Information injection-pump assembly

BOSCH

9 400 611 780

9400611780

ZEXEL

101342-9070

1013429070

Rating:

Service parts 101342-9070 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 780

9400611780

ZEXEL

101342-9070

1013429070

Zexel num

Bosch num

Firm num

Name

101342-9070

9 400 611 780

DAEWOO

INJECTION-PUMP ASSEMBLY

3AB1 * K

3AB1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

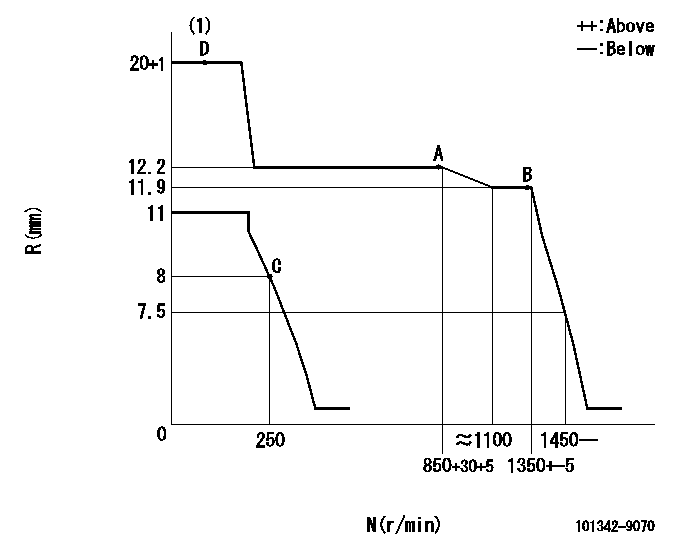

Injection quantity adjustment

Adjusting point

A

Rack position

12.2

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

39

37.9

40.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.9

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

42.3

40.8

43.8

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

8.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

9

7.7

10.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

66.3

66.3

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=15

----------

----------

K=15

----------

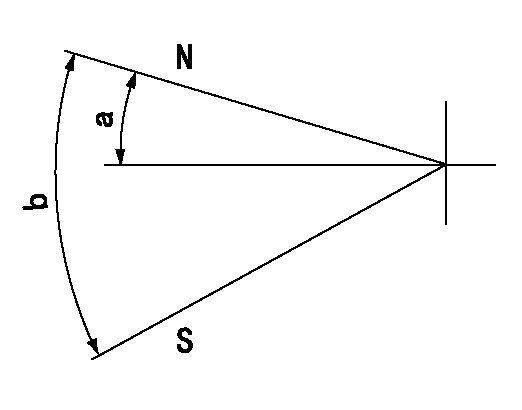

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=18.5deg+-5deg b=33deg+-5deg

----------

----------

a=18.5deg+-5deg b=33deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Z' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(120deg)

----------

aa=18deg

----------

a=(120deg)

Information:

Climbing equipment may be required to access this service point. Refer to the Operation and Maintenance Manual, "Mounting and Dismounting" topic for safety information.

Before servicing/performing maintenance on the machine, electrical power must be physically disconnected; battery plugs must be disconnected from the batteries, or the trailing cable must be unplugged, and warning tags and padlocks shall be applied by a certified electrician. Certified electricians shall perform or direct any electrical work, including any energized testing, repair work in controllers, motors, or other approved compartments, and shall insure that all compartments are properly closed and inspected prior to re-energization. All applicable lock out and tag out procedures must be followed.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

Required Parts

The LFI component PMMA surface characteristics are as follows

Cover Layer

Gloss

Scratch resistance

Weather resistance

Color Layer

Coloring

Ultraviolet resistance

Carrier Layer

Adhesion to backing foam

Heat deformation resistance

Backing Foam

Strength

Stability

Impact resistance

Heat deformation resistanceRepair Procedure

Illustration 1 g06509785

Simulated punch hole

Illustration 2 g06509787

Location to grind off backside

Grind material off from backside

Illustration 3 g06509788

Fiberglass mat and plastic filler

Place fiberglass mat and place plastic filler on backside

Illustration 4 g06509791

Location to grind off exterior side

Grind material off from exterior side

Illustration 5 g06509792

Location to add filler on exterior side

Fill hole on exterior side with plastic filler

Illustration 6 g06510059

Exterior surface to grind flat

Grind plastic filler on exterior to achieve flat surface

Illustration 7 g06510075

Area to apply plasticiser

Apply plastic filler with plasticiser to the exterior

Illustration 8 g06510079

Exterior area to grind plastic filler containing plasticiser

Grind plastic filler containing plasticiser and also area to be painted

Illustration 9 g06510084

Exterior plastic surface painted with primer

Paint exterior with primer for plastic surfaces

Illustration 10 g06510086

Exterior plastic surface painted with top coat

Paint exterior with top coat

Have questions with 101342-9070?

Group cross 101342-9070 ZEXEL

Toyo-Sha

Iseki

Daewoo

101342-9070

9 400 611 780

INJECTION-PUMP ASSEMBLY

3AB1

3AB1