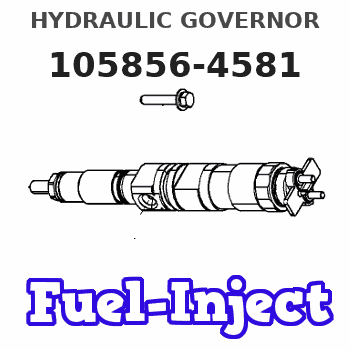

Information hydraulic governor

BOSCH

F 019 Z1F 174

f019z1f174

ZEXEL

105856-4581

1058564581

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 105856-4581 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1. | [1] | 158502-0420 | BASE |

| 2. | [1] | 029811-8000 | BEARING PLATE |

| 3. | [1] | 158528-0900 | PACKING RING |

| 7. | [1] | 158131-0100 | GEAR SHAFT |

| 10. | [1] | 158028-0000 | O-RING |

| 11. | [1] | 158507-1120 | DIAPHRAGM HOUSING |

| 13. | [1] | 158621-0500 | SLEEVE |

| 18. | [1] | 158699-0521 | COMPENSATOR ASSY |

| 18/1. | [1] | 158610-0901 | POWER PISTON |

| 18/3. | [1] | 158654-1000 | COILED SPRING |

| 18/4. | [1] | 158614-0300 | STOP PIN |

| 18/5. | [1] | 158612-0500 | PLAIN WASHER |

| 18/6. | [1] | 158654-1100 | COILED SPRING |

| 18/7. | [1] | 016110-1220 | LOCKING WASHER |

| 18/8. | [1] | 158612-0001 | BUSHING |

| 18/9. | [2] | 158528-1300 | O-RING |

| 18/10. | [1] | 158615-0400 | PUMP PLUNGER |

| 18/11. | [1] | 025620-1410 | SPRING PIN |

| 35. | [3] | 029330-6070 | GASKET |

| 36. | [3] | 010206-2520 | HEX-SOCKET-HEAD CAP SCREW |

| 50. | [1] | 158600-1020 | FLYWEIGHT ASSEMBLY |

| 51. | [1] | 158106-0100 | PLAIN WASHER |

| 52. | [1] | 029811-0000 | BEARING PLATE |

| 53. | [1] | 158620-1220 | PILOT VALVE |

| 60. | [2] | 158220-0000 | GUIDE LEVER |

| 61. | [2] | 158736-0200 | BEARING PIN |

| 62. | [4] | 025520-1510 | SPLIT PIN |

| 70. | [1] | 158730-0220 | TERMINAL ARM |

| 70/1. | [1] | 158230-0020 | TERMINAL ARM |

| 70/2. | [1] | 158315-0200 | TERMINAL SHAFT |

| 70/3. | [1] | 158315-0200 | TERMINAL SHAFT |

| 70/4. | [2] | 158736-0100 | TAPER PIN |

| 70/5. | [2] | 011006-0620 | SET OF NUTS |

| 70/6. | [1] | 158214-0020 | SPEED DROOP ADJUSTER |

| 70/7. | [1] | 014020-5120 | PLAIN WASHER |

| 70/8. | [1] | 029320-5030 | TAB WASHER |

| 70/9. | [1] | 010535-1220 | FLAT-HEAD SCREW |

| 85. | [1] | 158814-0900 | SPEED CONTROL SHAFT |

| 86. | [2] | 158823-0300 | BUSHING |

| 86. | [2] | 158823-0300 | BUSHING |

| 87. | [1] | 158322-0200 | COILED SPRING |

| 88. | [1] | 158710-0400 | STRAP |

| 89. | [1] | 029404-5010 | BEARING PIN |

| 95. | [1] | 158211-0100 | STRAP |

| 96. | [2] | 158653-0100 | WIRE |

| 104. | [1] | 158017-0900 | GASKET |

| 105. | [1] | 158964-3420 | PNEUMATIC CONTROLLER |

