Information injection-pump assembly

BOSCH

9 400 613 661

9400613661

ZEXEL

101401-2291

1014012291

HINO

220008080A

220008080a

Rating:

Service parts 101401-2291 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236001981A

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 661

9400613661

ZEXEL

101401-2291

1014012291

HINO

220008080A

220008080a

Zexel num

Bosch num

Firm num

Name

101401-2291

9 400 613 661

220008080A HINO

INJECTION-PUMP ASSEMBLY

W04C-TF * K

W04C-TF * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

4.3

4.27

4.33

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

83

81

85

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9+-0.5

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

83

82

84

Basic

*

Fixing the lever

*

Boost pressure

kPa

22.7

22.7

Boost pressure

mmHg

170

170

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.1

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

91

87

95

Fixing the lever

*

Boost pressure

kPa

22.7

22.7

Boost pressure

mmHg

170

170

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2-(1.2)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

37.6

33.6

41.6

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

D

Rack position

11.2

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

49.5

47.5

51.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

E

Rack position

R2(R1-0.

3)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

65.2

61.2

69.2

Fixing the lever

*

Boost pressure

kPa

22.7

22.7

Boost pressure

mmHg

170

170

Injection quantity adjustment_08

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

109

99

119

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

11.2

Boost pressure

kPa

2

0

4

Boost pressure

mmHg

15

15

30

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

R1+1.1

Boost pressure

kPa

9.3

9.3

9.3

Boost pressure

mmHg

70

70

70

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

(1000)

Advance angle

deg.

1.25

0.65

1.25

Load

4/4

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

1.25

0.65

1.25

Load

3/4

Timer adjustment_05

Pump speed

r/min

1500

Advance angle

deg.

4.5

4.2

4.8

Load

4/4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Idle increase set point (air cylinder's negative pressure supply: P1)

----------

T1=D20 BCL=(1.2)+-0.1mm P1=392+98kPa(4+1kgf/cm2)

----------

----------

T1=D20 BCL=(1.2)+-0.1mm P1=392+98kPa(4+1kgf/cm2)

----------

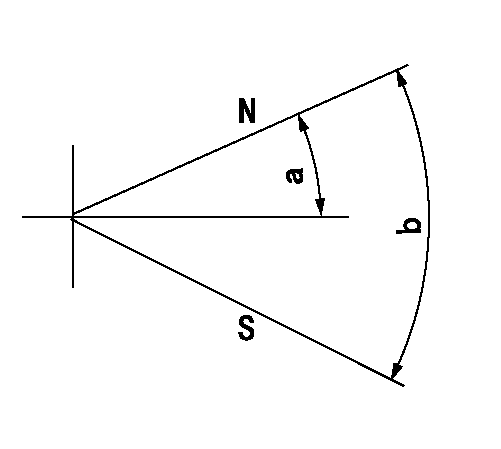

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=21.5deg+-5deg b=39deg+-3deg

----------

----------

a=21.5deg+-5deg b=39deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=13deg+-5deg b=40deg+-5deg

----------

----------

a=13deg+-5deg b=40deg+-5deg

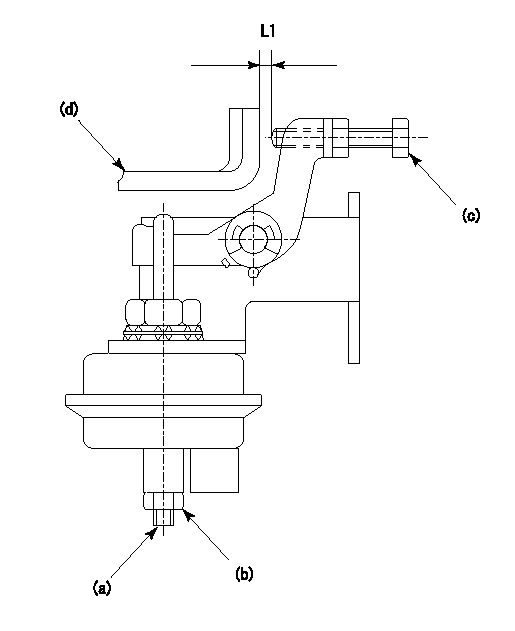

0000001501 ACTUATOR

(a) Screw

(B) Nut

(c) set bolt

(d) control lever

1. Actuator adjustment procedure

(1)Position the control lever (d) in the idling position.

