Information injection-pump assembly

BOSCH

9 400 613 524

9400613524

ZEXEL

101322-0240

1013220240

ISUZU

8941372900

8941372900

Rating:

Include in #1:

106871-8991

as _

Cross reference number

BOSCH

9 400 613 524

9400613524

ZEXEL

101322-0240

1013220240

ISUZU

8941372900

8941372900

Zexel num

Bosch num

Firm num

Name

101322-0240

9 400 613 524

8941372900 ISUZU

INJECTION-PUMP ASSEMBLY

3AD1 * K

3AD1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-2

Pre-stroke

mm

1.75

1.7

1.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

31.9

30.9

32.9

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.2+-0.5

Pump speed

r/min

385

385

385

Average injection quantity

mm3/st.

8

6.9

9.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

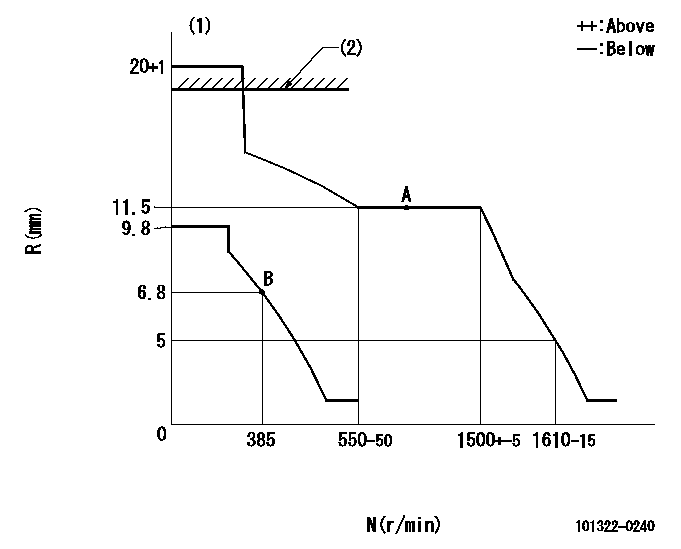

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)At rack cap installation: R1

----------

K=7 R1=(17.5)mm

----------

----------

K=7 R1=(17.5)mm

----------

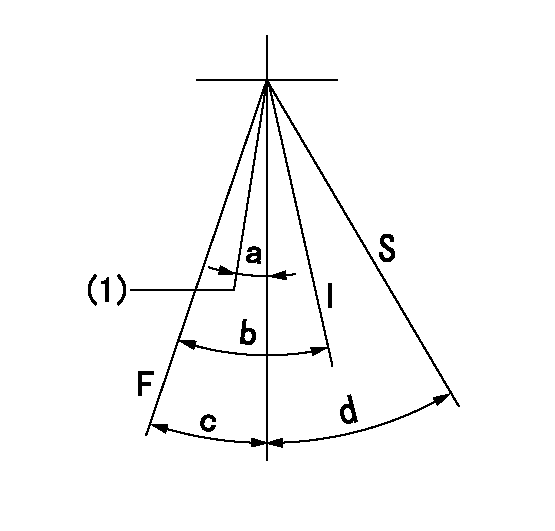

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Cancel spring dead point

----------

----------

a=6deg b=30deg+-5deg c=16deg+-5deg d=32deg+-3deg

----------

----------

a=6deg b=30deg+-5deg c=16deg+-5deg d=32deg+-3deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'Z' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=24deg

----------

a=(120deg)

----------

aa=24deg

----------

a=(120deg)

Information:

Tooling, Test, and Bulk Ground Fill Support Equipment

Diesel Exhaust Fluid (DEF)

Two container sizes of DEF are available through the Cat® dealers in North America. DEF must meet ISO 22241-1 specifications.

Table 1

Tool Part Number Description

350-8733 Diesel Exhaust Fluid 9.5 L (2.5 US gal) bottle

350-8734 Diesel Exhaust Fluid 1378 L (364 US gal) tote

443-0955 Removal Tool DEF filter removal tool Dispensing Equipment

Three different dispensing kits are offered to protect DEF quality. Optional flow meter and coupler are also available.

Table 2

Tool Part Number Description

422-1185 Pump Adapter (DEF DISPENSER) 12 V dispenser unit

423-7843 Pump Adapter (DEF DISPENSER) 110 V dispenser unit

423-7844 Pump Adapter (DEF DISPENSER) 230 V dispenser unit with"smart start"tote base

423-7795 Flow Meter In line DEF flow meter

423-7799 Coupler MicroMatic coupler Dispenser Unit Repair Parts

Table 3

Tool Part Number Description

436-6643 Repair Kit 12 V dispenser unit

436-6646 Diesel Exhaust Fluid Pump 12 V repair group

436-6642 Hose 20'/4'

436-6644 Swivel

436-6645 Repair Kit 1/2 hp pump

436-6647 Nozzle (DIESEL EXHAUST FLUID) Dispensing nozzle Storage and Transportation

Preventing DEF contamination does not stop at the pump. Protect your DEF supply with climate-specific enclosures and transportation tanks.

