Information injection-pump assembly

BOSCH

9 400 613 655

9400613655

ZEXEL

101401-2221

1014012221

HINO

220006460A

220006460a

Rating:

Service parts 101401-2221 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236001981A

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 655

9400613655

ZEXEL

101401-2221

1014012221

HINO

220006460A

220006460a

Zexel num

Bosch num

Firm num

Name

101401-2221

9 400 613 655

220006460A HINO

INJECTION-PUMP ASSEMBLY

W04C-TD * K

W04C-TD * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

4.4

4.37

4.43

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

98.3

96.3

100.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.2+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

21

19.5

22.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.9)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

98.3

97.3

99.3

Basic

*

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.15

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

99.7

95.7

103.7

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1-1)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

73.8

69.8

77.8

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_06

Adjusting point

D

Rack position

(R1-0.75

)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

81.9

77.9

85.9

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_07

Adjusting point

E

Rack position

-

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

55.9

51.9

59.9

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_08

Adjusting point

F

Rack position

R2-0.9

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

48

44

52

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_09

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

110

120

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

R2-0.9

Boost pressure

kPa

6.7

6.7

9.4

Boost pressure

mmHg

50

50

70

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

R2(R1-1)

Boost pressure

kPa

17.3

17.3

17.3

Boost pressure

mmHg

130

130

130

Timer adjustment

Pump speed

r/min

1350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

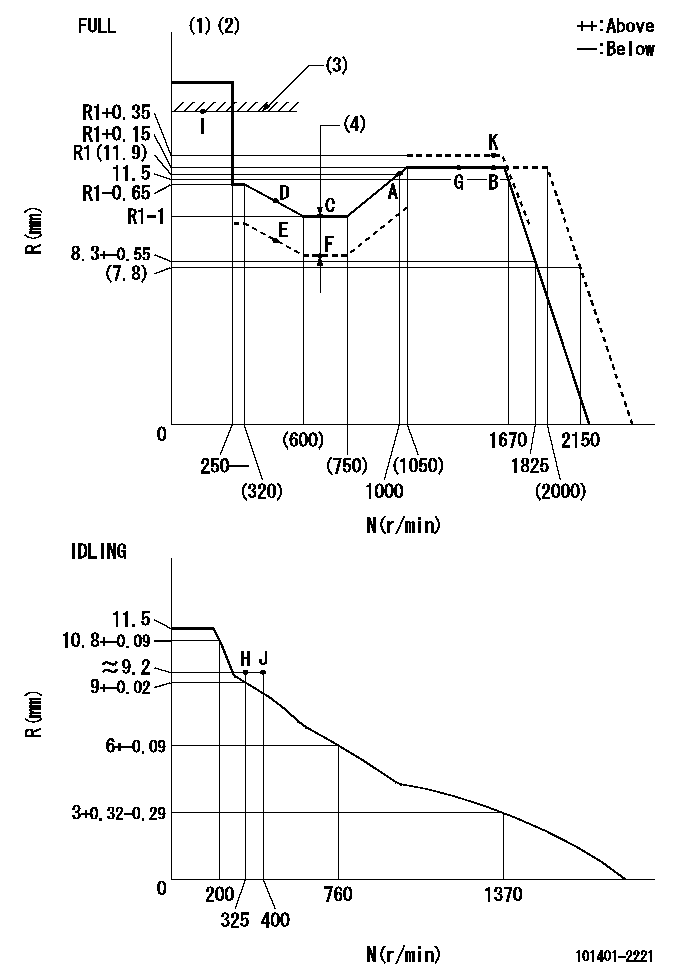

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=D36 BCL=0.9+-0.1mm

----------

----------

T1=D36 BCL=0.9+-0.1mm

----------

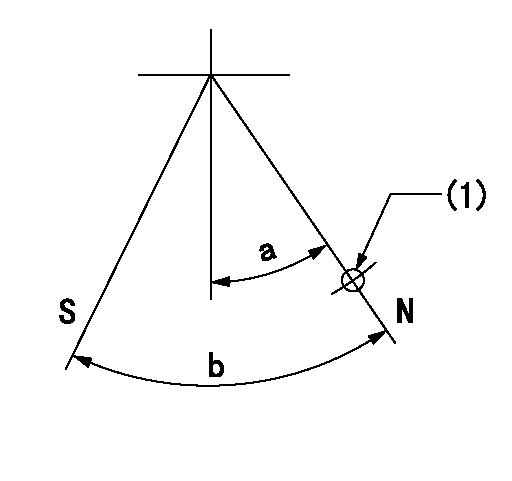

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=50mm

----------

a=34deg+-5deg b=39deg+-3deg

----------

aa=50mm

----------

a=34deg+-5deg b=39deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=35mm

----------

