Information injection-pump assembly

BOSCH

9 400 612 483

9400612483

ZEXEL

101400-9022

1014009022

YANMAR

12995551020

12995551020

Rating:

Service parts 101400-9022 INJECTION-PUMP ASSEMBLY:

1.

_

4.

SUPPLY PUMP

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 483

9400612483

ZEXEL

101400-9022

1014009022

YANMAR

12995551020

12995551020

Zexel num

Bosch num

Firm num

Name

9 400 612 483

12995551020 YANMAR

INJECTION-PUMP ASSEMBLY

4TNE98 * K 14BC PE4A,5A, PE

4TNE98 * K 14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

72

71

73

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

11.5

10.5

12.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

11.8++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

70

80

Fixing the lever

*

Rack limit

*

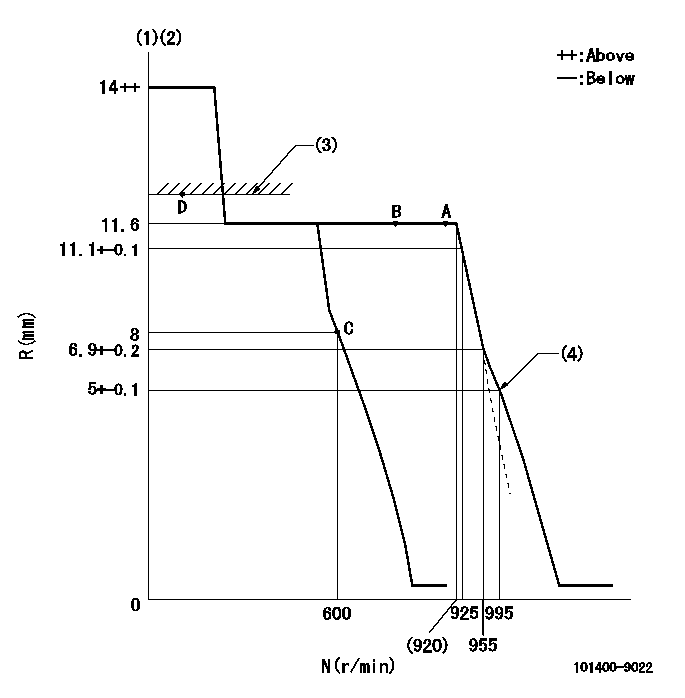

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

----------

K=11

----------

----------

K=11

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=4deg+-5deg b=13deg+-5deg

----------

----------

a=4deg+-5deg b=13deg+-5deg

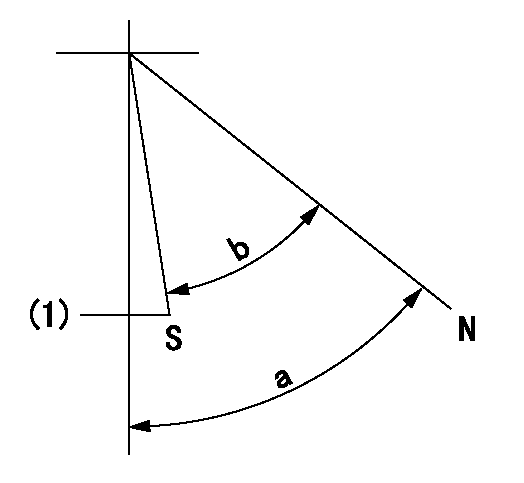

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Dismantling And Installing The Camshaft (as from 3 cylinder engine)

Fasten engine in rotatable engine stand.Dismantling

4-561. Remove the rocker chamber covers and the rocker brackets. Take out the push-rods. Remove cooling blower, crankcase breather tube, oil pan and oil suction pipe with strainer.Fig. 4-56

4-572. Remove V-belt pulley and front cover. (Retainer for V-belt pulley No. 143400)Fig. 4-57 The V-belt pulley bolt has left-hand thread.

4-583. Remove oil pipe with oil pump. Take off idler gear with hub.Fig. 4-58

4-594. Pull out camshaft.Fig. 4-59Installing

1. Position the gearwheels with the marks lines up and carefully insert the camshaft with gear. Note that the marking on the injection pump gear differs, depending on the number of engine cylinder (3 cylinders, or 4, 5, 6 cylinders.)

4-60a) F3L: The reference mark on the injection pump gearwheel of this model is a figure 3 with a dot above it. Fig. 4-60

4-61b) F4/5/6L: Engines of these types have a dot to mark the mating point of the injection pump gearwheel.Fig. 4-61 Pay attention to modified marks on camshaft and injection pump gears.2. Fit a new rubber O-seal on the discharge pipe of the oil pump.3. Position the oil pump and pipe on the crankcase and tighten the oil pump screws. Adjust the gear flank clearance to the value stated in the specifications. The manufacturing material and tightening torque for the bolts fastening the lube oil pump have been changed.

