Information injection-pump assembly

BOSCH

9 400 612 485

9400612485

ZEXEL

101400-9060

1014009060

YANMAR

12995651020

12995651020

Rating:

Service parts 101400-9060 INJECTION-PUMP ASSEMBLY:

1.

_

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 485

9400612485

ZEXEL

101400-9060

1014009060

YANMAR

12995651020

12995651020

Zexel num

Bosch num

Firm num

Name

9 400 612 485

12995651020 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE98 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4TNE98 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.3

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

42.6

41.6

43.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.5+-0.5

Pump speed

r/min

460

460

460

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

10.1++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

80

90

Fixing the lever

*

Rack limit

*

Test data Ex:

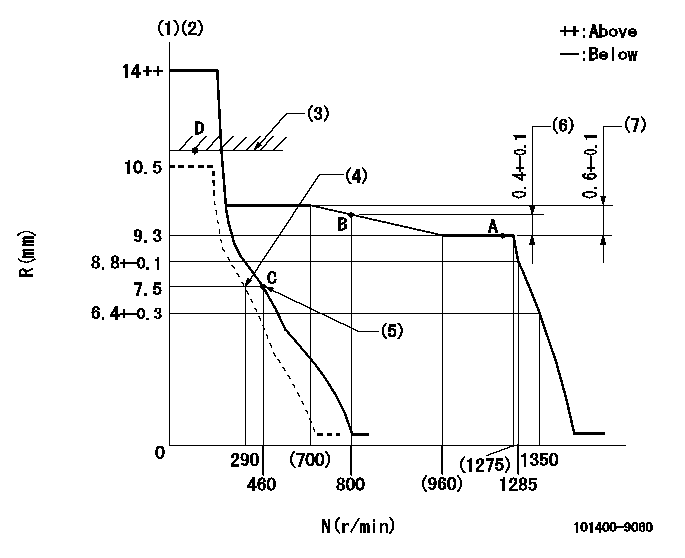

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference from N = N1

(7)Rack difference between N = N2 and N = N3

----------

K=17 N1=1250r/min N2=1250r/min N3=450r/min

----------

----------

K=17 N1=1250r/min N2=1250r/min N3=450r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=18deg+-5deg b=28deg+-5deg

----------

----------

a=18deg+-5deg b=28deg+-5deg

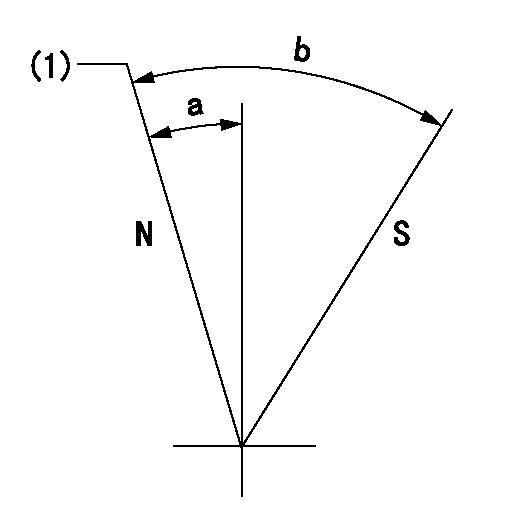

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=7deg+-5deg b=53deg+-5deg

----------

----------

a=7deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Fault Finding Chart

Key to Fault Finding Chart

1. Battery capacity low.2. Bad electrical connections.3. Faulty starter motor.4. Incorrect grade of lubricating oil.5. Low cranking speed.6. Fuel tank empty.7. Faulty stop control operation.8. Blocked fuel feed pipe.9. Faulty fuel lift pump.10. Choked fuel filter.11. Restriction in air cleaner or induction system.12. Air in fuel system.13. Faulty fuel injection pump.14. Faulty atomisers or incorrect type.15. Incorrect use of cold start equipment.16. Faulty cold starting equipment.17. Broken fuel injection pump drive.18. Incorrect fuel pump timing.19. Incorrect valve timing.20. Poor compression.21. Blocked fuel tank vent.22. Incorrect type or grade of fuel.23. Sticking throttle or restricted movement.24. Exhaust pipe restriction.25. Cylinder head gasket leaking.26. Overheating.27. Cold running.28. Incorrect tappet adjustment.29. Sticking valves.30. Incorrect high pressure pipes.31. Worn cylinder bores.32. Pitted valves and seats.33. Broken, worn or sticking piston ring/s.34. Worn valve stems and guides.35. Overfull air cleaner or use of incorrect grade of oil.36. Worn or damaged bearings.37. Insufficient oil in sump.38. Inaccurate gauge.39. Oil pump worn.40. Pressure relief valve sticking open.41. Pressure relief valve sticking closed.42. Broken relief valve spring.43. Faulty suction pipe.44. Choked oil filter.45. Piston seizure/pick up.46. Incorrect piston height.47. Damaged fan.48. Faulty engine mounting (Housing).49. Incorrect aligned flywheel housing, or flywheel.50. Faulty thermostat.51. Restriction in water jacket.52. Loose fan belt.53. Choked radiator.54. Faulty water pump.55. Choked breather pipe.56. Damaged valve stem oil deflectors (if fitted).57. Coolant level too low.58. Blocked sump strainer.59. Broken valve spring.60. Fault in exhauster or vacuum pipe leaks.61. Turbocharger impeller damaged or dirty.62. Turbocharger lubricating oil seal leaks.63. Induction system leaks (turbocharged engines).

Key to Fault Finding Chart

1. Battery capacity low.2. Bad electrical connections.3. Faulty starter motor.4. Incorrect grade of lubricating oil.5. Low cranking speed.6. Fuel tank empty.7. Faulty stop control operation.8. Blocked fuel feed pipe.9. Faulty fuel lift pump.10. Choked fuel filter.11. Restriction in air cleaner or induction system.12. Air in fuel system.13. Faulty fuel injection pump.14. Faulty atomisers or incorrect type.15. Incorrect use of cold start equipment.16. Faulty cold starting equipment.17. Broken fuel injection pump drive.18. Incorrect fuel pump timing.19. Incorrect valve timing.20. Poor compression.21. Blocked fuel tank vent.22. Incorrect type or grade of fuel.23. Sticking throttle or restricted movement.24. Exhaust pipe restriction.25. Cylinder head gasket leaking.26. Overheating.27. Cold running.28. Incorrect tappet adjustment.29. Sticking valves.30. Incorrect high pressure pipes.31. Worn cylinder bores.32. Pitted valves and seats.33. Broken, worn or sticking piston ring/s.34. Worn valve stems and guides.35. Overfull air cleaner or use of incorrect grade of oil.36. Worn or damaged bearings.37. Insufficient oil in sump.38. Inaccurate gauge.39. Oil pump worn.40. Pressure relief valve sticking open.41. Pressure relief valve sticking closed.42. Broken relief valve spring.43. Faulty suction pipe.44. Choked oil filter.45. Piston seizure/pick up.46. Incorrect piston height.47. Damaged fan.48. Faulty engine mounting (Housing).49. Incorrect aligned flywheel housing, or flywheel.50. Faulty thermostat.51. Restriction in water jacket.52. Loose fan belt.53. Choked radiator.54. Faulty water pump.55. Choked breather pipe.56. Damaged valve stem oil deflectors (if fitted).57. Coolant level too low.58. Blocked sump strainer.59. Broken valve spring.60. Fault in exhauster or vacuum pipe leaks.61. Turbocharger impeller damaged or dirty.62. Turbocharger lubricating oil seal leaks.63. Induction system leaks (turbocharged engines).