a=35deg+-5deg b=(40deg)+-5deg

----------

aa=35mm

----------

a=35deg+-5deg b=(40deg)+-5deg

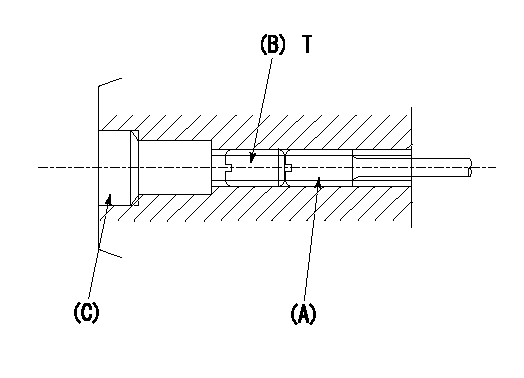

0000001501 TAMPER PROOF

1. Method for setting tamperproof proofing

(1)After governor adjustment (torque cam phase adjustment), move the load lever to increase the full rack position to Ra.

(2)At pump speed N1, push in the screw (A) until the rack position is Rb.

(3)Temporarily caulk using the tip of a screwdriver

(4)Confirm that the rack at that time is at Rc.

(5)Lock using setscrew (B). (Tightening torque = T)

(6)Next, coat (C) with adhesive and then pressfit.

(7)Then, readjust the full rack position using the load lever.

----------

N1=1600r/min Ra=(1)mm Rb=R1(11.9)+0.35mm Rc=R1(11.9)+0.35mm

----------

T=4.9~6.9N-m(0.5~0.7Kgf-m)

----------

N1=1600r/min Ra=(1)mm Rb=R1(11.9)+0.35mm Rc=R1(11.9)+0.35mm

----------

T=4.9~6.9N-m(0.5~0.7Kgf-m)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

If fuel line clamps are not installed in their exact location, vibration can cause the fuel lines to break and cause possible personal injury, or damage to the machine.

1. Disconnect front fuel injection lines (1), disconnect middle fuel injection lines (2) and rear fuel injection lines (3) from the fuel injection pump and the cylinder head assembly.2. Remove fuel injection lines (1), (2) and (3). Put caps or plugs on all fuel line connections to keep foreign material out of the fuel system.3. If a separation of the fuel lines has to be made, make sure the exact location of the clamps are marked for assembly purposes. Remove the clamps and make a separation of the fuel lines. The following steps are for the installation of the fuel injection lines.4. Remove the caps or plugs for the fuel injection line connections.5. If removed, connect the fuel lines with the clamps. Make sure the clamps are installed back in their correct location. Use Tool (A) to tighten the clamp bolts to a torque of 2.3 N m (20 lb in). For more information, see Specifications Manual SENR6470, of Testing & Adjusting Manual SENR6471.6. Install front fuel injection lines (1) on the fuel injection pump and cylinder head assembly.7 Install middle fuel injection lines (2) on the fuel injection pump and the cylinder head assembly.8. Install rear fuel injection lines (3) on the fuel injection pump and the cylinder head assembly.9. Tighten the fuel injection line nuts to a torque of 40 7 N m (30 5 lb ft).

Have questions with 101401-2221?

Group cross 101401-2221 ZEXEL

Hino

Hino

Hino

101401-2221

9 400 613 655

220006460A

INJECTION-PUMP ASSEMBLY

W04C-TD

W04C-TD