Information injection-pump assembly

BOSCH

9 400 612 405

9400612405

ZEXEL

101401-2400

1014012400

HINO

220402170A

220402170a

Rating:

Service parts 101401-2400 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-3490A

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/21.6{220}

14.

NOZZLE

Cross reference number

BOSCH

9 400 612 405

9400612405

ZEXEL

101401-2400

1014012400

HINO

220402170A

220402170a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8310

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2240

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

-

Rack position

12.8

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

53.5

51.5

55.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

13

11.5

14.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.8)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

53.5

52.5

54.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

73.3

73.3

Boost pressure

mmHg

550

550

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.2

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

59

55

63

Fixing the lever

*

Boost pressure

kPa

73.3

73.3

Boost pressure

mmHg

550

550

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R2-0.85

Boost pressure

kPa

42.7

41.4

44

Boost pressure

mmHg

320

310

330

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

R2(R1-0.

6)

Boost pressure

kPa

60

60

60

Boost pressure

mmHg

450

450

450

Timer adjustment

Pump speed

r/min

1350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

2.5

2.2

2.8

Remarks

Finish

Finish

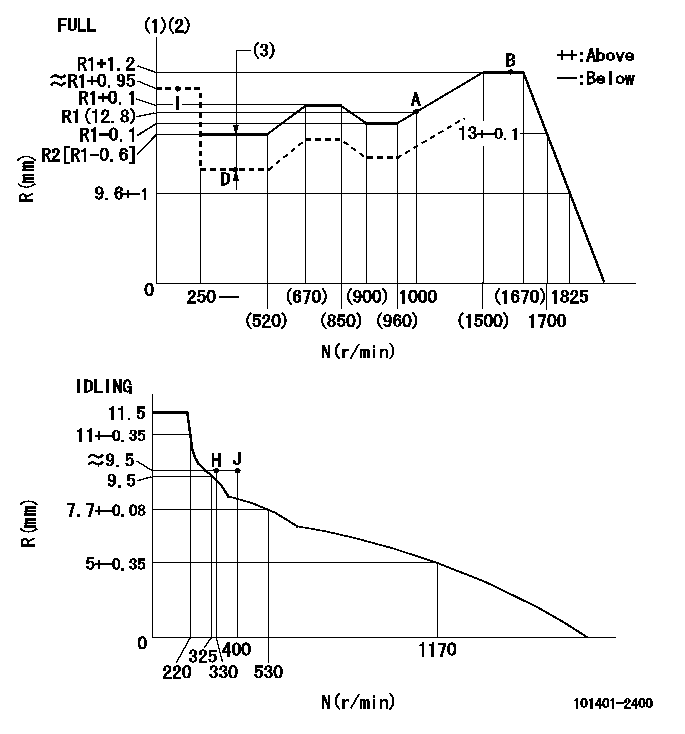

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=P27 BCL=0.85+-0.1mm

----------

----------

T1=P27 BCL=0.85+-0.1mm

----------

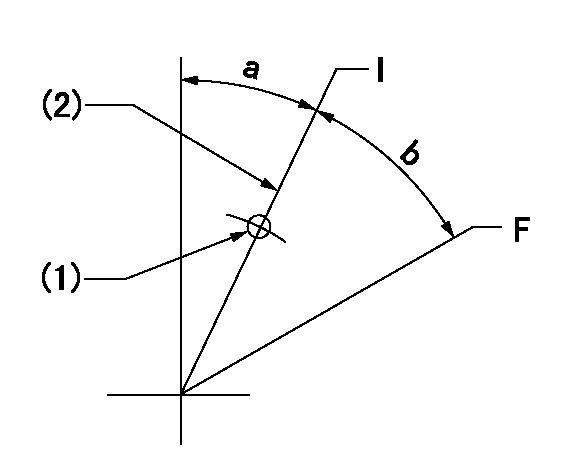

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=50mm

----------

a=22.5deg+-5deg b=40deg+-3deg

----------

aa=50mm

----------

a=22.5deg+-5deg b=40deg+-3deg

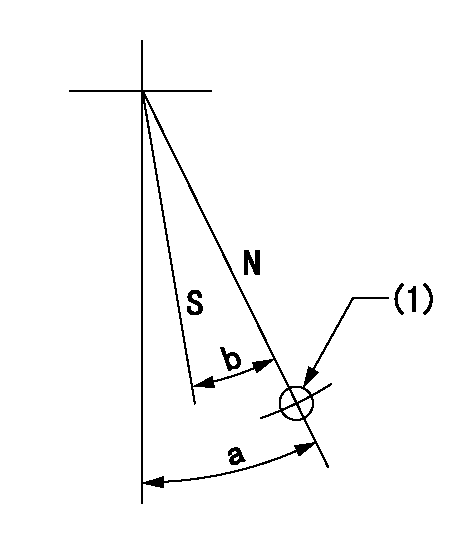

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=40mm

----------

a=40deg+-5deg b=40deg+-5deg

----------

aa=40mm

----------

a=40deg+-5deg b=40deg+-5deg

0000001501 AIR CYLINDER

(A): Speed lever

(B): Set bolt

(C): air cylinder

(D): nut

(E): fix

1. Air cylinder adjustment procedure

(1)With the speed lever in the idling position, temporarily set the clearance between speed lever (A) and set bolt (B) at approximately L1.

(2)Set the speed to N1 and supply positive pressure P1 to the air cylinder (C).

(3)Gradually push set bolt (B) out (approximately L2) and tighten nut (D) where the speed is N2 and the rack position is Ra.

