Information injection-pump assembly

BOSCH

F 019 Z10 308

f019z10308

ZEXEL

101401-2301

1014012301

HINO

220204251B

220204251b

Rating:

Service parts 101401-2301 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2601A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 308

f019z10308

ZEXEL

101401-2301

1014012301

HINO

220204251B

220204251b

Zexel num

Bosch num

Firm num

Name

F 019 Z10 308

220204251B HINO

INJECTION-PUMP ASSEMBLY

W04C-T A * K 14BC PE4A,5A, PE

W04C-T A * K 14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.17

3.23

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

A

Rack position

11

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

95.5

93.5

97.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

84

84

Boost pressure

mmHg

630

630

Injection quantity adjustment_02

Adjusting point

B

Rack position

R1-0.95

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73

67

79

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.2+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.5

7

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

900

900

900

Rack position

R1-0.95

Boost pressure

kPa

26.7

24

29.4

Boost pressure

mmHg

200

180

220

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Rack position

R1(11)

Boost pressure

kPa

70.6

63.9

77.3

Boost pressure

mmHg

530

480

580

Timer adjustment

Pump speed

r/min

1275--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1225

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

1450

Advance angle

deg.

3.25

2.95

3.55

Load

4/4

Remarks

Finish

Finish

Test data Ex:

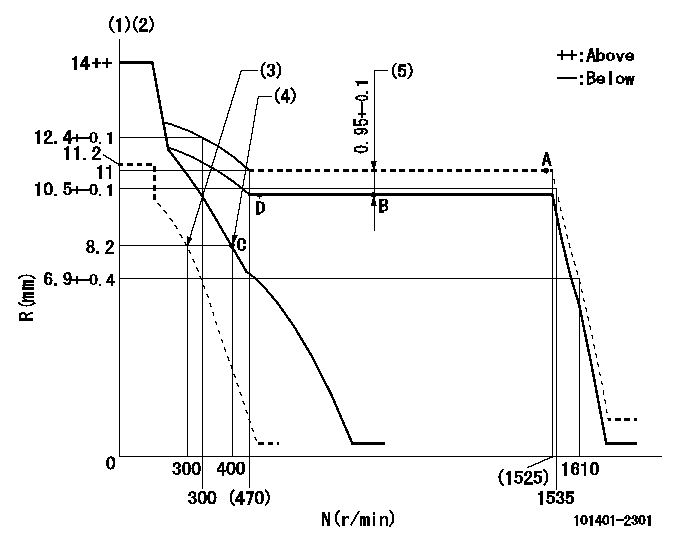

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

(4)Main spring setting

(5)Boost compensator stroke (at N = N1)

----------

K=6 N1=900r/min

----------

----------

K=6 N1=900r/min

----------

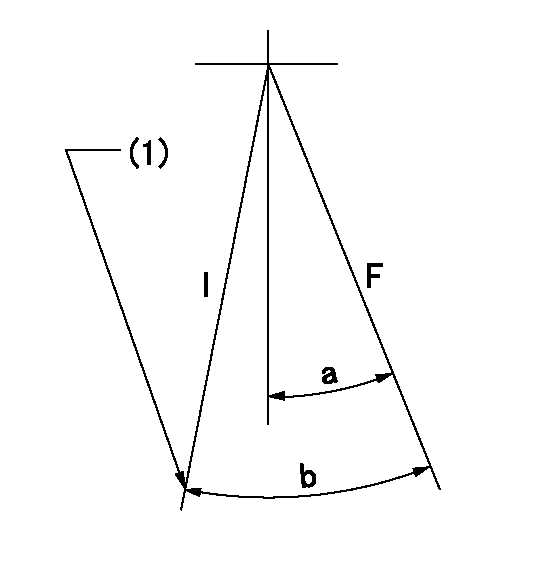

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=25deg+-5deg

----------

----------

a=9deg+-5deg b=25deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Coolant Conditioner Elements

At operating temperature, the engine coolant is hot and under pressure.Steam can cause personal injury.Check the coolant level ONLY when the engine is stopped and the radiator fill cap is cool enough to touch with your hand.Remove the fill cap slowly to relieve pressure.Cooling System Conditioner contains alkali. Avoid contact with skin and eyes to prevent personal injury.

All water is corrosive at engine operating temperature. Use Caterpillar Coolant Conditioner Elements to treat either plain water or ethylene glycol solution.Do not use Caterpillar Coolant Conditioner Elements if Dowtherm 209 Full-Fill Coolant is used. Follow the recommendations with the Dowtherm 209 Full-Fill Coolant.

