Information injection-pump assembly

BOSCH

9 400 613 671

9400613671

ZEXEL

101401-4020

1014014020

ISUZU

8970188263

8970188263

Rating:

Service parts 101401-4020 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-94388-787-0

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 671

9400613671

ZEXEL

101401-4020

1014014020

ISUZU

8970188263

8970188263

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8210

Nozzle

105780-0070

Bosch type code

DN12SD12T-1

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

3.9

3.85

3.95

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.8

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

72.8

71.2

74.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.4

7.1

9.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.8)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

72.8

71.8

73.8

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.5

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

88.5

84.5

92.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

80

80

112

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1375--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1325

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1575

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

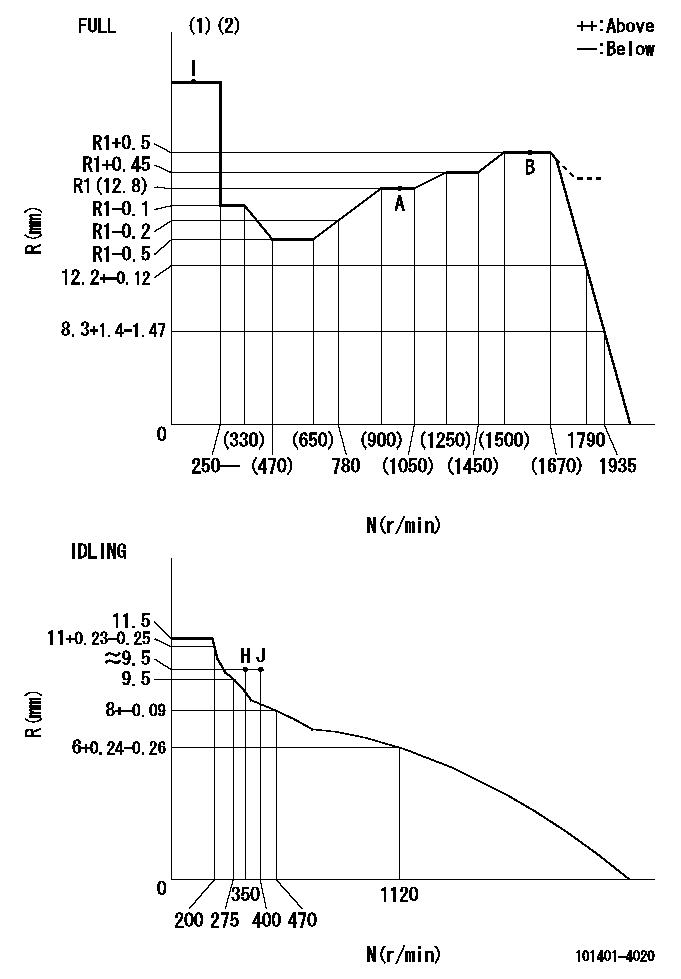

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=E87

----------

----------

T1=E87

----------

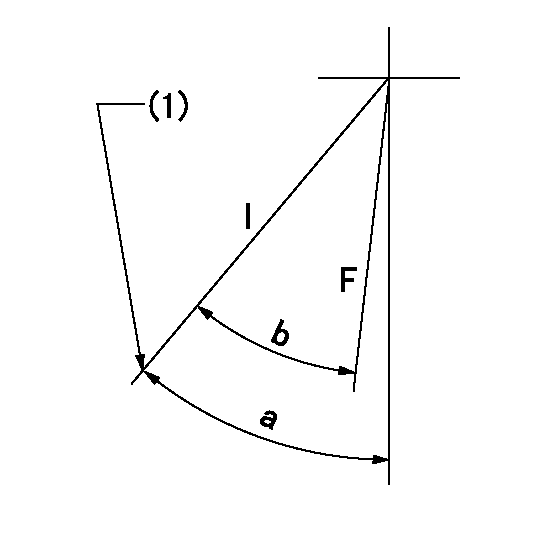

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=40deg+-5deg b=(34deg)+-3deg

----------

----------

a=40deg+-5deg b=(34deg)+-3deg

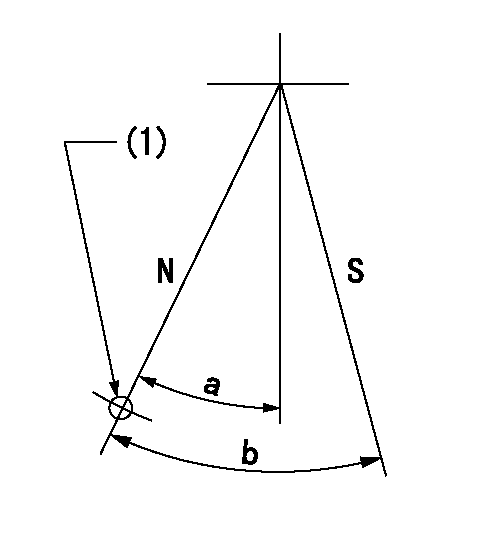

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

----------

aa=64mm

----------

a=20deg+-5deg b=29deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(60deg)

