Information injection-pump assembly

BOSCH

9 400 613 554

9400613554

ZEXEL

101401-0360

1014010360

ISUZU

5156014301

5156014301

Rating:

Service parts 101401-0360 INJECTION-PUMP ASSEMBLY:

1.

_

4.

SUPPLY PUMP

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 554

9400613554

ZEXEL

101401-0360

1014010360

ISUZU

5156014301

5156014301

Zexel num

Bosch num

Firm num

Name

101401-0360

9 400 613 554

5156014301 ISUZU

INJECTION-PUMP ASSEMBLY

4BD1 K

4BD1 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.5

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

71.4

69.8

73

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Timer adjustment

Pump speed

r/min

1250

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1350

Advance angle

deg.

1.1

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

1.6

Timer adjustment_04

Pump speed

r/min

1600

Advance angle

deg.

5

4

5

Remarks

Finish

Finish

Test data Ex:

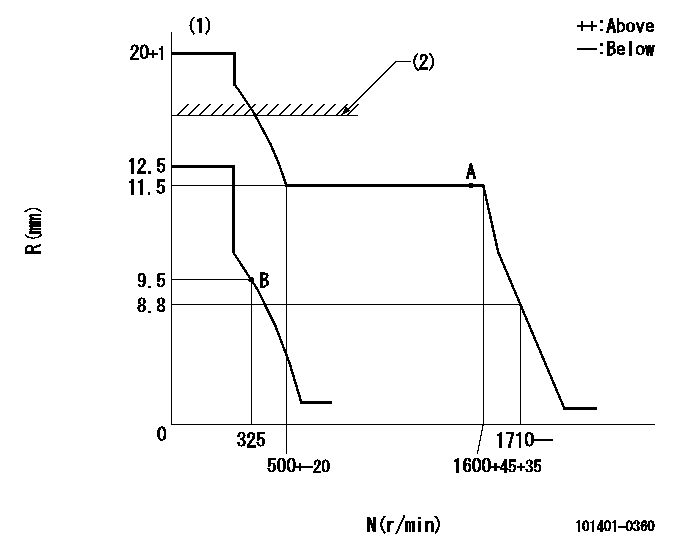

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

----------

K=10 RAL=15+-0.1mm

----------

----------

K=10 RAL=15+-0.1mm

----------

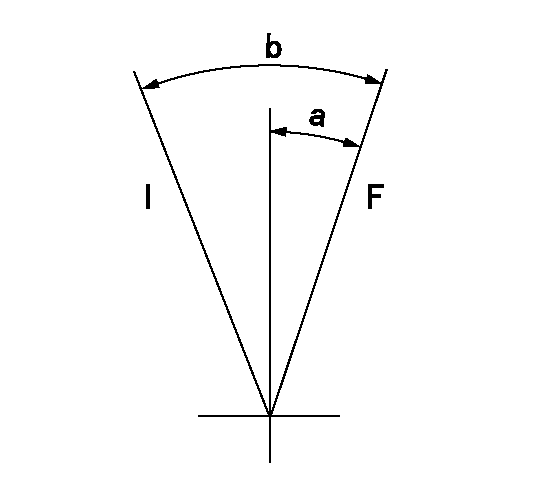

Speed control lever angle

F:Full speed

I:Idle

----------

----------

a=11deg+-5deg b=35deg+-5deg

----------

----------

a=11deg+-5deg b=35deg+-5deg

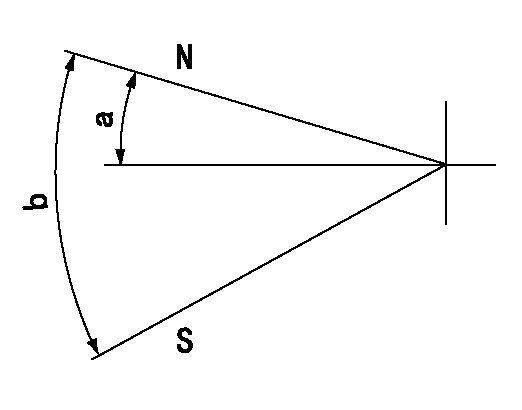

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(100deg)

