Information injection-pump assembly

ZEXEL

101341-0001

1013410001

ISUZU

8943423221

8943423221

Rating:

Cross reference number

ZEXEL

101341-0001

1013410001

ISUZU

8943423221

8943423221

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-2

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.7

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

42.3

41.5

43.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.6+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1250

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

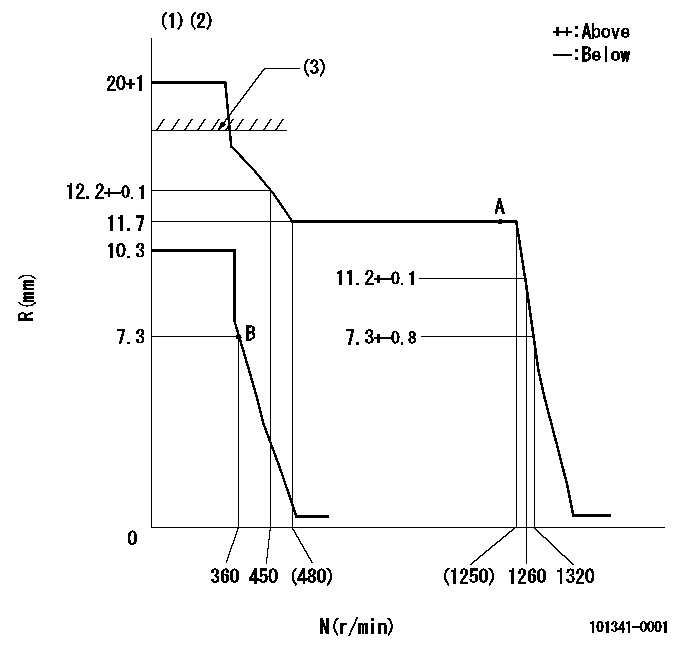

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK CAP: R1

----------

K=18 R1=(17.5)mm

----------

----------

K=18 R1=(17.5)mm

----------

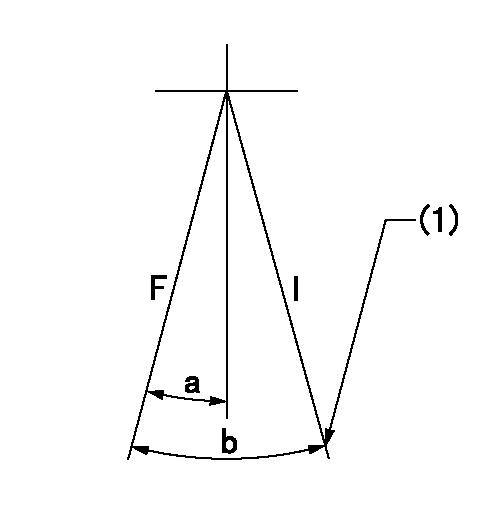

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(19deg)+-5deg b=(27deg)+-5deg

----------

----------

a=(19deg)+-5deg b=(27deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Z' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(120deg)

----------

aa=16deg

----------

a=(120deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

If the engine is stored for 6 months or more, the fuel injection pump linkage needs to be lubricated.Solution

Follow the procedure in this article to lubricate the fuel injection pump linkage.

Remove the fuel shutoff solenoid. Refer to Disassembly and Assembly, "Fuel Shutoff Solenoid - Remove and Install" for the correct procedure.

Spray the fuel control rack with a suitable lubricant spray.

Use a suitable magnet to operate the fuel control rack. The operation of the fuel control rack will disperse the lubricant.Note: If the fuel control rack does not move freely, then the fuel injection pump should be replaced. Refer to Disassembly and Assembly, "Fuel Injection Pump - Remove and Install" for the correct procedure.

Install the fuel shutoff solenoid. Refer to Disassembly and Assembly, "Fuel Shutoff Solenoid - Remove and Install" for the correct procedure.

Record the repair in the Service Information Management System (SIMSi), including the engine/machine serial number and the date of the repair.

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

If the engine is stored for 6 months or more, the fuel injection pump linkage needs to be lubricated.Solution

Follow the procedure in this article to lubricate the fuel injection pump linkage.

Remove the fuel shutoff solenoid. Refer to Disassembly and Assembly, "Fuel Shutoff Solenoid - Remove and Install" for the correct procedure.

Spray the fuel control rack with a suitable lubricant spray.

Use a suitable magnet to operate the fuel control rack. The operation of the fuel control rack will disperse the lubricant.Note: If the fuel control rack does not move freely, then the fuel injection pump should be replaced. Refer to Disassembly and Assembly, "Fuel Injection Pump - Remove and Install" for the correct procedure.

Install the fuel shutoff solenoid. Refer to Disassembly and Assembly, "Fuel Shutoff Solenoid - Remove and Install" for the correct procedure.

Record the repair in the Service Information Management System (SIMSi), including the engine/machine serial number and the date of the repair.