----------

aa=11deg

----------

a=(60deg)

Information:

September 13, 2003

(Revised October 2003)

U-250

A-177

D-181

O-210

beforeor

after failure PRODUCT SUPPORT PROGRAM FOR REPLACINGTHE INJECTION ACTUATION PRESSURE SENSOR ON CERTAIN 938G-II, 950G-II, 962G-IIWHEEL LOADERS AND IT62G-II, IT38G-II INTEGRATED TOOLCARRIERS

1925 PS41385

This Program can be administered eitherbefore or after failure. In either case the decision whether to apply theProgram is made by the dealer. When reporting the repair, use "PS41385"as the Part number and "7755" as the Group Number. If administered beforefailure, use "56" as the Warranty Claim Description Code and use "T" asthe SIMS Description Code. If administered after failure, use "96" as theWarranty Claim Description Code and use "Z" as the SIMS Description Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst. This Revised Service Letter replacesthe September 13, 2003 Service Letter. Changes have been made to the Titleand Affected Product.TERMINATION DATE

September 30, 2005PROBLEM

The injection actuation pressure sensor needsto be replaced on certain 938G-II, 950G-II, 962G-II Wheel Loaders and IT38G-IIIntegrated Toolcarriers. The 1946726 sensor may leak so it needs to bereplaced with the 2244536 sensor.AFFECTED PRODUCT

Model IdentificationNumber

938G II CRD1-435PHN1-549

950G II AXR1-243AXX1-386AYL1-1038AYB1-692AYD227-228AYS111-160BAA111-320

962G II AXY1-258AXS364-375AYE1-529AYG364-370BAB1-436BAC213-235BAD213-265

IT62G II AYA109-145

IT38G II CSX1-349PARTS NEEDED

Qty

Part Number Description

1 2244536 SENSOR GP-PRACTION REQUIRED

Remove 1946726 injection actuation pressure sensor.

Replace with 2244536 injection actuation pressuresensor.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs Parts Labor Hrs Parts Labor Hrs

0-4000 hrs

0-24 mos 100% 1.0 0 0 0 0

This is a 1.0?hr job.PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.

(Revised October 2003)

U-250

A-177

D-181

O-210

beforeor

after failure PRODUCT SUPPORT PROGRAM FOR REPLACINGTHE INJECTION ACTUATION PRESSURE SENSOR ON CERTAIN 938G-II, 950G-II, 962G-IIWHEEL LOADERS AND IT62G-II, IT38G-II INTEGRATED TOOLCARRIERS

1925 PS41385

This Program can be administered eitherbefore or after failure. In either case the decision whether to apply theProgram is made by the dealer. When reporting the repair, use "PS41385"as the Part number and "7755" as the Group Number. If administered beforefailure, use "56" as the Warranty Claim Description Code and use "T" asthe SIMS Description Code. If administered after failure, use "96" as theWarranty Claim Description Code and use "Z" as the SIMS Description Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst. This Revised Service Letter replacesthe September 13, 2003 Service Letter. Changes have been made to the Titleand Affected Product.TERMINATION DATE

September 30, 2005PROBLEM

The injection actuation pressure sensor needsto be replaced on certain 938G-II, 950G-II, 962G-II Wheel Loaders and IT38G-IIIntegrated Toolcarriers. The 1946726 sensor may leak so it needs to bereplaced with the 2244536 sensor.AFFECTED PRODUCT

Model IdentificationNumber

938G II CRD1-435PHN1-549

950G II AXR1-243AXX1-386AYL1-1038AYB1-692AYD227-228AYS111-160BAA111-320

962G II AXY1-258AXS364-375AYE1-529AYG364-370BAB1-436BAC213-235BAD213-265

IT62G II AYA109-145

IT38G II CSX1-349PARTS NEEDED

Qty

Part Number Description

1 2244536 SENSOR GP-PRACTION REQUIRED

Remove 1946726 injection actuation pressure sensor.

Replace with 2244536 injection actuation pressuresensor.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs Parts Labor Hrs Parts Labor Hrs

0-4000 hrs

0-24 mos 100% 1.0 0 0 0 0

This is a 1.0?hr job.PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.