Information injection-pump assembly

BOSCH

F 019 Z10 921

f019z10921

ZEXEL

101302-9020

1013029020

Rating:

Include in #1:

106871-8940

as _

Cross reference number

BOSCH

F 019 Z10 921

f019z10921

ZEXEL

101302-9020

1013029020

Zexel num

Bosch num

Firm num

Name

101302-9020

F 019 Z10 921

DPICO

INJECTION-PUMP ASSEMBLY

3D100-AT Q

3D100-AT Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-1420

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-2

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 2

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

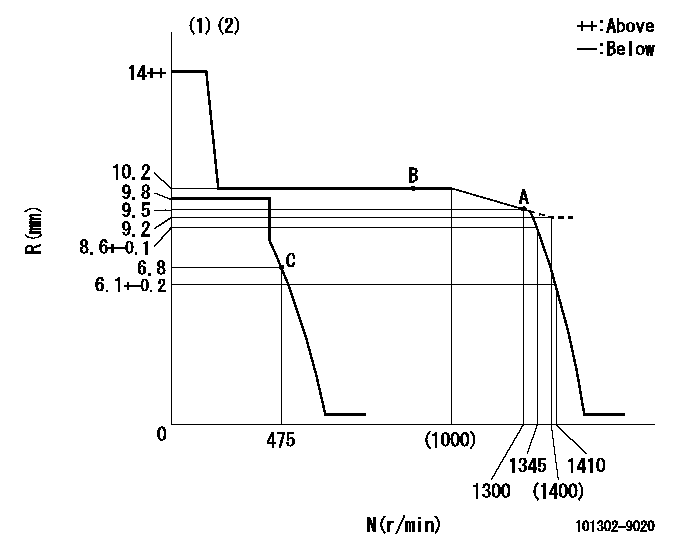

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

46.2

45.2

47.2

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.2+-0.5

Pump speed

r/min

475

475

475

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

----------

K=10

----------

----------

K=10

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(14deg)+-5deg b=(34deg)+-5deg

----------

----------

a=(14deg)+-5deg b=(34deg)+-5deg

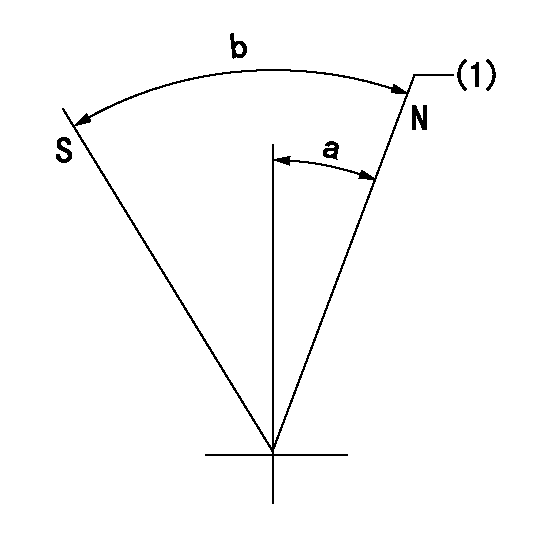

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=15deg+-5deg b=53deg+-5deg

----------

----------

a=15deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'B' at the No 3 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=17deg

----------

a=(100deg)

----------

aa=17deg

----------

a=(100deg)

Information:

Cat Data Logging and Alarm System (DLAS) 300

The Cat DPF system requires a Cat Data Logging and Alarm System (DLAS). The Cat DLAS measures and records exhaust temperature and backpressure. These parameters are essential in determining whether the application duty cycle is acceptable for the filter. There are also a series of alarms to help the user in case a problem occurs.Establishing an Ethernet Connection

Connect a laptop or other computer to the DLAS300 using an ethernet cable. The ethernet cable is also referred to as a LAN or network cable.

Verify that the green link light on the ethernet connector is on.

Wait for Windows to configure the network.

Start Internet Explorer, Firefox, Chrome or another web browser on the laptop.

Enter dlas300 or 169.254.1.1 into the address bar of the web browser. The web page should begin to display within a few seconds.

If the page cannot be found, or if a different web page is displayed, refer to network troubleshooting.To communicate with the DLAS300, the ethernet adapter on the laptop must be configured with an IP address on the 169.254.0.0/16 network. If the laptop is configured to use DHCP but cannot find a DHCP server, Windows will use Automatic Private IP Addressing (APIPA) to choose an IP address on the 169.254.0.0/16 network.An alternate solution is to configure the Internet Protocol (TCP/IP) Properties with a static IP address. To configure a static IP address, follow the steps below:

Open "Network Connections" from the control panel and change the settings of the ethernet connection. Ethernet connection is often called Local Area Connection.