(4)Apply positive pressure P1 several times.

(5)Confirm that the lever returns to the idle position at positive pressure P2.

(6)Also, confirm that the rack position is Rb at air pressure P1.

----------

L1=9mm L2=6.5mm Ra=10.65-0.2mm Rb=10.65-0.2mm N1=330r/min N2=330r/min P1=392+98kPa(4+1kgf/cm2) P2=0kPa(0kgf/cm2)

----------

----------

L1=9mm L2=6.5mm Ra=10.65-0.2mm Rb=10.65-0.2mm N1=330r/min N2=330r/min P1=392+98kPa(4+1kgf/cm2) P2=0kPa(0kgf/cm2)

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS8088" as the Part Number and "7755" as the Group Number. If administered before failure, use "56" as the Warranty Claim Description Code and use "T" as the SIMS Description Code. If administered after failure, use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

This Revised Service Letter replaces the January 25, 1994 (Revised December 1994) Service Letter. Changes have been made to the Parts Stock Action.

Termination Date

January 31, 1996Problem

The fuel nozzles used on certain 3208 Engines may crack at the braze joint.

Affected Product

Model & Identification Number

3208 ( 30A5540-5956 (Arrangements 9Y8574, 9Y8575, 1228675, 1228676, 1228679, 1228680); 62W74820-80012 (Arrangements 0R0776, 0R0975, 0R0976, 0R2818, 0R2819, 0R2875, 0R3231); 5YF1531-2058 (Arrangements 4P2649, 4P3027, 9Y2229, 9Y3136, 1042666, 1061496, 1077956, 1077957); 01Z26425-28100 (Arrangements 2W1320, 2W1325, 7W7500, 7W9150, 1013714, 1176582); 03Z11912-13004 (Arrangements 4P1724, 1067075, 1108885, 1168163, 1168164, 1168165, 1214692); 51Z81870-82239 (Arrangements 4P0921, 4P0922, 111364); 93Z8798-11332 (Arrangement 0R1098); 99R1533-1541 (Arrangement 5R6639); 79V24858 (Arrangement 1W0331))

Parts Needed

1 - 0R2503 Nozzle Assembly (Reman Equivalent of 1W5829)*1 - 0R2821 Nozzle Assembly (Reman Equivalent of 7W3710)*1 - 0R3284 Nozzle Assembly (Reman Equivalent of 4W8483)*1 - 1153354 Nozzle Assembly (No Reman Equivalent)**Use as requiredAction Required

Parts Stock

Remove all 0R2503, 0R2821, 0R3284, 1W5829, 4W8483, 7W3710, and 1153354 Nozzle Assemblies from Parts Stock with date codes of D--3, E--3, F--3, G--3, H--3, J--3, K--3, L--3, M--3, A--4, B--4, C--4, D--4, E--4, or F--4. Date codes are located on the nozzle assembly as shown below:

Location of Date CodeAffected Product

Remove all 0R2503, 0R2821, 0R3284, 1W5829, 4W8483, 7W3710, and 1153354 Nozzle Assemblies with date codes of D--3, E--3, F--3, G--3, H--3, J--3, K--3, L--3, M--3, A--4, B--4, C--4, D--4, E--4, or F--4 from the engine and replace with new nozzle assemblies or the remanufactured equivalent nozzle assemblies.

