Information injection-pump assembly

BOSCH

9 400 619 484

9400619484

ZEXEL

101401-2420

1014012420

HINO

220801870A

220801870a

Rating:

Service parts 101401-2420 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/21.6{220}

14.

NOZZLE

Cross reference number

BOSCH

9 400 619 484

9400619484

ZEXEL

101401-2420

1014012420

HINO

220801870A

220801870a

Zexel num

Bosch num

Firm num

Name

101401-2420

9 400 619 484

220801870A HINO

INJECTION-PUMP ASSEMBLY

W04D-TI K 14BL INJECTION PUMP ASSY PE 5MD PE

W04D-TI K 14BL INJECTION PUMP ASSY PE 5MD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8310

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2240

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED4 control unit part number

407915-0

590

RED4 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.45

3.42

3.48

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Rack position

(11.9)

PWM

%

55.3

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

71

70

72

Max. variation between cylinders

%

0

-3

3

Basic

*

Injection quantity adjustment_02

Rack position

(7)

PWM

%

27.7+-2.

8

Pump speed

r/min

370

370

370

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Governor adjustment

Pump speed

r/min

1300--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

1250

Advance angle

deg.

0.3

Governor adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

1.5

1.2

1.8

Governor adjustment_04

Pump speed

r/min

-

Advance angle

deg.

3

3

3

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

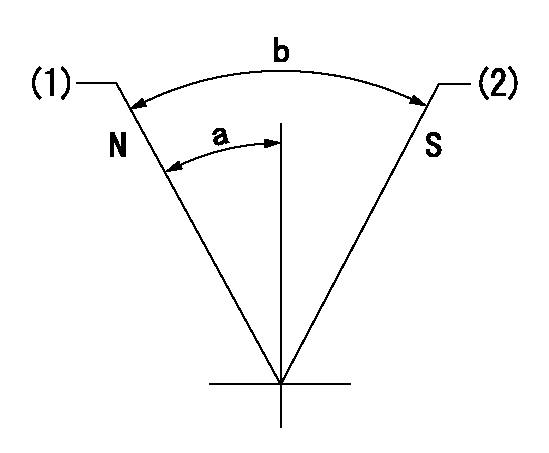

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=0deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=0deg+-5deg b=37deg+-5deg

0000000901

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Stop lever angle

(PWM) Pulse width modulation (%)

(R) Rack position (mm)

Rack sensor output characteristics

1. Rack limit adjustment

(1)Measure the rack position R2 for PWM a2%.

(2)Confirm that it is within the range R2 = 15+-1 mm.

(3)Measure the rack position R1 at PWM a %.

(4)Confirm that it is within the range R2 - R1 = 10+-0.1 mm.

2. Check the limp home operation.

(1)Move the switch box's limp home switch to the limp home side.

(2)Confirm rack position L1 (mm ) and L2 (mm) for PWM in the above table.

3. Check the pull down operation.

(1)Confirm that the rack position is 19 mm at PWM B%.

(2)In the conditions described in the above table, move the switch box's pull down switch to the pull down side and confirm that the rack position momentarily becomes 1 mm or less.

----------

a1=16.25% a2=72.5% L1=1--mm L2=19++mm A=5 % B=95%

----------

----------

a1=16.25% a2=72.5% L1=1--mm L2=19++mm A=5 % B=95%

----------

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

Termination Date

March 31, 1997Problem

Improvements have been made to the remanufactured unit injectors that are used in various 3114 and 3116 Engines. All of the former 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors need to be removed from Parts Stock.

Action Required

Remove all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors from Parts Stock.

When ordering parts, refer to the attached chart until the information is available in a permanent publication.

Service Claim Allowances

Submit one claim for all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors removed from Parts Stock.

TEPS Dealers should refer to their warranty bullitin for proper claiming and disposition.

Parts Disposition

All injectors removed from Parts Stock are to be returned as cores for remanufacturing.

U.S. and Canadian Dealers

Return all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn: Bill Harland - Warranty Review

501 Cardinal Drive

Corinth, MS 38834

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on Remanufactured Engines and Components, refer to the topic "Disposition of the Core Under Warranty".

Attach.(1-UNIT INJECTOR CHART)3114 & 3116 Unit Injector Chart

Termination Date

March 31, 1997Problem

Improvements have been made to the remanufactured unit injectors that are used in various 3114 and 3116 Engines. All of the former 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors need to be removed from Parts Stock.

Action Required

Remove all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors from Parts Stock.

When ordering parts, refer to the attached chart until the information is available in a permanent publication.

Service Claim Allowances

Submit one claim for all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors removed from Parts Stock.

TEPS Dealers should refer to their warranty bullitin for proper claiming and disposition.

Parts Disposition

All injectors removed from Parts Stock are to be returned as cores for remanufacturing.

U.S. and Canadian Dealers

Return all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn: Bill Harland - Warranty Review

501 Cardinal Drive

Corinth, MS 38834

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on Remanufactured Engines and Components, refer to the topic "Disposition of the Core Under Warranty".

Attach.(1-UNIT INJECTOR CHART)3114 & 3116 Unit Injector Chart

Have questions with 101401-2420?

Group cross 101401-2420 ZEXEL

Hino

101401-2420

9 400 619 484

220801870A

INJECTION-PUMP ASSEMBLY

W04D-TI

W04D-TI