Information injection-pump assembly

ZEXEL

101401-0610

1014010610

Rating:

Cross reference number

ZEXEL

101401-0610

1014010610

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.3

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

74.5

72.9

76.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.6+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.3)

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

74.5

73.5

75.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

I

Rack position

14.4+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

79

79

87

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1000+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1600

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=B19

----------

----------

T1=B19

----------

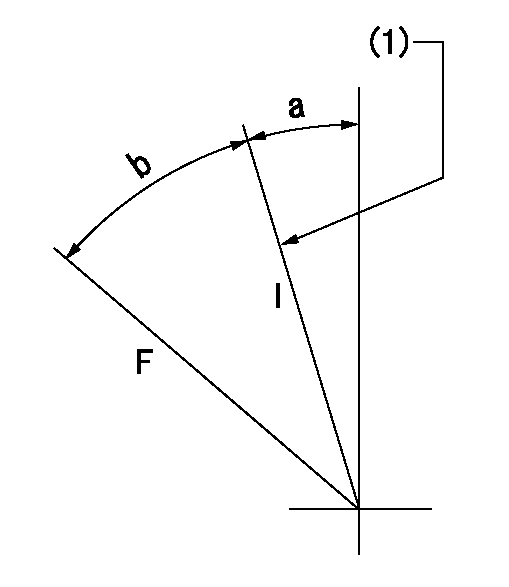

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=2.5deg+-5deg b=32deg+-3deg

----------

----------

a=2.5deg+-5deg b=32deg+-3deg

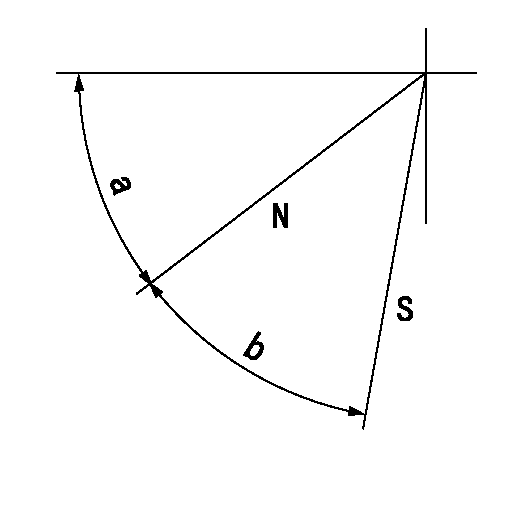

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=45deg+-5deg b=40deg+-5deg

----------

----------

a=45deg+-5deg b=40deg+-5deg

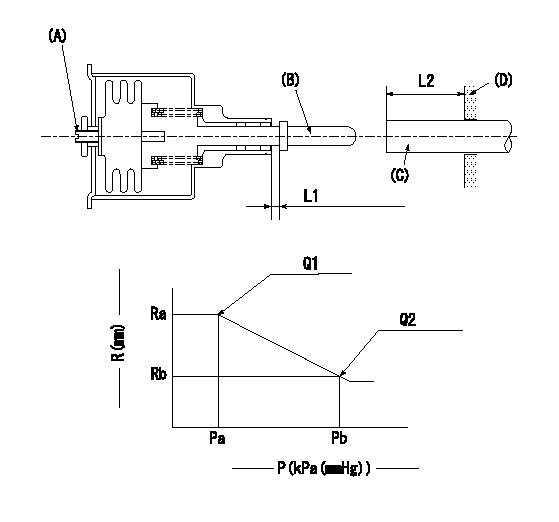

0000001501 ACS

(A) Set screw

(B) Push rod 1

(C) Push rod 2

(D) Cover

1. Aneroid compensator unit adjustment

(1)Select the push rod 2 to obtain L2.

(2)Screw in (A) to obtain L1.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Screw in the aneroid compensator to obtain the performance shown in the graph above.

(3)As there is hysterisis, measure when the absolute pressure drops.

(4)Hysterisis must not exceed rack position = h1.