(2)Set the clearance between the control lever (d) and the set bolt (c) to approx. L1.

(3)Loosen the nut (b) and fully tighten the screw (a).

(4)Set the pump speed at N1and measure the rack position when negative pressure P1 is applied to the actuator.

(5)Loosen screw (a) and fix the nut (b) when the pump speed is N2 and the rack position is R1.

(6)Confirm that control lever (d) returns to the idling position at actuator negative pressure 0.

(7)Repeat procedures (4) to (6) several times and confirm that the control lever (d) moves smoothly.

----------

L1=2mm R1=8.5~8.7mm P1=66.7kPa(500mmHg) N1=475r/min N2=475r/min

----------

----------

L1=2mm R1=8.5~8.7mm P1=66.7kPa(500mmHg) N1=475r/min N2=475r/min

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Above 16°C (60°F)

Consult the "Operation" (Operator's) Guide for before starting checks. 1. Turn on the scraper disconnect switch. 2. Move the scraper governor to just past ENGINE STOPPED detent. 3. Push in and turn the start switch to START. Release the switch when the engine starts.

After every 30 seconds of cranking, allow 2 minutes for the starting motor to cool.

4. If the engine oil pressure gauge doesn't register within 10 seconds, push the governor control to the ENGINE STOPPED position to stop the engine. Have corrections made.5. Keep the engine at low idle until the systems are warm.6. Watch all gauges and indicators for correct readings before moving the machine.16°C (60°F) to -12°C (10°F)

1. Follow the steps under "Above 16°C (60°F)."

If the engine does not start after two attempts, use starting fluid. This will prevent excessive battery drain and starting motor overheating.

2. Use starting fluid by pushing the button under the start switch, at 2 second intervals, while cranking the engine. See "Ether Aids" under "Cold Weather Starting Aids."-12°C (10°F) to -26°C (-15°F)

1. Follow the steps under "Above 16°C (60°F)."2. Coolant heaters are required.3. An external battery source may be required if the battery charge is not maintained. See "Boost Starting" under "Cold Weather Starting Aids."4. Starting fluid is required. See "Ether Aids" under "Cold Weather Starting Aids."Below -26°C (-15°F)

1. Follow the steps under "Above 16°C (60°F)."2. Coolant heaters are required.3. An external battery source may be required. See "Boost Starting" under "Cold Weather Starting Aids."4. Starting fluid is required. See "Ether Aids" under "Cold Weather Starting Aids."5. Special lubricants are required. Consult your Caterpillar dealer or refer to Caterpillar Form Number SEBU5338, "Operation, Lubrication and Maintenance Guide for Cold Weather Operation."Starting Aids

Winter Oils

The use of SAE10W viscosity oil in the compartments listed on the chart below will aid in cold weather starting.

Use SAE10W oil only in the temperature ranges indicated.

At lower than above temperatures consult your Caterpillar dealer or refer to the "Operation, Lubrication and Maintenance Guide for Cold Weather Operation," Caterpillar Form Number SEBU5338, for the correct lubricants to use.Ether Aids

Ether is a poison and is flammable.Use it only in well ventilated areas.Use it with care to avoid fires.Avoid breathing the ether vapors, or repeated contact of ether with skin.Do not use ether in environments above 90°C (200°F).

Ether is to be used for cold starting purposes only. Use ether only while cranking the engine. Use it sparingly. Excessive ether can cause piston and ring damage.

