Information injection-pump assembly

ZEXEL

101401-2310

1014012310

Rating:

Service parts 101401-2310 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2601A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

ZEXEL

101401-2310

1014012310

Zexel num

Bosch num

Firm num

Name

101401-2310

INJECTION-PUMP ASSEMBLY

14BC PE4A,5A, PE

14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.17

3.23

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

A

Rack position

12.8

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

115

113

117

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

78.6

78.6

Boost pressure

mmHg

590

590

Injection quantity adjustment_02

Adjusting point

C

Rack position

9+-0.5

Pump speed

r/min

405

405

405

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

900

900

900

Rack position

R1-1.85

Boost pressure

kPa

16

13.3

18.7

Boost pressure

mmHg

120

100

140

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Rack position

R1(12.8)

Boost pressure

kPa

65.3

58.6

72

Boost pressure

mmHg

490

440

540

Timer adjustment

Pump speed

r/min

1275--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1225

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

1450

Advance angle

deg.

3.25

2.95

3.55

Load

4/4

Remarks

Finish

Finish

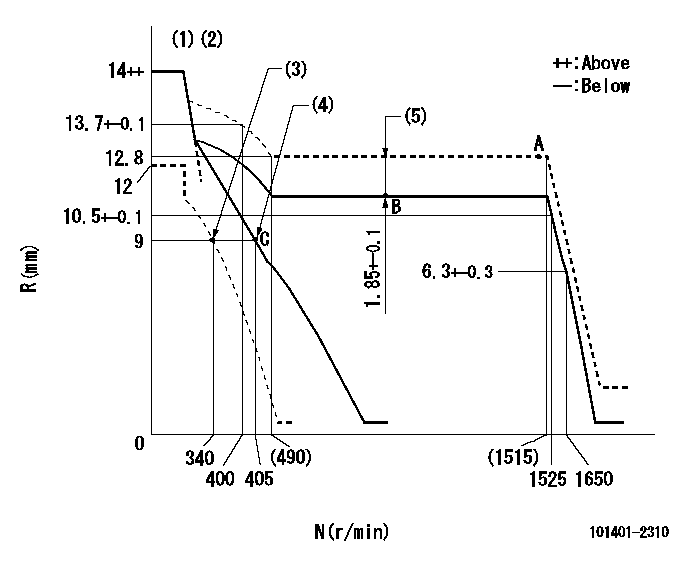

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerances for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

(4)Main spring setting

(5)Boost compensator stroke

----------

K=10

----------

----------

K=10

----------

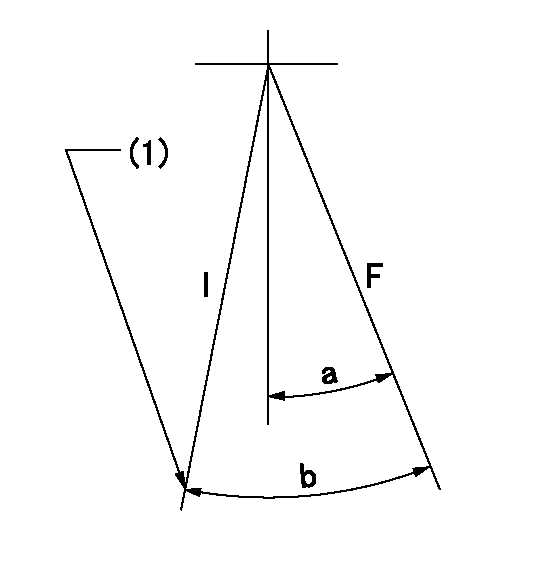

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=26deg+-5deg

----------

----------

a=10deg+-5deg b=26deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Cooling System

Never add coolant to an overheated engine; allow the engine to cool first.Check the specific gravity of the antifreeze coolant solution frequently in cold weather to ensure adequate protection.If the machine is to be stored in, or shipped to, an area with below freezing temperatures; the cooling system must be protected against freezing to the lowest expected outside temperature.All water is corrosive at engine operating temperature. The cooling system should be protected with conditioner at all times regardless of the concentration of antifreeze. This can be done by using Caterpillar coolant conditioner elements. Use a precharge element when filling the system or changing coolant. Install a new maintenance element every 250 service hours during operation.Do not use Caterpillar coolant conditioner elements with Dowtherm 209 Full-Fill coolant. Follow the instructions provided with the Dowtherm 209 Full-Fill coolant.

