Information injection-pump assembly

BOSCH

9 400 613 183

9400613183

ZEXEL

101401-2302

1014012302

HINO

220204251C

220204251c

Rating:

Service parts 101401-2302 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2601A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 183

9400613183

ZEXEL

101401-2302

1014012302

HINO

220204251C

220204251c

Zexel num

Bosch num

Firm num

Name

101401-2302

9 400 613 183

220204251C HINO

INJECTION-PUMP ASSEMBLY

W04C-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

W04C-T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.17

3.23

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

A

Rack position

11

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

95.5

93.5

97.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

84

84

Boost pressure

mmHg

630

630

Injection quantity adjustment_02

Adjusting point

B

Rack position

R1-0.95

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73

67

79

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.2+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.5

7

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

900

900

900

Rack position

R1-0.95

Boost pressure

kPa

26.7

24

29.4

Boost pressure

mmHg

200

180

220

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Rack position

R1(11)

Boost pressure

kPa

70.6

63.9

77.3

Boost pressure

mmHg

530

480

580

Timer adjustment

Pump speed

r/min

1275--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1225

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

1450

Advance angle

deg.

3.25

2.95

3.55

Load

4/4

Remarks

Finish

Finish

Test data Ex:

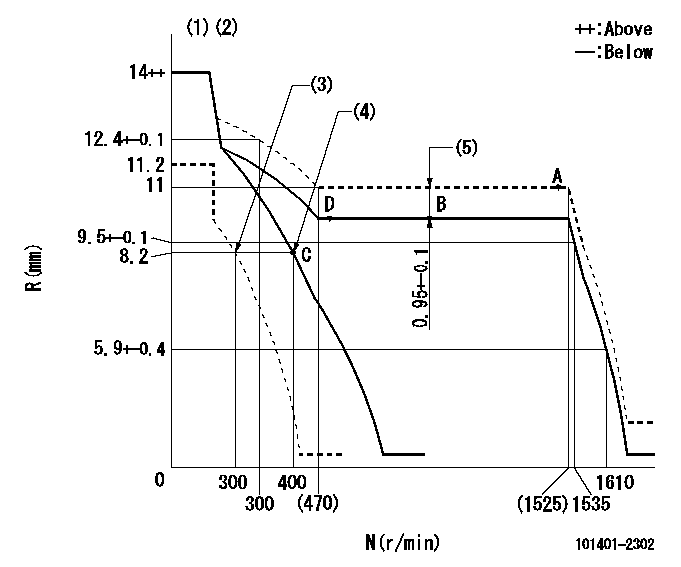

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

(4)Main spring setting

(5)Boost compensator stroke (at N = N1)

----------

K=6 N1=900r/min

----------

----------

K=6 N1=900r/min

----------

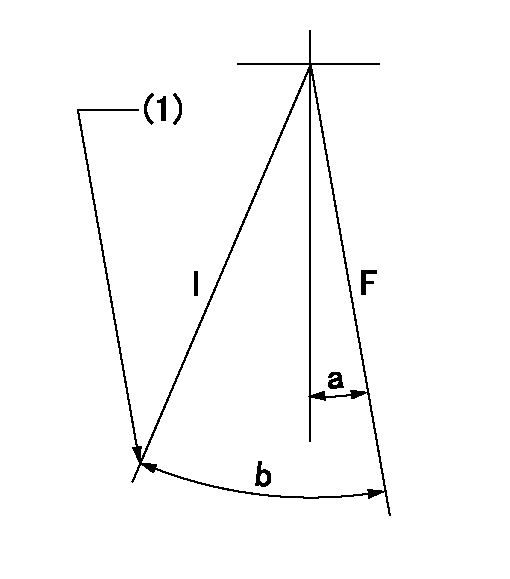

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=25deg+-5deg

----------

----------

a=9deg+-5deg b=25deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

9. If the engine oil pressure gauge does not register within 10 seconds, stop the engine by pulling up on the accelerator pedal. Have corrections made.10. Keep the engine at low idle until the systems are warm.11. Watch all gauges and indicators. They must have correct readings before moving the machine.Below 0°C (32°F)

1. Follow the steps under "Above 0°C (32°F)."

If the engine does not start after two attempts, use starting fluid. This will prevent excessive battery drain and starting motor overheating.Use starting fluid (ether) only while cranking the engine.Use sparingly, excessive ether can cause piston and ring damage.Ether is to be used for cold weather starting purposes only.

Keep batteries charged to a corrected specific gravity of 1.250 or above. Otherwise, an external electrical source may be required. 2. Use starting fluid while cranking the engine. Push the button located below the start switch, at two second intervals only. A metered amount of starting fluid (ether) is released each time the button is pushed.3. Use additional starting fluid every two seconds until the engine starts.4. Release the start switch when the engine starts. Continue to inject ether until the engine runs smoothly.For starting below - 18°C (0°F), use additional starting aids. A coolant

1. Follow the steps under "Above 0°C (32°F)."

If the engine does not start after two attempts, use starting fluid. This will prevent excessive battery drain and starting motor overheating.Use starting fluid (ether) only while cranking the engine.Use sparingly, excessive ether can cause piston and ring damage.Ether is to be used for cold weather starting purposes only.

Keep batteries charged to a corrected specific gravity of 1.250 or above. Otherwise, an external electrical source may be required. 2. Use starting fluid while cranking the engine. Push the button located below the start switch, at two second intervals only. A metered amount of starting fluid (ether) is released each time the button is pushed.3. Use additional starting fluid every two seconds until the engine starts.4. Release the start switch when the engine starts. Continue to inject ether until the engine runs smoothly.For starting below - 18°C (0°F), use additional starting aids. A coolant

Have questions with 101401-2302?

Group cross 101401-2302 ZEXEL

Hino

101401-2302

9 400 613 183

220204251C

INJECTION-PUMP ASSEMBLY

W04C-T

W04C-T