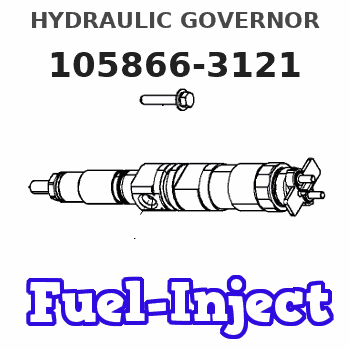

Information hydraulic governor

BOSCH

F 019 Z2E 410

f019z2e410

ZEXEL

105866-3121

1058663121

MITSUBISHI-HEAV

410630500

410630500

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 105866-3121 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1. | [1] | 158502-0420 | BASE |

| 2. | [1] | 029811-8000 | BEARING PLATE |

| 3. | [1] | 158528-0900 | PACKING RING |

| 7. | [1] | 158131-0100 | GEAR SHAFT |

| 10. | [1] | 158028-0000 | O-RING |

| 11. | [1] | 158507-1920 | DIAPHRAGM HOUSING |

| 13. | [1] | 158621-0500 | SLEEVE |

| 18. | [1] | 158699-0921 | COMPENSATOR ASSY |

| 18/1. | [1] | 158610-1101 | POWER PISTON |

| 18/3. | [1] | 158654-0800 | COILED SPRING |

| 18/4. | [1] | 158614-0700 | STOP PIN |

| 18/5. | [1] | 158612-0500 | PLAIN WASHER |

| 18/6. | [1] | 158654-0900 | COILED SPRING |

| 18/7. | [1] | 016110-1220 | LOCKING WASHER |

| 18/8. | [1] | 158612-0401 | BUSHING |

| 18/9. | [2] | 016550-2310 | O-RING |

| 18/10. | [1] | 158615-0800 | PUMP PLUNGER |

| 18/11. | [1] | 025620-1410 | SPRING PIN |

| 35. | [3] | 029330-6070 | GASKET |

| 36. | [3] | 010206-2520 | HEX-SOCKET-HEAD CAP SCREW |

| 50. | [1] | 158600-1020 | FLYWEIGHT ASSEMBLY |

| 51. | [1] | 158106-0100 | PLAIN WASHER |

| 52. | [1] | 029811-0000 | BEARING PLATE |

| 53. | [1] | 158620-1120 | PILOT VALVE |

| 60. | [1] | 158720-0000 | GUIDE LEVER |

| 61. | [2] | 158736-0200 | BEARING PIN |

| 62. | [4] | 025520-1510 | SPLIT PIN |

| 70. | [1] | 158730-0720 | TERMINAL ARM |

| 70/1. | [1] | 158230-0020 | TERMINAL ARM |

| 70/2. | [1] | 158815-0400 | TERMINAL SHAFT |

| 70/3. | [1] | 158815-0000 | TERMINAL SHAFT |

| 70/4. | [2] | 158736-0100 | TAPER PIN |

| 70/5. | [2] | 011006-0620 | SET OF NUTS |

| 70/6. | [1] | 158214-0020 | SPEED DROOP ADJUSTER |

| 70/7. | [1] | 014020-5120 | PLAIN WASHER |

| 70/8. | [1] | 029320-5030 | TAB WASHER |

| 70/9. | [1] | 010535-1220 | FLAT-HEAD SCREW |

| 85. | [1] | 158814-1900 | SPEED CONTROL SHAFT |

| 86. | [2] | 158823-0300 | BUSHING |

| 88. | [1] | 158710-0400 | STRAP |

| 89. | [1] | 029404-5010 | BEARING PIN |

| 95. | [1] | 158211-0100 | STRAP |

| 96. | [2] | 158653-0100 | WIRE |

| 104. | [1] | 158017-0900 | GASKET |

| 105. | [1] | 158962-5700 | COVER |

| 106. | [4] | 029010-6350 | BLEEDER SCREW M6P1.0L22 |

| 108. | [1] | 158567-0800 | SET OF NUTS |

| 109. | [1] | 029240-6020 | UNION NUT |

| 110. | [1] | 158567-0800 | SET OF NUTS |

| 111. | [1] | 029240-6020 | UNION NUT |

| 112. | [2] | 026512-1640 | GASKET D15.9&12.2T1 |

| 113. | [1] | 378050-6120 | AIR FILTER |

| 116. | [1] | 158567-0400 | BLEEDER SCREW |

| 117. | [1] | 158565-0000 | UNION NUT |

| 118. | [1] | 158527-0200 | NEEDLE VALVE |

| 119. | [1] | 016500-0710 | O-RING |

| 120. | [1] | 158901-8200 | ADAPTOR |

| 123. | [2] | 026512-1640 | GASKET D15.9&12.2T1 |

| 124. | [2] | 029111-2070 | CAPSULE M12P1.5L10 |

| 130. | [1] | 029331-8040 | GASKET |

| 131. | [1] | 158660-0320 | CONTROL VALVE |

| 135. | [1] | 158515-0900 | INDICATOR PLATE |

| 137. | [1] | 158515-1000 | INDICATOR PLATE |

| 140. | [1] | 158820-0820 | POINTER |

| 142. | [1] | 158820-0820 | POINTER |

| 163. | [1] | 010210-1420 | HEX-SOCKET-HEAD CAP SCREW |

| 164. | [1] | 026510-1340 | GASKET D13.4&10.2T1 |

| 190. | [1] | 158017-1000 | GASKET |

| 200. | [1] | 158599-7220 | SPARE PART |

Include in #2:

