp is the same size as the standard clamp. Due to extreme temperature changes, hose will heat set. Heat setting causes hose clamps to loosen. Loose hose clamps can result in leaks. There have been reports of component failures caused by hose clamps loosening. The new, constant torque hose clamp will help prevent these failures.Each installation application can be different depending on