Information injection-pump assembly

BOSCH

9 400 613 668

9400613668

ZEXEL

101401-3110

1014013110

KOMATSU

6354711310

6354711310

Rating:

Service parts 101401-3110 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

24.5{250}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 668

9400613668

ZEXEL

101401-3110

1014013110

KOMATSU

6354711310

6354711310

Zexel num

Bosch num

Firm num

Name

101401-3110

9 400 613 668

6354711310 KOMATSU

INJECTION-PUMP ASSEMBLY

4A95L K 14BD INJECTION PUMP ASSY PE4AD PE

4A95L K 14BD INJECTION PUMP ASSY PE4AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.2

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

131.5

129.9

133.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

56.3

54.3

58.3

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.2)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

131.5

130.5

132.5

Basic

*

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1280--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1230

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=784

----------

----------

T1=784

----------

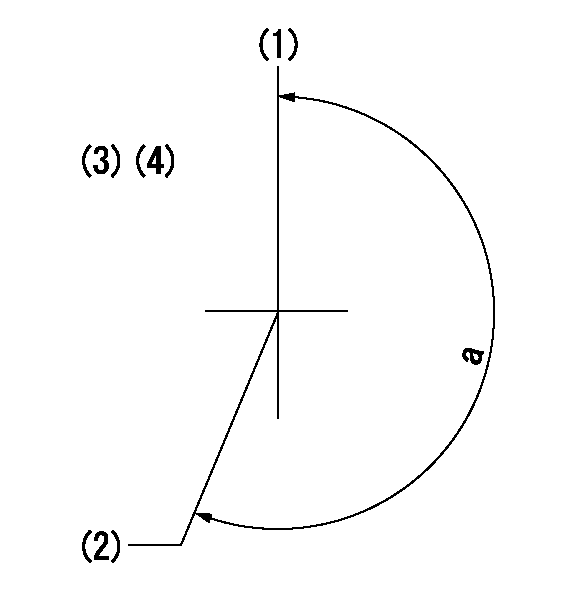

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=42.8mm

----------

a=40deg+-5deg b=(42deg)+-3deg

----------

aa=42.8mm

----------

a=40deg+-5deg b=(42deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=40deg+-5deg

----------

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(200deg)

----------

----------

a=(200deg)

Information:

Priority PRODUCTIMPROVEMENT PROGRAM FOR INSTALLING AN ADDITIONAL WATER SPRAY NOZZLE ONCERTAIN PM-465 COLD PLANERS

66095612 6635 PI30304

This Program must be administered assoon as possible. When reporting the repair, use "PI30304" as the Partnumber and "7751" as the Group Number, "56" as the Warranty Claim DescriptionCode and "T" as the SIMS Description Code. Exception: If the repair isdone after failure, use "PI30304" as the Part Number, "7751" as the GroupNumber, "96" as the Warranty Claim Description Code, and "Z" as the SIMSDescription Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.

COMPLETION DATE

TERMINATION DATE

November 30, 2002 May 31, 2003PROBLEM

An additional spray nozzle needs to be installedon certain PM-465 Cold Planers to provide a more even application of waterto the cutter teeth.AFFECTED PRODUCT

Model Identification Number

PM-465 5ZS139-182PARTS NEEDED

Dealers will need to order parts for this Program.

Quantity Part Number Description

2 5D1026 CLAMP-HOSE

1 1G6699 ADAPTER

1 1G8270 BODY-NOZZLE

100 5P1690 HOSE (100 CM)

1 812963 CAP

1 812965 SEAL

1 1159969 CONNECTOR-MA

1 1159970 CONNECTOR-MA

1 2118604 PLATE

1 2118607 TUBE

1 2120911 NOZZLEACTION REQUIRED

Refer to Special Instructions REHS1246 and installthe new spray nozzle and related parts.OWNER NOTIFICATION

U.S. and Canadian owners will receive the attachedOwner Notification.SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs. Parts Labor Hrs. Parts Labor Hrs.

100% 6 0 0 0 0

This is a 6-hour job.

U.S. and Canadian Dealers Only - Eligibledealers may enter a Type 2 SIMS Report.PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAMAS SOON AS POSSIBLE.Attach. (1-Owner Notification)COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999PRIORITY - PRODUCT IMPROVEMENT PROGRAM FORINSTALLING AN ADDITIONAL WATER SPRAY NOZZLE ON CERTAIN PM-465 COLD PLANERSMODELS INVOLVED - PM-465 COLD PLANERSDear Caterpillar Product Owner:An additional spray nozzle needs to be installedon the products listed below to provide a more even application of waterto the cutter teeth.Contact your local Caterpillar dealer immediatelyto schedule this service. The dealer will advise you of the time requiredto complete this service. Please refer the dealer to their Service Letterdated May 17, 2002 when scheduling this service. You will not be chargedfor the service performed.We regret the inconvenience this may causeyou, but urge you to have this service performed as soon as possible toprevent unscheduled downtime.Caterpillar Inc.Identification #(s)Attached to May 17, 2002 Service Letter

Have questions with 101401-3110?

Group cross 101401-3110 ZEXEL

Komatsu

101401-3110

9 400 613 668

6354711310

INJECTION-PUMP ASSEMBLY

4A95L

4A95L