Information injection-pump assembly

ZEXEL

101401-1670

1014011670

Rating:

Cross reference number

ZEXEL

101401-1670

1014011670

Zexel num

Bosch num

Firm num

Name

101401-1670

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8820

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

65

63.4

66.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.1)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

65

64

66

Basic

*

Fixing the lever

*

Boost pressure

kPa

24

24

Boost pressure

mmHg

180

180

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.2

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

83.5

79.5

87.5

Fixing the lever

*

Boost pressure

kPa

24

24

Boost pressure

mmHg

180

180

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.4

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

48.8

44.8

52.8

Fixing the lever

*

Boost pressure

kPa

24

24

Boost pressure

mmHg

180

180

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-0.2

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

31.6

27.6

35.6

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R2-0.2

Boost pressure

kPa

5.3

4

6.6

Boost pressure

mmHg

40

30

50

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

R2(R1-0.

1)

Boost pressure

kPa

10.7

10.7

10.7

Boost pressure

mmHg

80

80

80

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

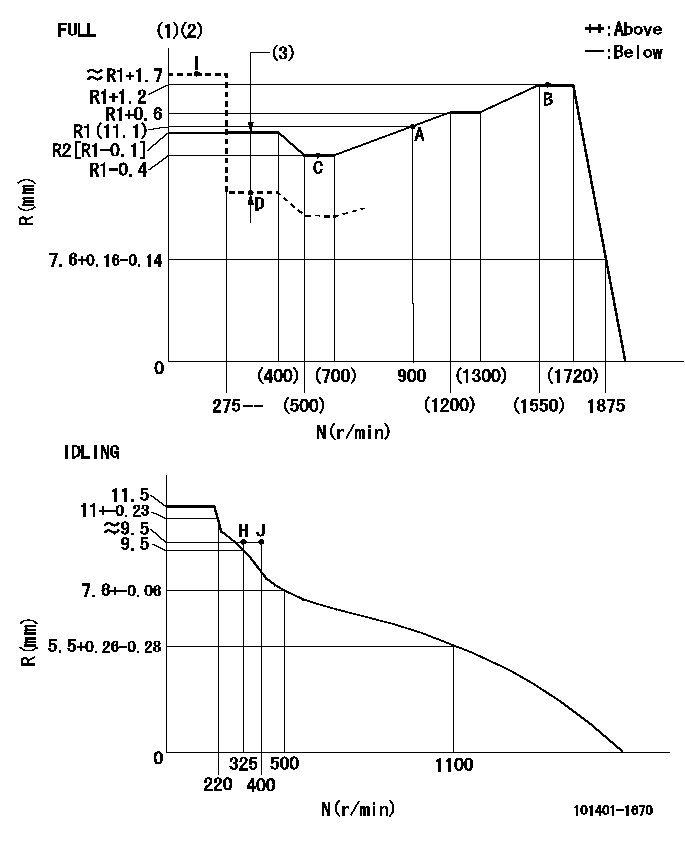

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=J10 BCL=0.2+-0.1mm

----------

----------

T1=J10 BCL=0.2+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=40mm

----------

a=26deg+-5deg b=(40deg)+-3deg

----------

aa=40mm

----------

a=26deg+-5deg b=(40deg)+-3deg

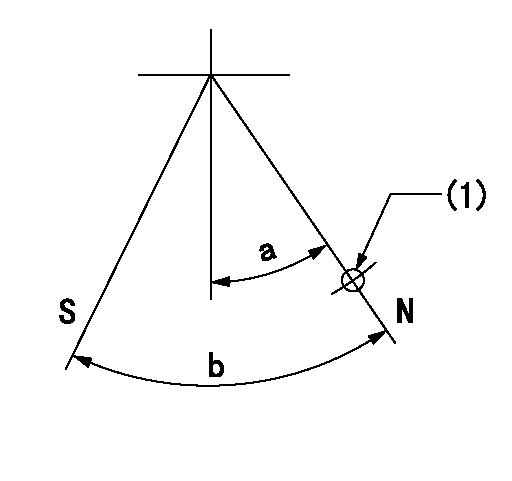

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=40mm

----------

a=33deg+-5deg b=40deg+-5deg

----------

aa=40mm

----------

a=33deg+-5deg b=40deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=1025r/min Ra=8.5+-0.1mm

----------

----------

N1=1025r/min Ra=8.5+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(130deg)

----------

aa=10deg

----------

a=(130deg)

Information:

The serial number of any injector(s) replaced in a machine covered under this service letter must be documented in the claims story. Only injectors with serial numbers between 11577640-11676551 (see action required for explanation on how to decode injector serial number) will be allowed to be claimed under this service letter.

If there has been a previous repair, part age will apply. Retain a copy of the previous repair in the dealer's records for audit purposes, and specify repair date and machine hours in the "Additional Comments" section of the warranty claim.

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 3*******

0-1000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 4.0-hour job for Group 3

The serial number of any injector(s) replaced in a machine covered under this service letter must be documented in the claims story. Only injectors with serial numbers between 11577640-11676551 (see action required for explanation on how to decode injector serial number) will be allowed to be claimed under this service letter.

If there has been a previous repair, part age will apply. Retain a copy of the previous repair in the dealer's records for audit purposes, and specify repair date and machine hours in the "Additional Comments" section of the warranty claim.

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 4*******

0-1000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 4.0-hour job for Group 4

The serial number of any injector(s) replaced in a machine covered under this service letter must be documented in the claims story. Only injectors with serial numbers between 11577640-11676551 (see action required for explanation on how to decode injector serial number) will be allowed to be claimed under this service letter.

If there has been a previous repair, part age will apply. Retain a copy of the previous repair in the dealer's records for audit purposes, and specify repair date and machine hours in the "Additional Comments" section of the warranty claim.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101401-1670?

Group cross 101401-1670 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

101401-1670

INJECTION-PUMP ASSEMBLY