| 105/1. | [1] | 158562-4600 | COVER |

| 105/2. | [1] | 158910-0200 | CYLINDER |

| 105/3. | [3] | 029050-6090 | FLAT-HEAD SCREW |

| 105/4. | [1] | 014110-6440 | LOCKING WASHER |

| 105/5. | [1] | 158416-0000 | FLAT-HEAD SCREW |

| 105/6. | [1] | 158915-0700 | UNION NUT |

| 105/7. | [1] | 158918-0000 | PLAIN WASHER D30&10.8T1.00 |

| 105/8/1. | [1] | 158412-0100 | COILED SPRING K1.0 |

| 105/8/1. | [1] | 158412-0200 | COILED SPRING K2.0 |

| 105/8/1. | [1] | 158412-0300 | COILED SPRING K3.0 |

| 105/8/1. | [1] | 158412-0400 | COILED SPRING K4.0 |

| 105/8/1. | [1] | 158412-0500 | COILED SPRING K5.0 |

| 105/8/1. | [1] | 158912-1800 | COILED SPRING K3.4 |

| 105/8/1. | [1] | 158912-1900 | COILED SPRING K2.5 |

| 105/8/1. | [1] | 158912-3300 | COILED SPRING K4.5 |

| 105/9/1. | [1] | 158412-0000 | COILED SPRING K7.0 |

| 105/9/1. | [1] | 158912-0500 | COILED SPRING K4.9 |

| 105/9/1. | [1] | 158912-0600 | COILED SPRING K5.1 |

| 105/9/1. | [1] | 158912-0700 | COILED SPRING K5.2 |

| 105/9/1. | [1] | 158912-1100 | COILED SPRING K4.8 |

| 105/9/1. | [1] | 158912-1200 | COILED SPRING K5.4 |

| 105/9/1. | [1] | 158912-2300 | COILED SPRING K6.8 |

| 105/9/1. | [1] | 158912-2400 | COILED SPRING K7.0 |

| 105/9/1. | [1] | 158912-2500 | COILED SPRING K7.3 |

| 105/9/1. | [1] | 158912-2600 | COILED SPRING K7.4 |

| 105/10. | [1] | 158918-0000 | PLAIN WASHER D30&10.8T1.00 |

| 105/11. | [1] | 158413-0001 | STOP PIN |

| 105/12. | [1] | 158414-0000 | PUMP PLUNGER |

| 105/13. | [1] | 158414-0100 | DIAPHRAGM |

| 105/14. | [1] | 158414-0200 | PLATE |

| 105/15. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 105/16. | [1] | 158910-0300 | CAP |

| 105/17. | [1] | 158915-1000 | FLAT-HEAD SCREW |

| 105/18. | [1] | 029630-9050 | O-RING |

| 105/19. | [1] | 158567-1500 | WING NUT |

| 105/21. | [1] | 158904-2020 | ROUND NUT |

| 105/22. | [1] | 158916-0000 | SET OF NUTS |

| 105/23. | [2] | 029050-6220 | FLAT-HEAD SCREW |

| 105/24. | [2] | 029320-6010 | LOCKING WASHER |

| 105/25. | [2] | 158909-0200 | BLEEDER SCREW |

| 105/26. | [1] | 027114-1040 | INLET UNION |

| 105/27. | [2] | 029331-4120 | GASKET D18&14.2T1.5 |

| 105/28. | [1] | 027414-2640 | EYE BOLT |

| 105/30. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 105/31. | [1] | 158567-1200 | SET OF NUTS |

