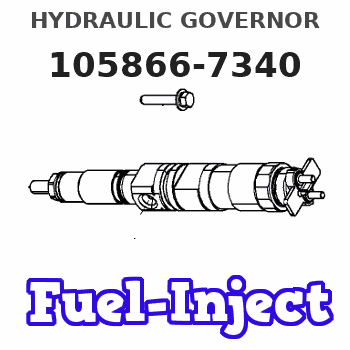

Information hydraulic governor

BOSCH

F 019 Z2E 518

f019z2e518

ZEXEL

105866-7340

1058667340

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 105866-7340 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1. | [1] | 158502-0420 | BASE |

| 2. | [1] | 029811-8000 | BEARING PLATE |

| 3. | [1] | 158528-0900 | PACKING RING |

| 7. | [1] | 158131-0100 | GEAR SHAFT |

| 10. | [1] | 158028-0000 | O-RING |

| 11. | [1] | 158507-1920 | DIAPHRAGM HOUSING |

| 13. | [1] | 158621-0600 | SLIDING PIECE |

| 18. | [1] | 158699-0621 | COMPENSATOR ASSY |

| 18/1. | [1] | 158610-1101 | POWER PISTON |

| 18/3. | [1] | 158654-0800 | COILED SPRING |

| 18/4. | [1] | 158614-0700 | STOP PIN |

| 18/5. | [1] | 158612-0500 | PLAIN WASHER |

| 18/6. | [1] | 158654-0900 | COILED SPRING |

| 18/7. | [1] | 016110-1220 | LOCKING WASHER |

| 18/8. | [1] | 158612-0401 | BUSHING |

| 18/9. | [2] | 016550-2310 | O-RING |

| 18/10. | [1] | 158615-0500 | PUMP PLUNGER |

| 18/11. | [1] | 025620-1410 | SPRING PIN |

| 35. | [3] | 029330-6070 | GASKET |

| 36. | [3] | 010206-2520 | HEX-SOCKET-HEAD CAP SCREW |

| 50. | [1] | 158600-0720 | FLYWEIGHT ASSEMBLY |

| 51. | [1] | 158106-0100 | PLAIN WASHER |

| 52. | [1] | 029811-0000 | BEARING PLATE |

| 53. | [1] | 158620-1120 | PILOT VALVE |

| 60. | [2] | 158220-0000 | GUIDE LEVER |

| 61. | [2] | 158736-0200 | BEARING PIN |

| 62. | [4] | 025520-1510 | SPLIT PIN |

| 70. | [1] | 158730-0220 | TERMINAL ARM |

| 70/1. | [1] | 158230-0020 | TERMINAL ARM |

| 70/2. | [1] | 158315-0200 | TERMINAL SHAFT |

| 70/3. | [1] | 158315-0200 | TERMINAL SHAFT |

| 70/4. | [2] | 158736-0100 | TAPER PIN |

| 70/5. | [2] | 011006-0620 | SET OF NUTS |

| 70/6. | [1] | 158214-0020 | SPEED DROOP ADJUSTER |

| 70/7. | [1] | 014020-5120 | PLAIN WASHER |

| 70/8. | [1] | 029320-5030 | TAB WASHER |

| 70/9. | [1] | 010535-1220 | FLAT-HEAD SCREW |

| 85. | [1] | 158814-1200 | SPEED CONTROL SHAFT |

| 86. | [1] | 158823-0300 | BUSHING |

| 87. | [1] | 158322-0200 | COILED SPRING |

| 88. | [1] | 158710-0400 | STRAP |

| 89. | [1] | 029404-5010 | BEARING PIN |

| 91. | [1] | 158712-2000 | CONTROL LEVER |

| 93. | [1] | 029010-5210 | BLEEDER SCREW |

| 95. | [1] | 158211-0100 | STRAP |

| 96. | [2] | 158653-0100 | WIRE |

| 104. | [1] | 158017-0900 | GASKET |

| 105. | [1] | 158964-2120 | GOVERNOR MOTOR ASSY |

| 105/1. | [1] | 158964-1411 | CASE |

| 105/2. | [1] | 158903-0200 | HOLDER |

| 105/3. | [1] | 158903-0300 | HOLDER |

| 105/4. | [1] | 158903-0400 | FLAT-HEAD SCREW |

| 105/5. | [1] | 158903-1720 | ADJUSTER |

| 105/6. | [2] | 158903-0800 | PLATE |

| 105/7. | [4] | 029010-6330 | BLEEDER SCREW M6P1.0L13 |

| 105/8. | [1] | 014020-8140 | PLAIN WASHER D16&8.5T1.2 |

| 105/9. | [1] | 158904-0500 | TOOTHED GEAR |

| 105/10. | [1] | 158590-0000 | BEARING PIN |

| 105/11. | [2] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 105/14. | [1] | 158904-0300 | LEVER SHAFT |