Coolant should be drained and replaced every 2000 service hours or 1 year. However, when coolant conditioner maintenance elements are replaced every 250 service hours as recommended, the drain period can be extended to 4000 service hours or 2 years. If your engine does not use coolant conditioner elements, see "Cooling System" under "Maintenance Recommendations" in your Maintenance (Lubrication and Maintenance) Guide.Premix antifreeze coolant solution to provide protection to the lowest expected outside temperature. Pure undiluted antifreeze will freeze at -23°C (-10°F).Use clean water that is low in scale forming mineral. Do not use softened water.Filling at over 20 liters (5 U.S. gallons) per minute can cause air pockets in the cooling system.After draining and refilling the cooling system, start and operate the engine with the fill cap off until the coolant level stabilizes. Add coolant as necessary to fill the system.When the engine is shipped from the factory, its cooling system is protected to -28°C (-20°F), with permanent-type antifreeze.Operate with a thermostat in the cooling system year-round. Overheating can arise without a thermostat.Fuel System

Fill the fuel tank at the end of each day of operation to drive out moist air and to prevent condensation. Do not fill the tank to the top. The fuel expands as it gets warm and may overflow.

Do not fill the fuel filters with fuel before installing them. Contaminated fuel will cause accelerated wear to the fuel system parts.

Check the fuel level with the dipstick in the filler opening. Drain the water and sediment from the fuel tank at the start of a shift or after the fuel tank has been filled and allowed to stand for 5 to 10 minutes.After changing the fuel filters, always bleed the fuel system to remove air bubbles from the system.Drain water and sediment from any fuel storage tank weekly, and before the tank is refilled. This will help prevent water or sediment from being pumped from the storage tank into the machine fuel tank.Use only fuel as recommended in the 'Fuel, Coolant and Lubricant" section of this Guide.

Never add coolant to an overheated engine; allow the engine to cool first.Check the specific gravity of the antifreeze coolant solution frequently in cold weather to ensure adequate protection.If the machine is to be stored in, or shipped to, an area with below freezing temperatures; the cooling system must be protected against freezing to the lowest expected outside temperature.All water is corrosive at engine operating temperature. The cooling system should be protected with conditioner at all times regardless of the concentration of antifreeze. This can be done by using Caterpillar coolant conditioner elements. Use a precharge element when filling the system or changing coolant. Install a new maintenance element every 250 service hours during operation.Do not use Caterpillar coolant conditioner elements with Dowtherm 209 Full-Fill coolant. Follow the instructions provided with the Dowtherm 209 Full-Fill coolant.

Coolant should be drained and replaced every 2000 service hours or 1 year. However, when coolant conditioner maintenance elements are replaced every 250 service hours as recommended, the drain period can be extended to 4000 service hours or 2 years. If your engine does not use coolant conditioner elements, see "Cooling System" under "Maintenance Recommendations" in your Maintenance (Lubrication and Maintenance) Guide.Premix antifreeze coolant solution to provide protection to the lowest expected outside temperature. Pure undiluted antifreeze will freeze at -23°C (-10°F).Use clean water that is low in scale forming mineral. Do not use softened water.Filling at over 20 liters (5 U.S. gallons) per minute can cause air pockets in the cooling system.After draining and refilling the cooling system, start and operate the engine with the fill cap off until the coolant level stabilizes. Add coolant as necessary to fill the system.When the engine is shipped from the factory, its cooling system is protected to -28°C (-20°F), with permanent-type antifreeze.Operate with a thermostat in the cooling system year-round. Overheating can arise without a thermostat.Fuel System

Fill the fuel tank at the end of each day of operation to drive out moist air and to prevent condensation. Do not fill the tank to the top. The fuel expands as it gets warm and may overflow.

Do not fill the fuel filters with fuel before installing them. Contaminated fuel will cause accelerated wear to the fuel system parts.

Check the fuel level with the dipstick in the filler opening. Drain the water and sediment from the fuel tank at the start of a shift or after the fuel tank has been filled and allowed to stand for 5 to 10 minutes.After changing the fuel filters, always bleed the fuel system to remove air bubbles from the system.Drain water and sediment from any fuel storage tank weekly, and before the tank is refilled. This will help prevent water or sediment from being pumped from the storage tank into the machine fuel tank.Use only fuel as recommended in the 'Fuel, Coolant and Lubricant" section of this Guide.

Have questions with 101401-2310?

Group cross 101401-2310 ZEXEL

101401-2310

INJECTION-PUMP ASSEMBLY