4-624. Tighten and lock down the stud securing the idler gear mounting (on the oil delivery pipe clip), in accordance with the instructions for tightening bolts and studs.Fig. 4-62

4-635. Fit oil suction pipe with strainer.Fig. 4-63

4-646. Place compression spring and cap on camshaft spigot.Fig. 4-64

4-657. Fit a new gasket to the front cover, strick it in position with grease and mount the cover.Fig. 4-65

4-668. Grease the lip of the radial packing ring in the front cover and the contact surface of the vee-belt pulley. Install the vee-belt pulley, having brought the locating pin in the crankshaft gearwheel.Fig. 4-66

4-679. Screw in bolt (left-hand thread), preload and tighten as per instructions. (Retainer for V-belt pulley No. 143400, gauge No. 101910).Fig. 4-6710. Apply grease to a new gasket and stick it in position on the sump. Assemble the sump. Tightening torque for the oil drain plugs illustrated is: 150 Nm

4-6811. Fasten retainer for crankcase breather pipe at oil pan.Fig. 4-6812. Assemble the push-rods.

4-6913. Mount the rocker brackets. Tighten nuts as quoted in Specification Data.Fig. 4-69

4-7014. Adjust the valve clearance.Fig. 4-7015. Stick new gasket with sealing compound to rocker chamber cover. Position cover, align and fit bolt with new washer. Tightening see Specification Data.

4-7116. Align blower to holes and attach to front-end cover.Fig. 4-7117. Push idler pulley upward and install belt.18. Hook in the air cowling at the top and close at the bottom.Checking And Gauging The Crankshaft

1. Inspect crankshaft for cracks (by magnaflux method).2. Remove the gearwheel from the crankshaft.3. Support crankshaft at outer main journals on prism-shaped blocks.

4-724. Determine the hardness of the journal surfaces with a scleroscope. Conversions of the redlings

Fasten engine in rotatable engine stand.Dismantling

4-561. Remove the rocker chamber covers and the rocker brackets. Take out the push-rods. Remove cooling blower, crankcase breather tube, oil pan and oil suction pipe with strainer.Fig. 4-56

4-572. Remove V-belt pulley and front cover. (Retainer for V-belt pulley No. 143400)Fig. 4-57 The V-belt pulley bolt has left-hand thread.

4-583. Remove oil pipe with oil pump. Take off idler gear with hub.Fig. 4-58

4-594. Pull out camshaft.Fig. 4-59Installing

1. Position the gearwheels with the marks lines up and carefully insert the camshaft with gear. Note that the marking on the injection pump gear differs, depending on the number of engine cylinder (3 cylinders, or 4, 5, 6 cylinders.)

4-60a) F3L: The reference mark on the injection pump gearwheel of this model is a figure 3 with a dot above it. Fig. 4-60

4-61b) F4/5/6L: Engines of these types have a dot to mark the mating point of the injection pump gearwheel.Fig. 4-61 Pay attention to modified marks on camshaft and injection pump gears.2. Fit a new rubber O-seal on the discharge pipe of the oil pump.3. Position the oil pump and pipe on the crankcase and tighten the oil pump screws. Adjust the gear flank clearance to the value stated in the specifications. The manufacturing material and tightening torque for the bolts fastening the lube oil pump have been changed.

4-624. Tighten and lock down the stud securing the idler gear mounting (on the oil delivery pipe clip), in accordance with the instructions for tightening bolts and studs.Fig. 4-62

4-635. Fit oil suction pipe with strainer.Fig. 4-63

4-646. Place compression spring and cap on camshaft spigot.Fig. 4-64

4-657. Fit a new gasket to the front cover, strick it in position with grease and mount the cover.Fig. 4-65

4-668. Grease the lip of the radial packing ring in the front cover and the contact surface of the vee-belt pulley. Install the vee-belt pulley, having brought the locating pin in the crankshaft gearwheel.Fig. 4-66

4-679. Screw in bolt (left-hand thread), preload and tighten as per instructions. (Retainer for V-belt pulley No. 143400, gauge No. 101910).Fig. 4-6710. Apply grease to a new gasket and stick it in position on the sump. Assemble the sump. Tightening torque for the oil drain plugs illustrated is: 150 Nm

4-6811. Fasten retainer for crankcase breather pipe at oil pan.Fig. 4-6812. Assemble the push-rods.

4-6913. Mount the rocker brackets. Tighten nuts as quoted in Specification Data.Fig. 4-69

4-7014. Adjust the valve clearance.Fig. 4-7015. Stick new gasket with sealing compound to rocker chamber cover. Position cover, align and fit bolt with new washer. Tightening see Specification Data.

4-7116. Align blower to holes and attach to front-end cover.Fig. 4-7117. Push idler pulley upward and install belt.18. Hook in the air cowling at the top and close at the bottom.Checking And Gauging The Crankshaft

1. Inspect crankshaft for cracks (by magnaflux method).2. Remove the gearwheel from the crankshaft.3. Support crankshaft at outer main journals on prism-shaped blocks.

4-724. Determine the hardness of the journal surfaces with a scleroscope. Conversions of the redlings