| 105/15. | [1] | 158904-0200 | LEVER SHAFT |

| 105/16. | [3] | 014020-8140 | PLAIN WASHER D16&8.5T1.2 |

| 105/16. | [3] | 014020-8140 | PLAIN WASHER D16&8.5T1.2 |

| 105/16. | [3] | 014020-8140 | PLAIN WASHER D16&8.5T1.2 |

| 105/17. | [3] | 015320-1540 | SPLIT PIN |

| 105/18. | [2] | 158904-0400 | TOOTHED GEAR |

| 105/18. | [2] | 158904-0400 | TOOTHED GEAR |

| 105/19. | [3] | 011005-0820 | SET OF NUTS |

| 105/19. | [3] | 011005-0820 | SET OF NUTS |

| 105/20. | [1] | 158904-1920 | ROUND NUT |

| 105/21. | [1] | 158916-0000 | SET OF NUTS |

| 105/27. | [1] | 158906-0700 | TERMINAL BOARD |

| 105/28. | [2] | 014020-4140 | PLAIN WASHER D8&4.5T0.5 |

| 105/29. | [2] | 014110-4440 | LOCKING WASHER |

| 105/30. | [2] | 012154-1640 | FLAT-HEAD SCREW |

| 105/31. | [1] | 158902-0300 | JOINT CONNECTION |

| 105/32. | [1] | 158902-0020 | FRICTION COUPLING |

| 105/34. | [1] | 158908-2800 | GEAR HEAD |

| 105/35. | [1] | 158901-7200 | MOTOR |

| 105/36. | [4] | 014020-4140 | PLAIN WASHER D8&4.5T0.5 |

| 105/37. | [4] | 158901-8100 | FLAT-HEAD SCREW |

| 105/38. | [1] | 158901-9700 | HOSE |

| 105/39. | [1] | 158901-9000 | COVER |

| 105/40. | [1] | 158900-0900 | BRACKET |

| 105/41. | [4] | 158900-0200 | BUSHING |

| 105/42. | [4] | 029010-6350 | BLEEDER SCREW M6P1.0L22 |

| 105/43. | [1] | 158907-1820 | LIMIT SWITCH |

| 105/44. | [1] | 158907-1720 | LIMIT SWITCH |

| 105/46. | [4] | 020144-1240 | BLEEDER SCREW |

| 105/47. | [1] | 158906-0801 | TERMINAL |

| 105/48. | [1] | 158562-2600 | COVER |

| 105/49. | [4] | 014020-6140 | PLAIN WASHER |

| 105/50. | [4] | 014110-6440 | LOCKING WASHER |

| 105/51. | [4] | 158909-0100 | BLEEDER SCREW |

| 105/52. | [1] | 158901-4400 | WIRE |

| 105/53. | [2] | 158901-2700 | PLAIN WASHER |

| 105/54. | [1] | 158901-2800 | PACKING |

| 105/55. | [1] | 158901-2600 | GROUND |

| 105/70. | [1] | 158563-1300 | COVER |

| 105/85. | [1] | 158901-9420 | COVER |

| 112. | [1] | 026512-1640 | GASKET D15.9&12.2T1 |

| 113. | [1] | 155406-0220 | AIR FILTER |

| 118. | [1] | 158527-0200 | NEEDLE VALVE |

| 119. | [1] | 016500-0710 | O-RING |

| 123. | [2] | 026512-1640 | GASKET D15.9&12.2T1 |

| 124. | [2] | 029111-2070 | CAPSULE M12P1.5L10 |

| 130. | [1] | 029331-8040 | GASKET |

| 131. | [1] | 158660-0320 | CONTROL VALVE |

| 135. | [1] | 158515-0900 | INDICATOR PLATE |

| 137. | [1] | 158515-1000 | INDICATOR PLATE |

| 140. | [2] | 158820-0620 | POINTER |

| 140. | [2] | 158820-0620 | POINTER |

| 142. | [2] | 158820-0620 | POINTER |

| 142. | [2] | 158820-0620 | POINTER |

| 163. | [1] | 010210-1420 | HEX-SOCKET-HEAD CAP SCREW |

| 164. | [1] | 026510-1340 | GASKET D13.4&10.2T1 |

| 190. | [1] | 158017-1000 | GASKET |

| 200. | [1] | 158599-7420 | SPARE PART |

Include in #2:

105866-7340

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Maintenance Recommendations

Caterpillar Inc. truck engines are certified by the United States Environmental Protection Agency (EPA) to comply with smoke and gaseous emission standards prescribed by Federal laws at the time of manufacture.Efficiency of emission control and engine performance depends on adherence to proper operation and maintenance recommendations AND use of recommended fuels and lubricating oils. It is recommended that major adjustments and repair be made by your authorized Caterpillar dealer.Various chemical fuel additives claiming to reduce visible smoke are available commercially. Although additives have been used by individuals to solve some isolated smoke problems in the field, they are not recommended for general use. Federal smoke regulations require that engines be certified without smoke depressants.The corrective steps taken immediately on discovery of worn parts, which may affect emission levels, will help assure proper operation of emission control systems. The use of genuine Caterpillar parts is recommended. Suppliers of non-Caterpillar parts must assure the owner that the use of such parts will not adversely affect emission levels.Regular maintenance intervals, along with special emphasis on the following items, are necessary to keep exhaust emissions within acceptable limits for the useful life of the engine. Refer to the Maintenance Section of this manual. If the engine is operating under severe conditions, adjust the maintenance schedule accordingly. See your authorized Caterpillar dealer to help analyze your specific application, operating environment and maintenance schedule adjustments.The following is an explanation of maintenance for emission-related components. See the Maintenance Schedule for the specific interval for the following items. ELECTRONIC UNIT INJECTORS - Fuel nozzles are subject to tip wear as a result of fuel contamination. This damage can cause an increase in fuel consumption, the engine to emit black smoke, misfire or run rough. Inspect and replace if necessary. Fuel injectors can be tested by an authorized Caterpillar truck engine dealer. TURBOCHARGER - Check for any unusual sound or vibration in the turbocharger. Inspect inlet and exhaust piping and connections. Check bearing condition and perform maintenance as described in the Maintenance Schedule. AIR/FUEL RATIO CONTROL - This component is a device to control the smoke emission of an engine during its operation when low inlet manifold pressure exists.Slow engine response and low power may indicate a need for adjustment or repair. Your Caterpillar dealer is equipped with the necessary tools, personnel and procedures to perform this service.Owner is encouraged to keep adequate maintenance records, but the absence of such, in and of itself, will not invalidate the warranty.The vehicle owner may perform routine maintenance, repairs and other non warranty work or have it done at any repair facility. Such non warranty work need not be performed at a designated warranty station in order for the warranty to remain in force.Customer Assistance-Emission Control Systems Warranty

Caterpillar Inc. aims to ensure that the Emission Control Systems warranty is properly administered. In the event that you do not receive the warranty service to which you believe you are entitled under the Emission Control Systems Warranty, call or write:Caterpillar Inc.

Manager,

Caterpillar Inc. truck engines are certified by the United States Environmental Protection Agency (EPA) to comply with smoke and gaseous emission standards prescribed by Federal laws at the time of manufacture.Efficiency of emission control and engine performance depends on adherence to proper operation and maintenance recommendations AND use of recommended fuels and lubricating oils. It is recommended that major adjustments and repair be made by your authorized Caterpillar dealer.Various chemical fuel additives claiming to reduce visible smoke are available commercially. Although additives have been used by individuals to solve some isolated smoke problems in the field, they are not recommended for general use. Federal smoke regulations require that engines be certified without smoke depressants.The corrective steps taken immediately on discovery of worn parts, which may affect emission levels, will help assure proper operation of emission control systems. The use of genuine Caterpillar parts is recommended. Suppliers of non-Caterpillar parts must assure the owner that the use of such parts will not adversely affect emission levels.Regular maintenance intervals, along with special emphasis on the following items, are necessary to keep exhaust emissions within acceptable limits for the useful life of the engine. Refer to the Maintenance Section of this manual. If the engine is operating under severe conditions, adjust the maintenance schedule accordingly. See your authorized Caterpillar dealer to help analyze your specific application, operating environment and maintenance schedule adjustments.The following is an explanation of maintenance for emission-related components. See the Maintenance Schedule for the specific interval for the following items. ELECTRONIC UNIT INJECTORS - Fuel nozzles are subject to tip wear as a result of fuel contamination. This damage can cause an increase in fuel consumption, the engine to emit black smoke, misfire or run rough. Inspect and replace if necessary. Fuel injectors can be tested by an authorized Caterpillar truck engine dealer. TURBOCHARGER - Check for any unusual sound or vibration in the turbocharger. Inspect inlet and exhaust piping and connections. Check bearing condition and perform maintenance as described in the Maintenance Schedule. AIR/FUEL RATIO CONTROL - This component is a device to control the smoke emission of an engine during its operation when low inlet manifold pressure exists.Slow engine response and low power may indicate a need for adjustment or repair. Your Caterpillar dealer is equipped with the necessary tools, personnel and procedures to perform this service.Owner is encouraged to keep adequate maintenance records, but the absence of such, in and of itself, will not invalidate the warranty.The vehicle owner may perform routine maintenance, repairs and other non warranty work or have it done at any repair facility. Such non warranty work need not be performed at a designated warranty station in order for the warranty to remain in force.Customer Assistance-Emission Control Systems Warranty

Caterpillar Inc. aims to ensure that the Emission Control Systems warranty is properly administered. In the event that you do not receive the warranty service to which you believe you are entitled under the Emission Control Systems Warranty, call or write:Caterpillar Inc.

Manager,