Information injection-pump assembly

BOSCH

9 400 613 531

9400613531

ZEXEL

101342-0390

1013420390

ISUZU

8944681320

8944681320

Rating:

Service parts 101342-0390 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

11.8(120)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 531

9400613531

ZEXEL

101342-0390

1013420390

ISUZU

8944681320

8944681320

Zexel num

Bosch num

Firm num

Name

101342-0390

9 400 613 531

8944681320 ISUZU

INJECTION-PUMP ASSEMBLY

3AB1 * K 14BA PE1A,2A,3A PE

3AB1 * K 14BA PE1A,2A,3A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.7

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

43

42.2

43.8

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.1

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

13.1

12.2

14

Max. variation between cylinders

%

0

-8

8

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.1+-0.5

Pump speed

r/min

475

475

475

Average injection quantity

mm3/st.

6

5

7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Test data Ex:

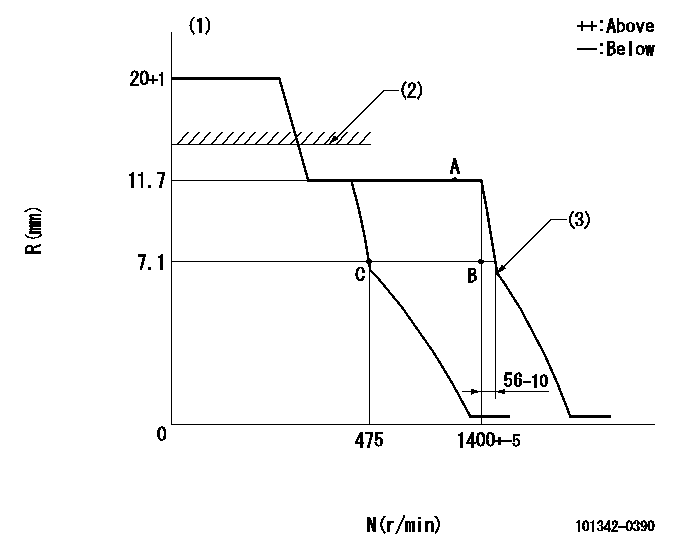

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Idle sub spring setting: L1.

----------

K=3 RAL=(17.5)mm L1=6.9-0.2mm

----------

----------

K=3 RAL=(17.5)mm L1=6.9-0.2mm

----------

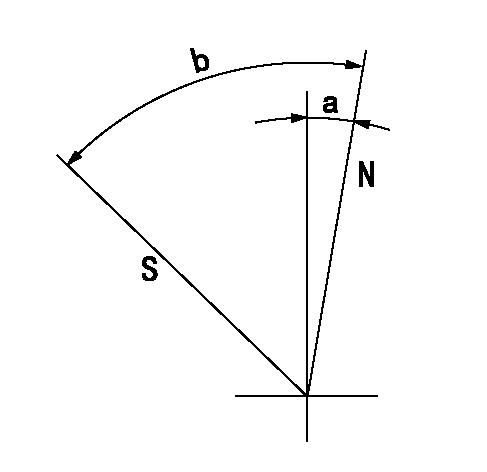

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=28.5deg+-5deg

----------

----------

a=10deg+-5deg b=28.5deg+-5deg

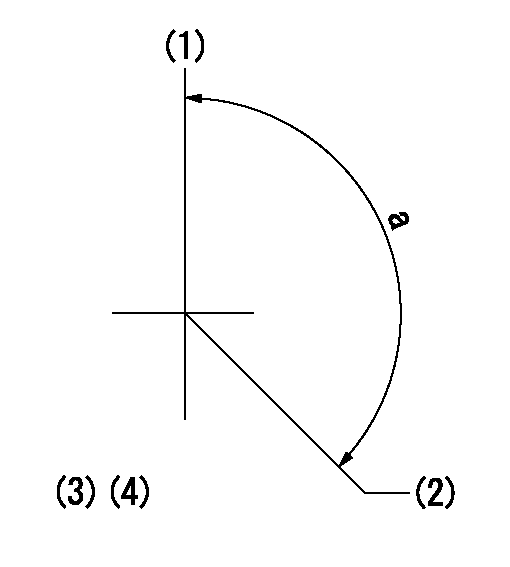

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=2.5deg+-5deg b=53deg+-5deg

----------

----------

a=2.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Z' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(120deg)

----------

aa=18deg

----------

a=(120deg)

Information:

Table 1

Item 3408C / 3412C 3176B 3176C / 3196

Connector P14 P1 P1

(-) Battery Pin-21 Pin-5 Pin-5

(+) 8 VDC Pin-10 Pin-35 Pin-35

Cat Data (+) Pin-9 Pin-9 Pin-9

Cat Data (-) Pin-19 Pin-3 Pin-3

Illustration 1 g06449052

(A) Port ECM

(B) Cat Link Booster

(C) EVIM

(D) STBD ECM

(E) CAT Link Booster

(F) Engine Vision Display

Illustration 2 g06449056

(G) Connector A

(H) Connector B

Turn the power OFF to the engine ECM and display unit.

Remove the ECM connector-battery pin and reinsert it into pin-3 on the 4-pin DT connector B (2).

Remove the ECM connector +8 VDC pin and reinsert into pin-4 on the 4-pin DT connector B (2).

Remove the ECM connector (CAT Data+) pin and reinsert into pin-1 on the 4-pin DT connector B (2).

Remove the ECM connector (Cat Data-) pin and reinsert into pin-2 on the 4-pin DT connector B (2).

Insert the BLACK wire into the ECM connector-battery pin.

Insert the PINK wire into the ECM connector CAT Data+ pin.

Insert the WHITE wire into the ECM connector CAT Data- pin.

Insert the RED wire into the ECM connector +8 VDC supply pin.

Plug connector B (2) into connector A (1).

Apply power to the ECM.

Have questions with 101342-0390?

Group cross 101342-0390 ZEXEL

Isuzu

101342-0390

9 400 613 531

8944681320

INJECTION-PUMP ASSEMBLY

3AB1

3AB1