Information injection-pump assembly

BOSCH

9 400 613 532

9400613532

ZEXEL

101342-0400

1013420400

ISUZU

8944660850

8944660850

Rating:

Service parts 101342-0400 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 532

9400613532

ZEXEL

101342-0400

1013420400

ISUZU

8944660850

8944660850

Zexel num

Bosch num

Firm num

Name

101342-0400

9 400 613 532

8944660850 ISUZU

INJECTION-PUMP ASSEMBLY

3AB1 K 14BA INJECTION PUMP ASSY PE1A,2A,3A PE

3AB1 K 14BA INJECTION PUMP ASSY PE1A,2A,3A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Injection quantity adjustment

Adjusting point

B

Rack position

12.2

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

43

42

44

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.6+-0.5

Pump speed

r/min

475

475

475

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

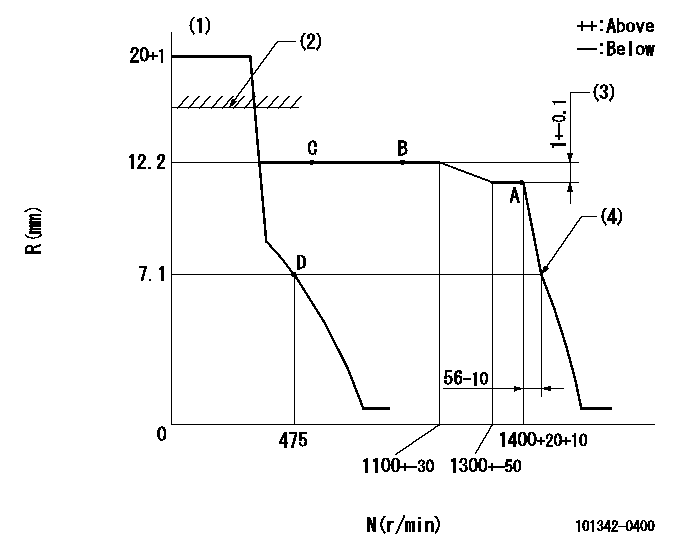

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK CAP: R1

(3)Rack difference between N = N1 and N = N2

(4)Idle sub spring setting: L1.

----------

K=5 R1=(17.5)mm N1=1400r/min N2=900r/min L1=6.9-0.2mm

----------

----------

K=5 R1=(17.5)mm N1=1400r/min N2=900r/min L1=6.9-0.2mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=25deg+-5deg

----------

----------

a=9deg+-5deg b=25deg+-5deg

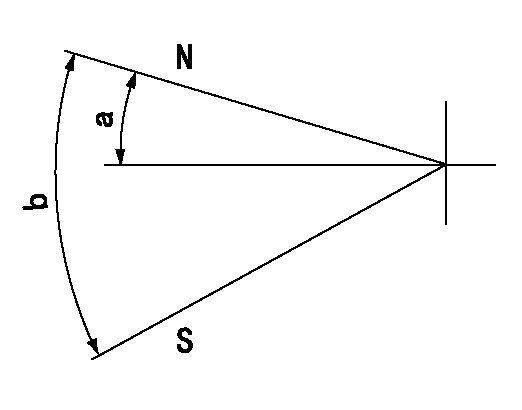

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Z' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(120deg)

----------

aa=18deg

----------

a=(120deg)

Information:

Solution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Note: Only perform these troubleshooting steps when the DEF tank is fully thawed and there is no remaining ice crystals/slush in the tank.Note: If any of the troubleshooting indicates the replacement of the DEF manifold, do not replace the DEF manifold. Repair the DEF manifold using the DEF manifold sensor kit.

Use the electronic service tool to download a full Product Status Report (PSR) (including all histograms and histories) before performing any troubleshooting.

Review the PSR to determine which code/events recorded have led to the activation SCR inducement codes:Note: Check the "Aftertreatment Abnormal Shutdown History" for Hot/Cold Shutdown events which may have occurred prior to the current inducement situation and may be an indication the system was incorrectly shut down previously.

A Cold Shutdown is recorded when the ambient temp is below −5° C (23° F) and the system has not completed the cooldown and system purge during the previous key-cycle.

