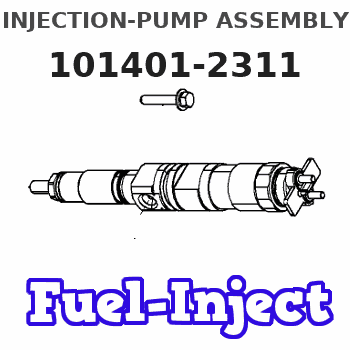

Information injection-pump assembly

ZEXEL

101401-2311

1014012311

HINO

220204500B

220204500b

Rating:

Service parts 101401-2311 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2601A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Fuel Specifications

Types of Fuel

Caterpillar diesel engines have the ability to burn a wide variety of fuels. These fuels are divided into two general groups, preferred and permissible.The preferred fuels provide maximum engine service life and performance. They are distillate fuels. They are commonly called fuel oil, furnace oil, diesel fuel, gas oil or kerosene.The permissible fuels are crude oils or blended fuels. Use of these fuels can result in higher maintenance costs and reduced engine service life.Refer to Fuels for Caterpillar Diesel Engines, Form SEHS7067, for a detailed summary of preferred and permissible fuels and their specifications.Cetane Requirement

The minimum fuel cetane number recommended for the engine is 40.Fuel Cloud Point

Fuel waxing can plug the fuel filters in cold weather. The fuel cloud point must be below the temperature of the surrounding air to prevent filter waxing and power loss. Fuel heating attachments are available from your Caterpillar dealer to minimize fuel filter waxing.Fuel Sulfur Content

The percentage of sulfur in the fuel will affect the engine oil recommendations. If the fuel has over 0.5% sulfur content, the CD engine oil must have a TBN of 20 times the percentage of fuel sulfur (TBN as measured by the ASTM D-2896 method). Your oil supplier should be able to furnish the correct oils.Coolant Specifications

Always use coolant conditioner elements. Never use plain water only.Do not use Caterpillar coolant system conditioner elements with Dowtherm 209 Full-Fill coolant. Follow the instructions provided with the Dowtherm 209 Full-Fill coolant.

Use a mixture of fill water and antifreeze, and a coolant conditioner element.Know Your Cooling System, Form SEBD0518, provides more detailed specifications.Fill Water

Acceptable water for use in the ethylene glycol-type antifreeze and water mixture is shown on the chart below: Antifreeze

Use ethylene glycol-type antifreeze. Use the correct amount to provide freeze protection to the lowest expected outside temperature.Coolant Conditioner Elements

Coolant conditioner elements should be used to maintain a 3% to 6% concentration of conditioner in the coolant. Use a precharge element when filling the complete system, or changing coolant. Install a new maintenance element every 250 service hours during operation. Contact your Caterpillar dealer for the correct coolant conditioner element.Lubricant Specifications

The abbreviations listed below follow S.A.E. J754 nomenclature. The classifications follow S.A.E. J183 classifications. The MIL specifications are U.S.A. Military Specifications. These definitions will be of assistance in purchasing lubricants. The recommended oil viscosities for this machine are found on the "Recommended Lubricant Viscosities" Chart.Engine Oils (CD)

Use oils that meet Engine Service Classification CD (MIL-L-2104C).Consult the EMA Lubricating Oil Data Book, Form SEBU5939, for a listing of CD oil brands.The percentage of sulfur in the fuel will affect the engine oil recommendations. If the fuel has over 0.5% sulfur content, the CD engine oil must have a TBN of 20 times the percentage of fuel sulfur (TBN as measured by the ASTM D-2896 method). Your oil supplier should be able to furnish the correct oils.

Types of Fuel

Caterpillar diesel engines have the ability to burn a wide variety of fuels. These fuels are divided into two general groups, preferred and permissible.The preferred fuels provide maximum engine service life and performance. They are distillate fuels. They are commonly called fuel oil, furnace oil, diesel fuel, gas oil or kerosene.The permissible fuels are crude oils or blended fuels. Use of these fuels can result in higher maintenance costs and reduced engine service life.Refer to Fuels for Caterpillar Diesel Engines, Form SEHS7067, for a detailed summary of preferred and permissible fuels and their specifications.Cetane Requirement

The minimum fuel cetane number recommended for the engine is 40.Fuel Cloud Point

Fuel waxing can plug the fuel filters in cold weather. The fuel cloud point must be below the temperature of the surrounding air to prevent filter waxing and power loss. Fuel heating attachments are available from your Caterpillar dealer to minimize fuel filter waxing.Fuel Sulfur Content

The percentage of sulfur in the fuel will affect the engine oil recommendations. If the fuel has over 0.5% sulfur content, the CD engine oil must have a TBN of 20 times the percentage of fuel sulfur (TBN as measured by the ASTM D-2896 method). Your oil supplier should be able to furnish the correct oils.Coolant Specifications

Always use coolant conditioner elements. Never use plain water only.Do not use Caterpillar coolant system conditioner elements with Dowtherm 209 Full-Fill coolant. Follow the instructions provided with the Dowtherm 209 Full-Fill coolant.

Use a mixture of fill water and antifreeze, and a coolant conditioner element.Know Your Cooling System, Form SEBD0518, provides more detailed specifications.Fill Water

Acceptable water for use in the ethylene glycol-type antifreeze and water mixture is shown on the chart below: Antifreeze

Use ethylene glycol-type antifreeze. Use the correct amount to provide freeze protection to the lowest expected outside temperature.Coolant Conditioner Elements

Coolant conditioner elements should be used to maintain a 3% to 6% concentration of conditioner in the coolant. Use a precharge element when filling the complete system, or changing coolant. Install a new maintenance element every 250 service hours during operation. Contact your Caterpillar dealer for the correct coolant conditioner element.Lubricant Specifications

The abbreviations listed below follow S.A.E. J754 nomenclature. The classifications follow S.A.E. J183 classifications. The MIL specifications are U.S.A. Military Specifications. These definitions will be of assistance in purchasing lubricants. The recommended oil viscosities for this machine are found on the "Recommended Lubricant Viscosities" Chart.Engine Oils (CD)

Use oils that meet Engine Service Classification CD (MIL-L-2104C).Consult the EMA Lubricating Oil Data Book, Form SEBU5939, for a listing of CD oil brands.The percentage of sulfur in the fuel will affect the engine oil recommendations. If the fuel has over 0.5% sulfur content, the CD engine oil must have a TBN of 20 times the percentage of fuel sulfur (TBN as measured by the ASTM D-2896 method). Your oil supplier should be able to furnish the correct oils.