105866-3121

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

105866-3121

410630500 MITSUBISHI-HEAV

HYDRAULIC GOVERNOR

K 35CA HYDRAULIC GOVERNOR Hydraulic RHD10 Others

K 35CA HYDRAULIC GOVERNOR Hydraulic RHD10 Others

Information:

Fluid Penetration

Always use a board or cardboard when checking for a leak. Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing serious injury, and possible death.If fluid is injected into your skin, it must be treated by a doctor familiar with this type of injury immediately.Asbestos Information

Caution should be used to avoid breathing dust that may be generated when handling components containing asbestos fibers. If this dust is inhaled, it can be hazardous to your health.Components in Caterpillar products that may contain asbestos fibers are brake pads, brake band and lining assemblies, clutch plates and some gaskets.The asbestos used in these components is usually bound in a resin or sealed in some way. Normal handling is not hazardous as long as airborne dust which contains asbestos is not generated.If dust which may contain asbestos is present, there are several common sense guidelines that should be followed.* Never use compressed air for cleaning.* Avoid brushing or grinding of asbestos containing materials.* For clean up, use wet methods or a vacuum equipped with a high efficiency particulate air (HEPA) filter.* Use exhaust ventilation on permanent machining jobs.* Wear an approved respirator if there is no other way to control the dust.* Comply with applicable rules and regulations for the work place (for example in the U.S.A., OSHA requirements as set forth in 29 CFR 1910.1001).* Follow environmental rules and regulations for disposal of asbestos.* Avoid areas where asbestos particles may be in the air.Lines, Tubes and Hoses

Do not bend or strike high pressure lines. Do not install bent or damaged lines, tubes or hoses.Repair any loose or damaged fuel and oil lines, tubes and hoses. Leaks can cause fires.Inspect all lines, tubes and hoses carefully. Do not use your bare hands to check for leaks. Tighten all connections to the recommend torque.* End fittings damaged or leaking.* Outer covering chafed or cut and wire reinforcing exposed.* Outer covering ballooning locally.* Evidence of kinking or crushing of the flexible part of the hose.* Armoring embedded in the outer cover.* End fittings displaced.Burn Prevention

Do not touch any part of an operating engine. Allow the engine to cool before any repairs are performed on the engine.Relieve all pressure in air, oil, fuel or cooling systems before any lines, fittings or related items are disconnected or removed.Coolant

To prevent personal injury, do not step up on engine to remove the filler cap, if applicable. Use an adequate ladder.At operating temperature, the engine coolant is hot and under pressure. The radiator and all lines to heaters or the engine contain hot water. When pressure is relieved rapidly, this hot water can turn into steam.Any contact with hot water or steam can cause severe burns.Check the coolant level only after the engine has been stoped and the filler cap is cool enough to remove with your bare hand.Remove the cooling system filler cap slowly to relieve pressure.Supplemental cooling system additive contains alkali. To prevent personal injury, avoid contact with the skin and

Always use a board or cardboard when checking for a leak. Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing serious injury, and possible death.If fluid is injected into your skin, it must be treated by a doctor familiar with this type of injury immediately.Asbestos Information

Caution should be used to avoid breathing dust that may be generated when handling components containing asbestos fibers. If this dust is inhaled, it can be hazardous to your health.Components in Caterpillar products that may contain asbestos fibers are brake pads, brake band and lining assemblies, clutch plates and some gaskets.The asbestos used in these components is usually bound in a resin or sealed in some way. Normal handling is not hazardous as long as airborne dust which contains asbestos is not generated.If dust which may contain asbestos is present, there are several common sense guidelines that should be followed.* Never use compressed air for cleaning.* Avoid brushing or grinding of asbestos containing materials.* For clean up, use wet methods or a vacuum equipped with a high efficiency particulate air (HEPA) filter.* Use exhaust ventilation on permanent machining jobs.* Wear an approved respirator if there is no other way to control the dust.* Comply with applicable rules and regulations for the work place (for example in the U.S.A., OSHA requirements as set forth in 29 CFR 1910.1001).* Follow environmental rules and regulations for disposal of asbestos.* Avoid areas where asbestos particles may be in the air.Lines, Tubes and Hoses

Do not bend or strike high pressure lines. Do not install bent or damaged lines, tubes or hoses.Repair any loose or damaged fuel and oil lines, tubes and hoses. Leaks can cause fires.Inspect all lines, tubes and hoses carefully. Do not use your bare hands to check for leaks. Tighten all connections to the recommend torque.* End fittings damaged or leaking.* Outer covering chafed or cut and wire reinforcing exposed.* Outer covering ballooning locally.* Evidence of kinking or crushing of the flexible part of the hose.* Armoring embedded in the outer cover.* End fittings displaced.Burn Prevention

Do not touch any part of an operating engine. Allow the engine to cool before any repairs are performed on the engine.Relieve all pressure in air, oil, fuel or cooling systems before any lines, fittings or related items are disconnected or removed.Coolant

To prevent personal injury, do not step up on engine to remove the filler cap, if applicable. Use an adequate ladder.At operating temperature, the engine coolant is hot and under pressure. The radiator and all lines to heaters or the engine contain hot water. When pressure is relieved rapidly, this hot water can turn into steam.Any contact with hot water or steam can cause severe burns.Check the coolant level only after the engine has been stoped and the filler cap is cool enough to remove with your bare hand.Remove the cooling system filler cap slowly to relieve pressure.Supplemental cooling system additive contains alkali. To prevent personal injury, avoid contact with the skin and