Only investigate a logged 1235-9 (5856-9) code if the code has occurred less than 5 hours prior to the current diagnostic clock value. If the code is not persistent, the code is likely to be generated by either old engine software or a power supply dropping below the min supply voltage. If the code is showing a persistent triggering when on the latest engine software, this condition would indicate a hardware/connection issue.

DEF level codes (1761-xx/E954) are not to be considered a sign of DEF Manifold hardware failure (especially when in low ambient temperatures) unless the codes remain persistent after a tank fill. If there is another code present such as 1761-2/3130-2 (DEF level – Erratic) or 5392-31/E1370 (DEF Loss of Prime), this condition would indicate a system level issue, or the DEF tank has recently been fully drained down for an extended period and may require time for any DEF deposits to dissolve before level readings stabilize.

The order of troubleshooting codes should be SCR Inducement last, with DEF Tank Level codes second from last, always troubleshooting the DEF Volume Erratic (1761-2/3130-2) or DEF – Loss of Prime (5392-31/E1370) codes first.

Prior to beginning any troubleshooting of the codes reviewed in Step 2 and based on analysis, check that the coolant diverter valve is functioning correctly. Not allowing a small coolant flow to heat DEF tank fluid unintentionally above ambient temperature without triggering any codes, refer to Troubleshooting, DEF Tank Temperature Is High.

Ensure that the coolant flow direction is aligned with the flow direction arrow valve on the valve body. Refer to Step 3civ.

Record the ambient air temperature and DEF tank fluid temperature prior to starting the engine. Use these temperature readings as the reference for determining a temperature increase after warming the engine at idle. Refer to Step6.Note: As DEF is used as the

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Note: Only perform these troubleshooting steps when the DEF tank is fully thawed and there is no remaining ice crystals/slush in the tank.Note: If any of the troubleshooting indicates the replacement of the DEF manifold, do not replace the DEF manifold. Repair the DEF manifold using the DEF manifold sensor kit.

Use the electronic service tool to download a full Product Status Report (PSR) (including all histograms and histories) before performing any troubleshooting.

Review the PSR to determine which code/events recorded have led to the activation SCR inducement codes:Note: Check the "Aftertreatment Abnormal Shutdown History" for Hot/Cold Shutdown events which may have occurred prior to the current inducement situation and may be an indication the system was incorrectly shut down previously.

A Cold Shutdown is recorded when the ambient temp is below −5° C (23° F) and the system has not completed the cooldown and system purge during the previous key-cycle.

Only investigate a logged 1235-9 (5856-9) code if the code has occurred less than 5 hours prior to the current diagnostic clock value. If the code is not persistent, the code is likely to be generated by either old engine software or a power supply dropping below the min supply voltage. If the code is showing a persistent triggering when on the latest engine software, this condition would indicate a hardware/connection issue.

DEF level codes (1761-xx/E954) are not to be considered a sign of DEF Manifold hardware failure (especially when in low ambient temperatures) unless the codes remain persistent after a tank fill. If there is another code present such as 1761-2/3130-2 (DEF level – Erratic) or 5392-31/E1370 (DEF Loss of Prime), this condition would indicate a system level issue, or the DEF tank has recently been fully drained down for an extended period and may require time for any DEF deposits to dissolve before level readings stabilize.

The order of troubleshooting codes should be SCR Inducement last, with DEF Tank Level codes second from last, always troubleshooting the DEF Volume Erratic (1761-2/3130-2) or DEF – Loss of Prime (5392-31/E1370) codes first.

Prior to beginning any troubleshooting of the codes reviewed in Step 2 and based on analysis, check that the coolant diverter valve is functioning correctly. Not allowing a small coolant flow to heat DEF tank fluid unintentionally above ambient temperature without triggering any codes, refer to Troubleshooting, DEF Tank Temperature Is High.

Ensure that the coolant flow direction is aligned with the flow direction arrow valve on the valve body. Refer to Step 3civ.

Record the ambient air temperature and DEF tank fluid temperature prior to starting the engine. Use these temperature readings as the reference for determining a temperature increase after warming the engine at idle. Refer to Step6.Note: As DEF is used as the

Have questions with 101342-0400?

Group cross 101342-0400 ZEXEL

Isuzu

101342-0400

9 400 613 532

8944660850

INJECTION-PUMP ASSEMBLY

3AB1

3AB1