----------

N1=950r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R1(12.3)mm Rb=(R1-0.3)mm Pa=89.8+-2.7kPa(674+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=74.5+-1cm3/1000st Q2=71+-1.5cm3/1000st

----------

N1=950r/min L1=(1.5)mm L2=11+-0.5mm h1=0.15mm

----------

Ra=R1(12.3)mm Rb=(R1-0.3)mm Pa=89.8+-2.7kPa(674+-20mmHg) Pb=70.1+-0.7kPa(526+-5mmHg) Q1=74.5+-1cm3/1000st Q2=71+-1.5cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(100deg)

----------

aa=14deg

----------

a=(100deg)

Information:

Fig. 37-Injection Line to Injection Pump Screw TorqueConnect injection lines to injection pump using NEW washers (Fig. 37).Injection line to injection pump screw torque ... 35 lb-ft(47 N m)

Fig. 38-Fuel Supply and Return LinesConnect fuel supply line (1, Fig. 38) and fuel return line (2).Fuel supply line connection torque (1) ... 20 lb-ft(27 N m)Fuel return line connection torque (2) ... 20 lb-ft(27 N m)Connect throttle linkage, remove timing window, and install timing hole cover.Bleed the fuel system (Group 0413).See Group 9010 for adjustments.4-239T, 4-276T, 6-359T, 6-414D or 6-414T Engine

Position number one piston at top dead center on compression stroke.

Fig. 39-19918 Timing WindowRemove timing hole cover and install 19918 Timing Window (Fig. 39) on injection pump.Check pump mounting flange packing for damage or wear. Replace if necessary.

Fig. 40-Injection Pump Timing LinesRotate pump drive shaft and align timing lines (Fig. 40) on governor weight retainer and cam ring.Position pump on engine front plate making sure Woodruff key enters drive gear.

Fig. 41-Injection Pump Drive Gear NutInstall washer and nut on oiled pump drive shaft (Fig. 41).Injection pump drive gear nut torque (oiled) ... 150 lb-ft(203 N m)

Fig. 42-Injection Pump Attaching NutsInstall pump attaching nuts (Fig. 42) finger tight.Rotate injection pump housing counterclockwise (viewed from flywheel end) as far as possible.Rotate crankshaft counterclockwise (viewed from front end) approximately 180°. Reverse rotation and reposition number one piston at top dead center on compression stroke.Rotate injection pump housing clockwise (viewed from flywheel end) until timing lines align.Tighten injection pump attaching nuts (Fig. 42).Injection pump attaching nut torque ... 20 lb-ft(27 N m)Rotate crankshaft counterclockwise (viewed from front end) approximately 180°. Reverse rotation and reposition number one piston at top dead center on compression stroke.Injection pump timing lines should be aligned. If not, retime injection pump.

Fig. 43-Fuel Supply and Return LinesConnect fuel supply line (1, Fig. 43), fuel return line (2) and fuel injection lines (3).Fuel line connection torque (1) ... 20 lb-ft(27 N m)Fuel return line ... 20 lb-ft(27 N m)Fuel injection line connector torque ... 20 lb-ft(27 N m)Connect throttle linkage, remove timing window, and install timing hole cover.Bleed the fuel system (Group 0413).See Group 9010 for adjustments.Bleeding

Fig. 44-Fuel Filter Bleed ScrewLoosen fuel filter bleed screw (Fig. 44).

Fig. 45-Fuel Transfer Pump Primer LeverPump primer lever (Fig. 45), located on fuel transfer pump, until no air flows from bleed screw.Tighten the bleed screw.All Engines Except 3-179D

Fig. 46-Fuel Supply Line ConnectionSlightly crack fuel supply line connection at injection pump (Fig. 46) and pump primer lever until no air flows from fuel supply line connection.Tighten fuel supply line connection to 20 lb-ft (27 N m).Leave primer lever positioned toward the cylinder block.Loosen each nozzle inlet connector and turn engine until fuel flows form connector.Tighten nozzle inlet connector to 35 lb-ft (47 N m).3-179D Engine

If engine will not start after bleeding fuel filter, bleed fuel injection pump as follows:

Fig. 47-Roto-Diesel Fuel Injection Pump Bleed ScrewsLoosen lower bleed screw (B, Fig. 47).Pump primer lever on fuel transfer pump until fuel