Information injection-pump assembly

ZEXEL

101401-0370

1014010370

ISUZU

8941310090

8941310090

Rating:

Cross reference number

ZEXEL

101401-0370

1014010370

ISUZU

8941310090

8941310090

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

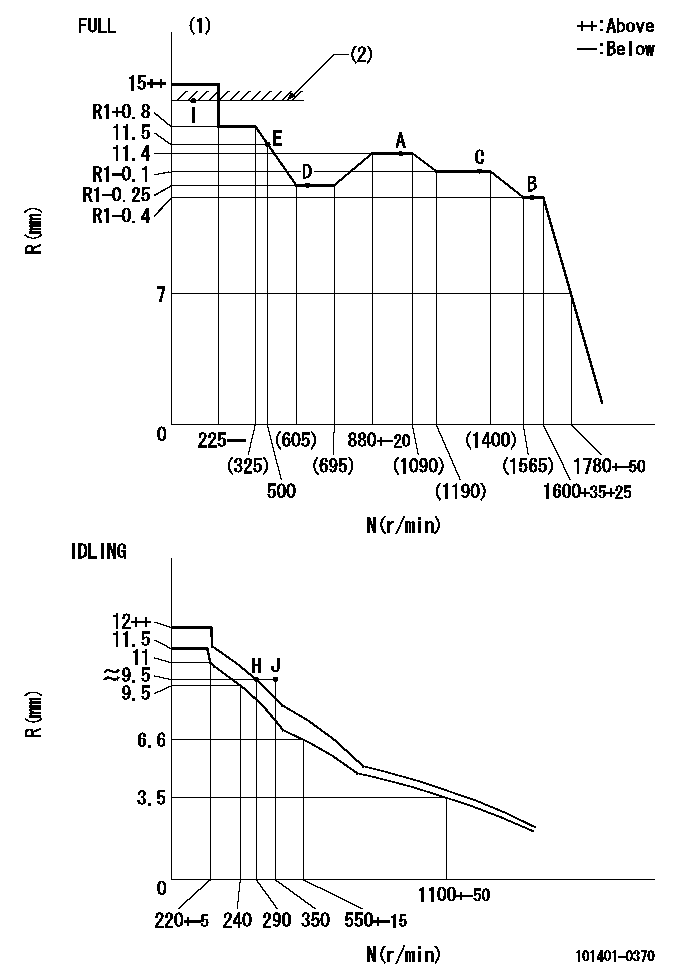

Injection quantity adjustment

Adjusting point

-

Rack position

11.4

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

70.5

69

72

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.4)

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

70.5

69.5

71.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

11+-0.5

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

70.7

67.5

73.9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

11.3+-0.

5

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

76

72.8

79.2

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

11.15+-0

.5

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

53.5

50.3

56.7

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

E

Rack position

R2(11.5)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

55

51

59

Fixing the lever

*

Injection quantity adjustment_08

Adjusting point

I

Rack position

14.5+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

95

95

103

Fixing the rack

*

Timer adjustment

Pump speed

r/min

1350+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1600

Advance angle

deg.

5

4

5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT: RAL

----------

T1=47 RAL=(14.5)mm

----------

----------

T1=47 RAL=(14.5)mm

----------

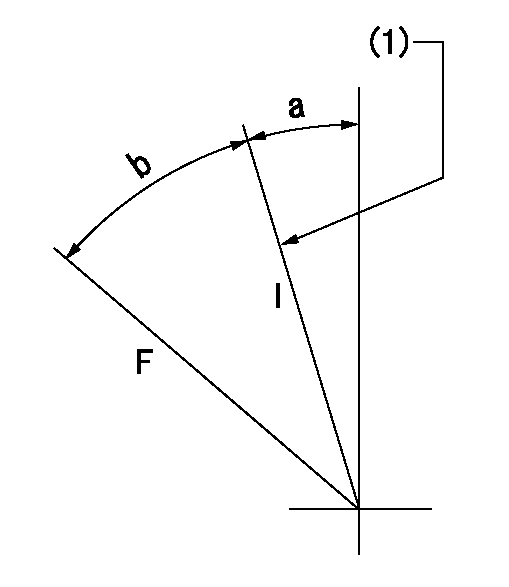

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=5.5deg+-5deg b=41deg+-3deg

----------

----------

a=5.5deg+-5deg b=41deg+-3deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(100deg)