----------

aa=13deg

----------

a=(100deg)

Information:

face="Courier New" size=-1>0.0% 0.0% 0.0%

This is a 5.0-hour job for Group 2

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 3*******

0-3000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 5.0-hour job for Group 3

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 4*******

0-3000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 5.0-hour job for Group 4

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 5*******

0-3000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 5.0-hour job for Group 5

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Engine Injector Change:

First identify which level of injector you currently have in your engine and establish which is the latest injector to replace it.

To remove and replace the injectors use the following Disassembly and Assembly Instructions.

C6.6 Caterpillar Industrial Engines: Install and Remove procedure RENR9722

C6.6 Caterpillar Built Machine: Install and Remove procedure KENR6081

Engine Reflash:

To update the flash file follow the procedure below. Refer to TMI or SISWeb for the latest flash file.

Tools Required:

PC or laptop with CAT ET installed and licensed (Version 2007A minimum) Communication Adaptor with diagnostic connector.

Flash File procedure:

Process:

1. Download the correct flash file from TMI or SISWeb.

2. Save the correct flash file to your local hard drive.

3. Connect to the ECM using Service Tool (CAT ET).

4. Make sure the ECM is powered up (Check that Red light on Comm. Adaptor is illuminated).

5. Go to "Winflash" or "Flash Memory".

6. CAT ET re-connect to the ECM.

7. Using the browse function in the top right hand corner, select the new flash file previously saved to hard drive.

8. Select "Begin Flash" (bottom right hand corner).

9. Once Flashing is complete select "CAT ET".

10. The Personality Module Mismatch should appear, select the ok button.

11. The factory password screen should now appear.

12. Use https://fps.cat.com to obtain factory passwords.

13. Enter Factory Passwords.

14. CAT ET High Level Configuration screen should be displayed.

15. Re-flash complete.

This is a 5.0-hour job for Group 2

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 3*******

0-3000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 5.0-hour job for Group 3

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 4*******

0-3000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 5.0-hour job for Group 4

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 5*******

0-3000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 5.0-hour job for Group 5

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Engine Injector Change:

First identify which level of injector you currently have in your engine and establish which is the latest injector to replace it.

To remove and replace the injectors use the following Disassembly and Assembly Instructions.

C6.6 Caterpillar Industrial Engines: Install and Remove procedure RENR9722

C6.6 Caterpillar Built Machine: Install and Remove procedure KENR6081

Engine Reflash:

To update the flash file follow the procedure below. Refer to TMI or SISWeb for the latest flash file.

Tools Required:

PC or laptop with CAT ET installed and licensed (Version 2007A minimum) Communication Adaptor with diagnostic connector.

Flash File procedure:

Process:

1. Download the correct flash file from TMI or SISWeb.

2. Save the correct flash file to your local hard drive.

3. Connect to the ECM using Service Tool (CAT ET).

4. Make sure the ECM is powered up (Check that Red light on Comm. Adaptor is illuminated).

5. Go to "Winflash" or "Flash Memory".

6. CAT ET re-connect to the ECM.

7. Using the browse function in the top right hand corner, select the new flash file previously saved to hard drive.

8. Select "Begin Flash" (bottom right hand corner).

9. Once Flashing is complete select "CAT ET".

10. The Personality Module Mismatch should appear, select the ok button.

11. The factory password screen should now appear.

12. Use https://fps.cat.com to obtain factory passwords.

13. Enter Factory Passwords.

14. CAT ET High Level Configuration screen should be displayed.

15. Re-flash complete.

Have questions with 101401-0360?

Group cross 101401-0360 ZEXEL

Isuzu

101401-0360

9 400 613 554

5156014301

INJECTION-PUMP ASSEMBLY

4BD1

4BD1