Push the button only while cranking the engine.A metered amount of starting fluid (ether) is released each time the button is pushed.After pushing the button, allow 2 seconds before pushing it again.Continue the use of starting fluid every 2 seconds after the engine starts, until it is running smoothly.Batteries

Keep batteries charged to a corrected specific gravity of 1.250 or above. Otherwise, an external electrical source may be required.Boost Starting

Do not allow cable ends to contact each other or the machine.Prevent sparks near the batteries. They could cause battery vapors (hydrogen) to explode.

When

Consult the "Operation" (Operator's) Guide for before starting checks. 1. Turn on the scraper disconnect switch. 2. Move the scraper governor to just past ENGINE STOPPED detent. 3. Push in and turn the start switch to START. Release the switch when the engine starts.

After every 30 seconds of cranking, allow 2 minutes for the starting motor to cool.

4. If the engine oil pressure gauge doesn't register within 10 seconds, push the governor control to the ENGINE STOPPED position to stop the engine. Have corrections made.5. Keep the engine at low idle until the systems are warm.6. Watch all gauges and indicators for correct readings before moving the machine.16°C (60°F) to -12°C (10°F)

1. Follow the steps under "Above 16°C (60°F)."

If the engine does not start after two attempts, use starting fluid. This will prevent excessive battery drain and starting motor overheating.

2. Use starting fluid by pushing the button under the start switch, at 2 second intervals, while cranking the engine. See "Ether Aids" under "Cold Weather Starting Aids."-12°C (10°F) to -26°C (-15°F)

1. Follow the steps under "Above 16°C (60°F)."2. Coolant heaters are required.3. An external battery source may be required if the battery charge is not maintained. See "Boost Starting" under "Cold Weather Starting Aids."4. Starting fluid is required. See "Ether Aids" under "Cold Weather Starting Aids."Below -26°C (-15°F)

1. Follow the steps under "Above 16°C (60°F)."2. Coolant heaters are required.3. An external battery source may be required. See "Boost Starting" under "Cold Weather Starting Aids."4. Starting fluid is required. See "Ether Aids" under "Cold Weather Starting Aids."5. Special lubricants are required. Consult your Caterpillar dealer or refer to Caterpillar Form Number SEBU5338, "Operation, Lubrication and Maintenance Guide for Cold Weather Operation."Starting Aids

Winter Oils

The use of SAE10W viscosity oil in the compartments listed on the chart below will aid in cold weather starting.

Use SAE10W oil only in the temperature ranges indicated.

At lower than above temperatures consult your Caterpillar dealer or refer to the "Operation, Lubrication and Maintenance Guide for Cold Weather Operation," Caterpillar Form Number SEBU5338, for the correct lubricants to use.Ether Aids

Ether is a poison and is flammable.Use it only in well ventilated areas.Use it with care to avoid fires.Avoid breathing the ether vapors, or repeated contact of ether with skin.Do not use ether in environments above 90°C (200°F).

Ether is to be used for cold starting purposes only. Use ether only while cranking the engine. Use it sparingly. Excessive ether can cause piston and ring damage.

Push the button only while cranking the engine.A metered amount of starting fluid (ether) is released each time the button is pushed.After pushing the button, allow 2 seconds before pushing it again.Continue the use of starting fluid every 2 seconds after the engine starts, until it is running smoothly.Batteries

Keep batteries charged to a corrected specific gravity of 1.250 or above. Otherwise, an external electrical source may be required.Boost Starting

Do not allow cable ends to contact each other or the machine.Prevent sparks near the batteries. They could cause battery vapors (hydrogen) to explode.

When

Have questions with 101401-2291?

Group cross 101401-2291 ZEXEL

Hino

Hino

Hino

Hino

Hino

Hino

Hino

Hino

Hino

101401-2291

9 400 613 661

220008080A

INJECTION-PUMP ASSEMBLY

W04C-TF

W04C-TF