Information injection-pump assembly

BOSCH

9 400 613 523

9400613523

ZEXEL

101272-3010

1012723010

KOMATSU

6142751205

6142751205

Rating:

Service parts 101272-3010 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 523

9400613523

ZEXEL

101272-3010

1012723010

KOMATSU

6142751205

6142751205

Zexel num

Bosch num

Firm num

Name

101272-3010

9 400 613 523

6142751205 KOMATSU

INJECTION-PUMP ASSEMBLY

2D94 * K

2D94 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

39

38

40

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.8

8

9.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

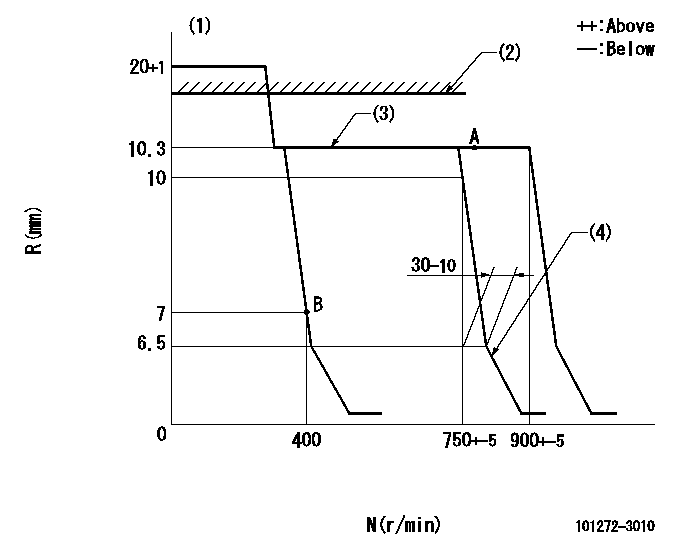

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK CAP: R1

(3)Idle spring not operating.

(4)Idle sub spring setting: L1.

----------

K=12 R1=(18)mm L1=6.5-0.5mm

----------

----------

K=12 R1=(18)mm L1=6.5-0.5mm

----------

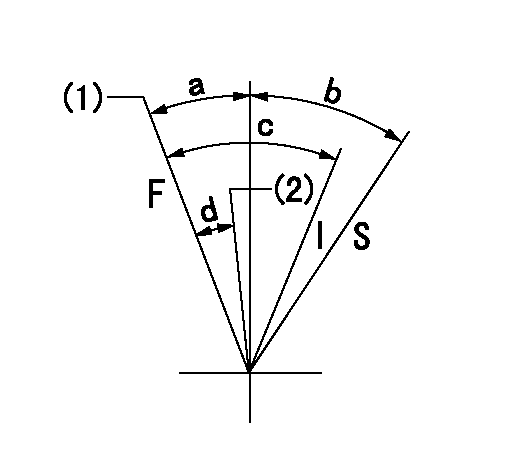

Speed control lever angle

I:Idle

S:Stop

(1)Set the pump speed at aa. ( At delivery )

(2)Pump speed = bb

----------

aa=900r/min bb=750r/min

----------

a=10deg+-5deg b=32deg+-3deg c=24deg+-5deg d=7deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=10deg+-5deg b=32deg+-3deg c=24deg+-5deg d=7deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of camshaft's key groove at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Ensure that all components are free of contaminants before installing. Contaminants may cause premature wear and reduced component service life.

Note: Disposition and Recycling - Common components of exhaust aftertreatment devices include, but are not limited to, cordierite, silicon carbide, iron zeolite, vanadium, platinum, and palladium. After the devices are used in an engine exhaust flow they can include some by-products that result from combustion. Follow applicable Federal, State, and local regulations when handling or discarding used aftertreatment devices

Illustration 1 g03842051

Note: Prior to removal of the catalyst, identify the position of the catalysts and airflow direction. Ensure that the catalyst part number position and the air flow direction remain the same.

Remove Diesel Particulate Filter (DPF) hatch cover (1) nuts, bolts, and washers.

Remove hatch cover (1) from the reactor unit.

Remove gasket assembly from the sealing surface of the hatch cover.

Carefully remove DPF catalyst assembly by removing the V band clamps. If necessary, repeat for other PDF catalysts. Take note of DPF air flow direction and location for reassembly.

Carefully install DPF catalyst into the cabinet with new gaskets. Verify correct position and air flow direction of the DPF.

DPF should always be installed in the direction shown in illustration 1. The long end of the DPF should be installed in the sleeve of the reactor and secured with the proper V band clamps.

For verified applications, replacement DPFs must have the proper tags and meet all documentation requirements.

Apply final torque to V band clamps. Refer to Specifications, SENR3130, "Torque Specifications" for the proper torque.

Replace all inner backing strip gaskets on the DPF catalyst cover.

Install DPF cover assembly.

Replace all damaged bolts.

Apply final torque to all bolts in a circular pattern. Refer to Specifications, SENR3130, "Torque Specifications" for the proper torque.

Verify that all bolts are at the proper torque value.

Have questions with 101272-3010?

Group cross 101272-3010 ZEXEL

Komatsu

101272-3010

9 400 613 523

6142751205

INJECTION-PUMP ASSEMBLY

2D94

2D94