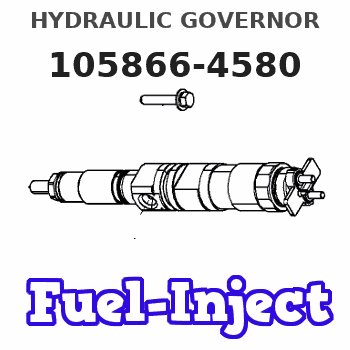

Information hydraulic governor

BOSCH

F 019 Z5E 226

f019z5e226

ZEXEL

105866-4580

1058664580

NIIGATA-TEKKOU

17720149A

17720149a

Rating:

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Caterpillar's Scheduled Oil Sampling (S O S) is the best indicator for determining what is happening inside your engine.S O S is a diagnostic tool used to determine oil performance and component wear rates with a series of tests designed to identify and measure contamination such as soot, sulfur, etc. and degradation such as the presence of fuel, water and antifreeze in a sample of oil.The tests also determine the amount of wear metals present in the oil sample, which is compared to established Caterpillar norms to determine acceptability. To be effective as an indicator, S O S must be performed on a continuing basis. Intermittent sampling will not allow wear rate trend lines to be established.

S O S Sampling Valve (if equipped) Obtain at Every 250 Hour Interval or Oil Change.Obtain S O S samples at regularly scheduled intervals to monitor the condition and maintenance requirements of your engine. Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the engine crankcase.Consult your Caterpillar dealer for complete information and assistance in establishing an S O S program for your engine(s).S O S Analysis

S O S is composed of three basic tests: * Wear Analysis* Chemical and Physical Tests* Oil Condition Analysis Wear analysis is performed with an atomic absorption spectrophotometer to monitor component wear by identifying and measuring concentrations, in parts per million, of wear elements present in the oil. Based on known normal concentration data, maximum limits of wear elements are established. Impending failures can be identified when test results deviate from concentration levels established as acceptable, based on normal wear. Chemical and physical tests detect the presence of water, fuel and glycol (antifreeze) in the oil and determine whether or not their concentrations exceed established maximum limits. Oil condition is evaluated with infrared analysis. This test determines the presence and measures the amount of contaminants such as soot, sulfur products, oxidation, and nitration products in the oil. Infrared analysis can also assist in customizing (reducing, maintaining or extending) oil change intervals for particular conditions and applications.Infrared analysis should always be accompanied by wear element analysis and chemical and physical tests to assure accurate diagnosis. Infrared analysis must be used to determine oil change intervals. S O S must include Infrared (IR) in the analysis.The test results of the oil samples will then be used as a basis for determining the oil change interval for your engine, giving you the ultimate time between oil changes without the risk of engine damage.Refer to Caterpillar pamphlet Scheduled Oil Sampling, form PEDP7105 for imformation and benefits of S O S.

S O S Sampling Valve (if equipped) Obtain at Every 250 Hour Interval or Oil Change.Obtain S O S samples at regularly scheduled intervals to monitor the condition and maintenance requirements of your engine. Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the engine crankcase.Consult your Caterpillar dealer for complete information and assistance in establishing an S O S program for your engine(s).S O S Analysis

S O S is composed of three basic tests: * Wear Analysis* Chemical and Physical Tests* Oil Condition Analysis Wear analysis is performed with an atomic absorption spectrophotometer to monitor component wear by identifying and measuring concentrations, in parts per million, of wear elements present in the oil. Based on known normal concentration data, maximum limits of wear elements are established. Impending failures can be identified when test results deviate from concentration levels established as acceptable, based on normal wear. Chemical and physical tests detect the presence of water, fuel and glycol (antifreeze) in the oil and determine whether or not their concentrations exceed established maximum limits. Oil condition is evaluated with infrared analysis. This test determines the presence and measures the amount of contaminants such as soot, sulfur products, oxidation, and nitration products in the oil. Infrared analysis can also assist in customizing (reducing, maintaining or extending) oil change intervals for particular conditions and applications.Infrared analysis should always be accompanied by wear element analysis and chemical and physical tests to assure accurate diagnosis. Infrared analysis must be used to determine oil change intervals. S O S must include Infrared (IR) in the analysis.The test results of the oil samples will then be used as a basis for determining the oil change interval for your engine, giving you the ultimate time between oil changes without the risk of engine damage.Refer to Caterpillar pamphlet Scheduled Oil Sampling, form PEDP7105 for imformation and benefits of S O S.