From the "Properties" dialog box, select "Internet Protocol" (TCP/IP) and click "Properties".

The 169.254.2.1 address is a suggestion.

Any IP address other than 169.254.1.1 or the DLAS300 address can be used.web Browser Proxy Settings

The web browser may be configured with proxy settings that prevent accessing the DLAS300. To disable the proxy settings for Internet Explorer or other browsers, follow the steps below:

Open the "Internet Options" dialog box.

Open the dialog box from either the tools menu of Internet Explorer or from the control panel.

Select the "Connections" tab and click the "LAN settings" button.

On the "Local Area Network (LAN) Settings" dialog box, de-select everything.Downloading Data

The logged data can be copied to a USB flash drive or downloaded through the web interface. The resulting data file is in comma-separated value (CSV) format for easy import into Microsoft Excel or other data analysis software. The first two lines of the file contain the engine name, engine serial number, catalyst serial number, and initial performance test results.To copy the logged data to a USB flash drive, perform the following steps:

Insert the USB flash drive into the USB port on the front panel.

Press and release the front panel button.

Monitor the activity light on the USB flash drive. The transfer is complete when no activity is indicated for more than 5 seconds. If the USB flash drive does not have an activity light, wait at least 5 minutes to ensure that all data has been copied.

Remove the USB flash driveCopying may take

The Cat DPF system requires a Cat Data Logging and Alarm System (DLAS). The Cat DLAS measures and records exhaust temperature and backpressure. These parameters are essential in determining whether the application duty cycle is acceptable for the filter. There are also a series of alarms to help the user in case a problem occurs.Establishing an Ethernet Connection

Connect a laptop or other computer to the DLAS300 using an ethernet cable. The ethernet cable is also referred to as a LAN or network cable.

Verify that the green link light on the ethernet connector is on.

Wait for Windows to configure the network.

Start Internet Explorer, Firefox, Chrome or another web browser on the laptop.

Enter dlas300 or 169.254.1.1 into the address bar of the web browser. The web page should begin to display within a few seconds.

If the page cannot be found, or if a different web page is displayed, refer to network troubleshooting.To communicate with the DLAS300, the ethernet adapter on the laptop must be configured with an IP address on the 169.254.0.0/16 network. If the laptop is configured to use DHCP but cannot find a DHCP server, Windows will use Automatic Private IP Addressing (APIPA) to choose an IP address on the 169.254.0.0/16 network.An alternate solution is to configure the Internet Protocol (TCP/IP) Properties with a static IP address. To configure a static IP address, follow the steps below:

Open "Network Connections" from the control panel and change the settings of the ethernet connection. Ethernet connection is often called Local Area Connection.

From the "Properties" dialog box, select "Internet Protocol" (TCP/IP) and click "Properties".

The 169.254.2.1 address is a suggestion.

Any IP address other than 169.254.1.1 or the DLAS300 address can be used.web Browser Proxy Settings

The web browser may be configured with proxy settings that prevent accessing the DLAS300. To disable the proxy settings for Internet Explorer or other browsers, follow the steps below:

Open the "Internet Options" dialog box.

Open the dialog box from either the tools menu of Internet Explorer or from the control panel.

Select the "Connections" tab and click the "LAN settings" button.

On the "Local Area Network (LAN) Settings" dialog box, de-select everything.Downloading Data

The logged data can be copied to a USB flash drive or downloaded through the web interface. The resulting data file is in comma-separated value (CSV) format for easy import into Microsoft Excel or other data analysis software. The first two lines of the file contain the engine name, engine serial number, catalyst serial number, and initial performance test results.To copy the logged data to a USB flash drive, perform the following steps:

Insert the USB flash drive into the USB port on the front panel.

Press and release the front panel button.

Monitor the activity light on the USB flash drive. The transfer is complete when no activity is indicated for more than 5 seconds. If the USB flash drive does not have an activity light, wait at least 5 minutes to ensure that all data has been copied.

Remove the USB flash driveCopying may take

Have questions with 101302-9020?

Group cross 101302-9020 ZEXEL

Dpico

101302-9020

F 019 Z10 921

INJECTION-PUMP ASSEMBLY

3D100-AT

3D100-AT