Service Claim Allowances

Parts Stock

US and Canadian Dealers Only - When submitting a Parts Stock claim use 99Z00007 in the Product Identification Number Field.

Affected Product

Industrial and Marine Engines Up to 6-hours labor may be claimed.

Truck Engines Claim labor hours in accordance with TRG book.

Parts Disposition

U.S. and Canadian Dealers

Return all 0R2503, 0R2821, 0R3284, 1W5829, 4W8483, 7W3710, and 1153354 Nozzle Assemblies that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn:Howard Jenkel

Service Claims Room

8201 N. University

Peoria, IL 61615

For remanufactured nozzle assemblies 0R2503, 0R2821, and 0R3284, include a copy of the "Core Credit Request Packing List".

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS8088" as the Part Number and "7755" as the Group Number. If administered before failure, use "56" as the Warranty Claim Description Code and use "T" as the SIMS Description Code. If administered after failure, use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

This Revised Service Letter replaces the January 25, 1994 (Revised December 1994) Service Letter. Changes have been made to the Parts Stock Action.

Termination Date

January 31, 1996Problem

The fuel nozzles used on certain 3208 Engines may crack at the braze joint.

Affected Product

Model & Identification Number

3208 ( 30A5540-5956 (Arrangements 9Y8574, 9Y8575, 1228675, 1228676, 1228679, 1228680); 62W74820-80012 (Arrangements 0R0776, 0R0975, 0R0976, 0R2818, 0R2819, 0R2875, 0R3231); 5YF1531-2058 (Arrangements 4P2649, 4P3027, 9Y2229, 9Y3136, 1042666, 1061496, 1077956, 1077957); 01Z26425-28100 (Arrangements 2W1320, 2W1325, 7W7500, 7W9150, 1013714, 1176582); 03Z11912-13004 (Arrangements 4P1724, 1067075, 1108885, 1168163, 1168164, 1168165, 1214692); 51Z81870-82239 (Arrangements 4P0921, 4P0922, 111364); 93Z8798-11332 (Arrangement 0R1098); 99R1533-1541 (Arrangement 5R6639); 79V24858 (Arrangement 1W0331))

Parts Needed

1 - 0R2503 Nozzle Assembly (Reman Equivalent of 1W5829)*1 - 0R2821 Nozzle Assembly (Reman Equivalent of 7W3710)*1 - 0R3284 Nozzle Assembly (Reman Equivalent of 4W8483)*1 - 1153354 Nozzle Assembly (No Reman Equivalent)**Use as requiredAction Required

Parts Stock

Remove all 0R2503, 0R2821, 0R3284, 1W5829, 4W8483, 7W3710, and 1153354 Nozzle Assemblies from Parts Stock with date codes of D--3, E--3, F--3, G--3, H--3, J--3, K--3, L--3, M--3, A--4, B--4, C--4, D--4, E--4, or F--4. Date codes are located on the nozzle assembly as shown below:

Location of Date CodeAffected Product

Remove all 0R2503, 0R2821, 0R3284, 1W5829, 4W8483, 7W3710, and 1153354 Nozzle Assemblies with date codes of D--3, E--3, F--3, G--3, H--3, J--3, K--3, L--3, M--3, A--4, B--4, C--4, D--4, E--4, or F--4 from the engine and replace with new nozzle assemblies or the remanufactured equivalent nozzle assemblies.

Service Claim Allowances

Parts Stock

US and Canadian Dealers Only - When submitting a Parts Stock claim use 99Z00007 in the Product Identification Number Field.

Affected Product

Industrial and Marine Engines Up to 6-hours labor may be claimed.

Truck Engines Claim labor hours in accordance with TRG book.

Parts Disposition

U.S. and Canadian Dealers

Return all 0R2503, 0R2821, 0R3284, 1W5829, 4W8483, 7W3710, and 1153354 Nozzle Assemblies that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn:Howard Jenkel

Service Claims Room

8201 N. University

Peoria, IL 61615

For remanufactured nozzle assemblies 0R2503, 0R2821, and 0R3284, include a copy of the "Core Credit Request Packing List".

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.