----------

aa=13deg

----------

a=(100deg)

Information:

Image1.4.1

5. Remove two 135-8573 Bolts from the 268-0555 Hood Group, and remove the 244-8226 Support Assembly.

Image1.5.1

6. Rework the 244-8226 Support Assembly. Refer to the attached images.

Image1.6.1

7. Remove four 135-8573 Bolts from the 268-0555 Hood Group. Remove the 262-2340 Sheet Assembly.

Image1.7.1

8. Rework the 262-2340 Sheet Assembly. Refer to the attached images.

Image1.8.1

10. Attach the 324-4078 Support Assembly to the 262-2340 Sheet Assembly. Use two 135-8573 Bolts and tighten the bolts to a torque of 60+/-10 Nm.

Image1.9.1

11. To attach the 262-2340 Sheet Assembly to the 268-0555 Hood Group, use the four 135-8573 Bolts from Step-7. Tighten the bolts to a torque of 100+/-20 Nm.

12. To attach the 244-8226 Support Assembly to the 268-0555 Hood Group, use the two 135-8573 Bolts from Step-5. Tighten the bolts to a torque of 100+/-20 Nm.

13. To attach the 196-8236 Filter Assembly to the 244-8226 Support Assembly, use the two 8T-4182 Bolts and two 8T-4121 Washers. Tighten the bolts to a torque of 32+/-3 Nm.

Image1.12.1

14. Remove the present fuel hose which connected between the outlet of the fuel priming pump and the inlet of present filter assembly.

Image1.13.1

15. Install the 099-4437 Gasket to both connectors on the 305-4888 Hose. Connect the 305-4888 Hose to the inlet of the new filter assembly using the 094-9726 Bolt and two 095-2040 Washers. Tighten the bolt to a torque of 34+/-4 Nm. Connect the other end of the 305-4888 Hose to the outlet of the fuel priming pump using the bolt and the washer of the priming pump. Tighten the bolt to a torque of 34+/-4 Nm.

16. Install the 7I-7439 Guard( Length is 700mm) to the 305-4888 Hose.

17. Install the 099-4437 Gasket to both connectors on the 305-4887 Hose. Connect the 305-4887 Hose to the outlet of the new filter assembly and inlet of the present filter assembly. Use the 094-9726 Bolt and two 095-2040 Washers in order to connect the hose to the filter assemblies. Tighten the bolts to a torque of 34+/-4 Nm.

18. Install the 7I-7439 Guard (Length is 760mm) to the 305-4887 Hose.

19. Tighten the 094-9725 Plug with the 095-2040 Washer on top of filter base of current fuel filter and additional fuel filter. Tighten the plug to a torque of 8.8+/-1 Nm.

Image1.18.1

20. Use the 294-1833 Clamp, 7X-2533 Bolt, and the 9X-8256 Washer in order to clamp the fuel hose. Tighten the bolt to a torque of 10+/-1 Nm.

Image1.19.1

21. Use two 294-1831 Clamps, 7X-2535 Bolt, two 9X-8256 Washers, and the 5C-2890 Nut in order to clamp the fuel hose. Tighten the bolt to a torque of 10+/-1 Nm.

22. Re-install the two air intake hoses, using the two 8T-4985 Clamps from Step-4. Tighten the clamps to a torque of 4.5+/-0.5 Nm.

Image1.21.1

23. Re-attach the 244-8212 Cover Assembly to the 268-0555 Hood Group. Use the two 135-8573 Bolts, two 135-8575 Bolts, and two 170-3016 Spacers from Step-2. Tighten the bolts to a torque of 100+/-20 Nm.