Use a Caterpillar Part Number 1W5518 precharge element when the cooling system is drained and refilled. This will establish the proper initial conditioner concentration.Use a Caterpillar Part Number 9N6123 maintenance element every 250 service hours thereafter, to maintain the proper conditioner concentration.If the coolant conditioner elements have been regularly changed at 250 service hours, the change period for engine coolant can be extended to 4000 hours.Refer to the "Maintenance" (Lubrication and Maintenance) Guide for the procedures to change the antifreeze solution, or flush the cooling system.To Change Element

1. Remove the radiator cap slowly to relieve pressure in the cooling system. 2. Close the inlet valve and the outlet valve at the element base. Turn each handle clockwise to close each valve. 3. Remove the coolant conditioner element. Discard the element. 4. Clean the element mounting base. Make certain all of the old element gasket material is removed.5. Use the correct precharge or maintenance element for your cooling system. Elements are sized according to the cooling system capacity. 6. Coat the seal of the element with a thin film of clean engine oil or antifreeze. 7. Install the element. Tighten it until the seal contacts the base, then tighten it an additional 3/4 turn. 8. Open the inlet valve and the outlet valve. 9. Maintain the coolant level above the low level plate.10. Clean and install the radiator cap.11. Start the engine and check for leaks.Fuel Specifications for Direct Injection Engines

Caterpillar Diesel Engines have the ability to burn a wide variety of fuels. These fuels are divided into two general groups, preferred and permissible.Types of Fuel

The preferred fuels provide maximum engine service life and performance. They are distillate fuels. They are commonly called fuel oil, furnace oil, diesel fuel, gas oil, or kerosene.The permissible fuels are crude oils or blended fuels. Use of these fuels can result in higher maintenance costs and reduced engine service life.See Caterpillar Form Number SEHS7067, "Fuels for Caterpillar Diesel Engines," for a detailed summary of preferred and permissible fuels and their specifications.Cetane Requirement

The minimum cetane number recommended for the engine is 40.Fuel Cloud Point

Fuel waxing can plug the fuel filters in cold weather. The fuel cloud point must be below the temperature of the surrounding air to prevent filter waxing and power loss. Fuel heating attachments are available from your Caterpillar dealer to minimize fuel filter waxing.Fuel Sulfur Content

The percent of sulfur

At operating temperature, the engine coolant is hot and under pressure.Steam can cause personal injury.Check the coolant level ONLY when the engine is stopped and the radiator fill cap is cool enough to touch with your hand.Remove the fill cap slowly to relieve pressure.Cooling System Conditioner contains alkali. Avoid contact with skin and eyes to prevent personal injury.

All water is corrosive at engine operating temperature. Use Caterpillar Coolant Conditioner Elements to treat either plain water or ethylene glycol solution.Do not use Caterpillar Coolant Conditioner Elements if Dowtherm 209 Full-Fill Coolant is used. Follow the recommendations with the Dowtherm 209 Full-Fill Coolant.

Use a Caterpillar Part Number 1W5518 precharge element when the cooling system is drained and refilled. This will establish the proper initial conditioner concentration.Use a Caterpillar Part Number 9N6123 maintenance element every 250 service hours thereafter, to maintain the proper conditioner concentration.If the coolant conditioner elements have been regularly changed at 250 service hours, the change period for engine coolant can be extended to 4000 hours.Refer to the "Maintenance" (Lubrication and Maintenance) Guide for the procedures to change the antifreeze solution, or flush the cooling system.To Change Element

1. Remove the radiator cap slowly to relieve pressure in the cooling system. 2. Close the inlet valve and the outlet valve at the element base. Turn each handle clockwise to close each valve. 3. Remove the coolant conditioner element. Discard the element. 4. Clean the element mounting base. Make certain all of the old element gasket material is removed.5. Use the correct precharge or maintenance element for your cooling system. Elements are sized according to the cooling system capacity. 6. Coat the seal of the element with a thin film of clean engine oil or antifreeze. 7. Install the element. Tighten it until the seal contacts the base, then tighten it an additional 3/4 turn. 8. Open the inlet valve and the outlet valve. 9. Maintain the coolant level above the low level plate.10. Clean and install the radiator cap.11. Start the engine and check for leaks.Fuel Specifications for Direct Injection Engines

Caterpillar Diesel Engines have the ability to burn a wide variety of fuels. These fuels are divided into two general groups, preferred and permissible.Types of Fuel

The preferred fuels provide maximum engine service life and performance. They are distillate fuels. They are commonly called fuel oil, furnace oil, diesel fuel, gas oil, or kerosene.The permissible fuels are crude oils or blended fuels. Use of these fuels can result in higher maintenance costs and reduced engine service life.See Caterpillar Form Number SEHS7067, "Fuels for Caterpillar Diesel Engines," for a detailed summary of preferred and permissible fuels and their specifications.Cetane Requirement

The minimum cetane number recommended for the engine is 40.Fuel Cloud Point

Fuel waxing can plug the fuel filters in cold weather. The fuel cloud point must be below the temperature of the surrounding air to prevent filter waxing and power loss. Fuel heating attachments are available from your Caterpillar dealer to minimize fuel filter waxing.Fuel Sulfur Content

The percent of sulfur