Table 4

Part Number Description

435-8671 Dispenser Warm-weather enclosure

435-8672 Dispenser Cold-weather enclosure

460-4077 Tank 121 L (32 US gal)

460-4078 Tank 269 L (71 US gal) Fast Fill Vehicle Interface

Illustration 1 g06516654

584-9979 Nozzle As

Table 5

584-9979 Nozzle As

Repair parts for 584-9979 Nozzle As

- 587-3371 Rear Cap

- 587-3372 Handle

- 587-3373 Hose (3/4")

- 587-3374 O-Ring Seal

- 587-3375 Handle (optional)

459-9296 Receiver As (Permanently mounted on vehicle)

For heated DEF hose repair connectors, kits, and instructions , refer to Service Magazine, M0103829, "Repair Kits for Quick Connect Diesel Exhaust Fluid (DEF) Line Fittings Are Now Available for Certain Cat® Machine Engines". Testing Equipment

Test your DEF supply and DEF injector with DEF-specific testing equipment. Complete kits or individual testing components are available for your needs.

Table 6

441-0451 Tool Gp (includes hard case, foam insert, and hardware)

- 441-0454 Container

- 443-7055 Test Kit

- 398-4985 Probe

- 398-4987 Probe

- 398-5080 Lead

- 398-5081 Lead

- 398-5083 Plug

450-1515 Tool Gp (DIESEL EXHAUST FLUID) (includes hard case, foam insert, and hardware)

- 441-0454 Container

- 398-4985 Probe

- 398-4987 Probe

- 398-5080 Lead

- 398-5081 Lead

- 398-5083 Plug

441-0454 Container

443-7055 Test Kit

431-7087 Tool Gp (REFRACTOMETER (DEF))

360-0774 Refractometer

372-5260 Test Lead Tool Group

576-6134 Test Strip

Diesel Exhaust Fluid (DEF)

Two container sizes of DEF are available through the Cat® dealers in North America. DEF must meet ISO 22241-1 specifications.

Table 1

Tool Part Number Description

350-8733 Diesel Exhaust Fluid 9.5 L (2.5 US gal) bottle

350-8734 Diesel Exhaust Fluid 1378 L (364 US gal) tote

443-0955 Removal Tool DEF filter removal tool Dispensing Equipment

Three different dispensing kits are offered to protect DEF quality. Optional flow meter and coupler are also available.

Table 2

Tool Part Number Description

422-1185 Pump Adapter (DEF DISPENSER) 12 V dispenser unit

423-7843 Pump Adapter (DEF DISPENSER) 110 V dispenser unit

423-7844 Pump Adapter (DEF DISPENSER) 230 V dispenser unit with"smart start"tote base

423-7795 Flow Meter In line DEF flow meter

423-7799 Coupler MicroMatic coupler Dispenser Unit Repair Parts

Table 3

Tool Part Number Description

436-6643 Repair Kit 12 V dispenser unit

436-6646 Diesel Exhaust Fluid Pump 12 V repair group

436-6642 Hose 20'/4'

436-6644 Swivel

436-6645 Repair Kit 1/2 hp pump

436-6647 Nozzle (DIESEL EXHAUST FLUID) Dispensing nozzle Storage and Transportation

Preventing DEF contamination does not stop at the pump. Protect your DEF supply with climate-specific enclosures and transportation tanks.

Table 4

Part Number Description

435-8671 Dispenser Warm-weather enclosure

435-8672 Dispenser Cold-weather enclosure

460-4077 Tank 121 L (32 US gal)

460-4078 Tank 269 L (71 US gal) Fast Fill Vehicle Interface

Illustration 1 g06516654

584-9979 Nozzle As

Table 5

584-9979 Nozzle As

Repair parts for 584-9979 Nozzle As

- 587-3371 Rear Cap

- 587-3372 Handle

- 587-3373 Hose (3/4")

- 587-3374 O-Ring Seal

- 587-3375 Handle (optional)

459-9296 Receiver As (Permanently mounted on vehicle)

For heated DEF hose repair connectors, kits, and instructions , refer to Service Magazine, M0103829, "Repair Kits for Quick Connect Diesel Exhaust Fluid (DEF) Line Fittings Are Now Available for Certain Cat® Machine Engines". Testing Equipment

Test your DEF supply and DEF injector with DEF-specific testing equipment. Complete kits or individual testing components are available for your needs.

Table 6

441-0451 Tool Gp (includes hard case, foam insert, and hardware)

- 441-0454 Container

- 443-7055 Test Kit

- 398-4985 Probe

- 398-4987 Probe

- 398-5080 Lead

- 398-5081 Lead

- 398-5083 Plug

450-1515 Tool Gp (DIESEL EXHAUST FLUID) (includes hard case, foam insert, and hardware)

- 441-0454 Container

- 398-4985 Probe

- 398-4987 Probe

- 398-5080 Lead

- 398-5081 Lead

- 398-5083 Plug

441-0454 Container

443-7055 Test Kit

431-7087 Tool Gp (REFRACTOMETER (DEF))

360-0774 Refractometer

372-5260 Test Lead Tool Group

576-6134 Test Strip

Have questions with 101322-0240?

Group cross 101322-0240 ZEXEL

Isuzu

101322-0240

9 400 613 524

8941372900

INJECTION-PUMP ASSEMBLY

3AD1

3AD1