Information injection-pump assembly

ZEXEL

101400-9030

1014009030

YANMAR

12995351010

12995351010

Rating:

Cross reference number

ZEXEL

101400-9030

1014009030

YANMAR

12995351010

12995351010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.4

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

59

58

60

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.3+-0.5

Pump speed

r/min

525

525

525

Average injection quantity

mm3/st.

9

8

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

10.3++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

70

80

Fixing the lever

*

Rack limit

*

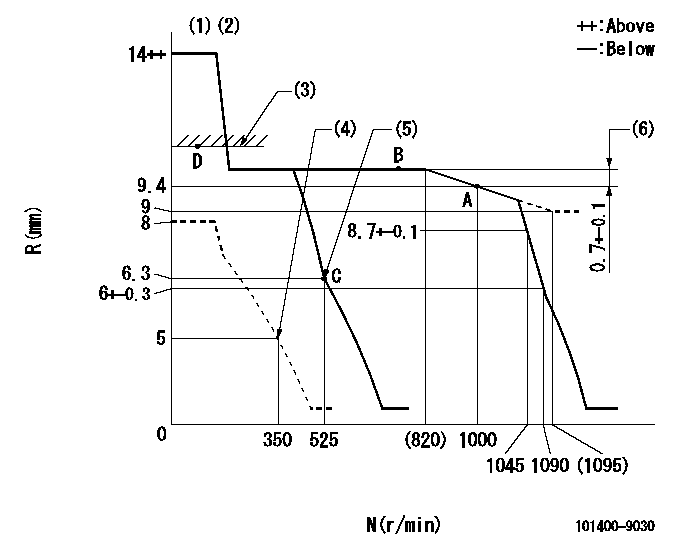

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=12 N1=1000r/min N2=700r/min

----------

----------

K=12 N1=1000r/min N2=700r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=7deg+-5deg b=18deg+-5deg

----------

----------

a=7deg+-5deg b=18deg+-5deg

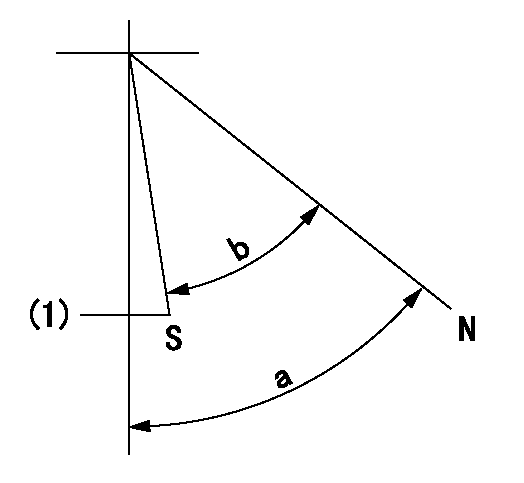

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Removing And Fitting A Starter Gear Ring

It is assumed that the flywheel is dismantled.Removing:

6-1Cut through the starter gear ring with a hard chisel and remove.Fig. 6-1Refitting:

1. Heat the starter gear ring to a temperature of 120 deg. C. Place the starter gear ring with the bevelled side of the teeth facing away from flywheel.

6-22. Locate the starter gear ring on the flywheel and tap it into position so that it seats against the shoulder.Fig. 6-2Removing And Fitting A Radial Sealing Ring On The Flywheel Side

It is assumed that the flywheel has been dismantled. Removing:

6-3Apply puller No. 142700 and draw off radial sealing ring.Fig. 6-3Refitting:

6-41. Mount guide-piece of device onto crankshaft.Fig. 6-4

6-52. Lightly grease the sealing lip of the new radial seal. Place seal on guide-piece with lip facing towards crankcase and press in with device No. 142530.Fig. 6-5 Inspect crankshaft in the zone of radial seal contact. If a friction groove has been formed by the radial seal, displace the complete cover by adding gaskets accordingly.Dismantling, Installing And Sealing The Cover On The Flywheel Side (As from 3-cylinder engine)

The flywheel has already been removed.Dismantling:

1. Remove the bolts in the oil sump securing the cover on the flywheel side and the bolts securing the cover to the crankcase. Remove cover and gasket. Renew radial sealing ring. Inspect crankshaft in the zone of radial seal contact. If a friction groove has been formed by the radial seal, displace the latter in the cover.Installing:

6-112. Adhere new gasket to crankcase. Trim off the portion of gasket projecting beyond the joint surface of the sump. Fig. 6-113. Apply coat of Deutz DW 48 jointing compound to the oil sump gasket in the region of the cover.

6-124. Press new radial seal into the rear cover so that the outside surface is flush (arrow).Fig. 6-12 Prior to fitting, heat cover "hand-warm" and coat radial seal with jointing compound.

6-135. Place cover in position. Lightly pretighten cover bolts in crankcase. Fully tighten sump bolts in cover, then fully tighten bolts in crankcase.Fig. 6-13Exploded Views

It is assumed that the flywheel is dismantled.Removing:

6-1Cut through the starter gear ring with a hard chisel and remove.Fig. 6-1Refitting:

1. Heat the starter gear ring to a temperature of 120 deg. C. Place the starter gear ring with the bevelled side of the teeth facing away from flywheel.

6-22. Locate the starter gear ring on the flywheel and tap it into position so that it seats against the shoulder.Fig. 6-2Removing And Fitting A Radial Sealing Ring On The Flywheel Side

It is assumed that the flywheel has been dismantled. Removing:

6-3Apply puller No. 142700 and draw off radial sealing ring.Fig. 6-3Refitting:

6-41. Mount guide-piece of device onto crankshaft.Fig. 6-4

6-52. Lightly grease the sealing lip of the new radial seal. Place seal on guide-piece with lip facing towards crankcase and press in with device No. 142530.Fig. 6-5 Inspect crankshaft in the zone of radial seal contact. If a friction groove has been formed by the radial seal, displace the complete cover by adding gaskets accordingly.Dismantling, Installing And Sealing The Cover On The Flywheel Side (As from 3-cylinder engine)

The flywheel has already been removed.Dismantling:

1. Remove the bolts in the oil sump securing the cover on the flywheel side and the bolts securing the cover to the crankcase. Remove cover and gasket. Renew radial sealing ring. Inspect crankshaft in the zone of radial seal contact. If a friction groove has been formed by the radial seal, displace the latter in the cover.Installing:

6-112. Adhere new gasket to crankcase. Trim off the portion of gasket projecting beyond the joint surface of the sump. Fig. 6-113. Apply coat of Deutz DW 48 jointing compound to the oil sump gasket in the region of the cover.

6-124. Press new radial seal into the rear cover so that the outside surface is flush (arrow).Fig. 6-12 Prior to fitting, heat cover "hand-warm" and coat radial seal with jointing compound.

6-135. Place cover in position. Lightly pretighten cover bolts in crankcase. Fully tighten sump bolts in cover, then fully tighten bolts in crankcase.Fig. 6-13Exploded Views