| 105/35. | [1] | 026512-1640 | GASKET D15.9&12.2T1 |

| 105/36. | [1] | 158066-0000 | BLEEDER SCREW |

| 106. | [4] | 029010-6350 | BLEEDER SCREW M6P1.0L22 |

| 118. | [1] | 158527-0200 | NEEDLE VALVE |

| 119. | [1] | 016500-0710 | O-RING |

| 123. | [2] | 026512-1640 | GASKET D15.9&12.2T1 |

| 123. | [2] | 026512-1640 | GASKET D15.9&12.2T1 |

| 124. | [2] | 029111-2070 | CAPSULE M12P1.5L10 |

| 124. | [2] | 029111-2070 | CAPSULE M12P1.5L10 |

| 130. | [1] | 029331-8040 | GASKET |

| 131. | [1] | 158660-0320 | CONTROL VALVE |

| 135. | [1] | 158515-0700 | INDICATOR PLATE |

| 137. | [1] | 158515-0800 | INDICATOR PLATE |

| 140. | [1] | 158820-0620 | POINTER |

| 142. | [1] | 158820-0620 | POINTER |

| 158. | [1] | 015040-0880 | BEARING PIN |

| 163. | [1] | 010210-1420 | HEX-SOCKET-HEAD CAP SCREW |

| 164. | [1] | 026510-1340 | GASKET D13.4&10.2T1 |

| 190. | [1] | 158017-1000 | GASKET |

| 200. | [1] | 158599-6920 | SPARE PART |

Include in #2:

105856-4581

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

(Engine Crankshaft Turns Freely) (Exhaust Smoke Can Be Seen While Starting)

Recommended Procedure

1. Cold Outside Temperatures ... It may be necessary to use starting aids, or to heat engine oil or coolant at temperatures below 10°C (50°F).2. Air in Fuel System ... With air in the fuel system the engine will normally be difficult to start, run rough and release a large amount of white smoke. To remove the air from the fuel system, open the manual bleed valve on the fuel injection pump housing. Operate the priming pump until the flow of fuel from the manual bleed valve is free of air. Close the manual bleed valve and fasten the fuel priming pump. Start the engine. If the engine still does not run smooth or releases a large amount of white smoke, loosen the fuel line nuts one at a time at the cylinder heads, and permit the fuel to come out until it is free of air. Tighten the fuel line nuts. If air is not removed in this way, put 35 kPa (5 psi) of air pressure to the fuel tank.

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check for leakage at the connections between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.3. Low Quality Fuel ... Remove a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, remove fuel from the tank until it is free of water and fill with a good quality fuel. Change the fuel filter and "prime" (remove the air and/or low quality fuel from the fuel system) the fuel system with the fuel priming pump. If there is no water in the fuel, prime and start the engine by using an outside source of fuel. If engine starts correctly using different fuel, remove all fuel from the tank and fill with good quality fuel. Prime the fuel system if necessary.4. Low Fuel Pressure ... Change the fuel filter. If the pressure is still low, check the bypass valve in the fuel transfer pump. Debris in the system can make the valve become stationary in the open position.5. Fuel Injection Timing Not Correct ... Check and make necessary adjustments as per Testing and Adjusting section of this Service Manual.6. Valve Adjustment Not Correct ... Check and make necessary adjustments as per Testing and Adjusting section of this Service Manual. Intake valve clearance is 0.38 mm (.015 in) and exhaust valve clearance is 0.64 mm (.025 in).7. Bad Fuel Nozzle(s) ... Remove and test the fuel nozzles.8. Low Compression ... See Misfiring and Running Rough.Exhaust Smoke

Recommended Procedure

1. Cold Outside Temperatures ... It may be necessary to use starting aids, or to heat engine oil or coolant at temperatures below 10°C (50°F).2. Air in Fuel System ... With air in the fuel system the engine will normally be difficult to start, run rough and release a large amount of white smoke. To remove the air from the fuel system, open the manual bleed valve on the fuel injection pump housing. Operate the priming pump until the flow of fuel from the manual bleed valve is free of air. Close the manual bleed valve and fasten the fuel priming pump. Start the engine. If the engine still does not run smooth or releases a large amount of white smoke, loosen the fuel line nuts one at a time at the cylinder heads, and permit the fuel to come out until it is free of air. Tighten the fuel line nuts. If air is not removed in this way, put 35 kPa (5 psi) of air pressure to the fuel tank.

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check for leakage at the connections between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.3. Low Quality Fuel ... Remove a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, remove fuel from the tank until it is free of water and fill with a good quality fuel. Change the fuel filter and "prime" (remove the air and/or low quality fuel from the fuel system) the fuel system with the fuel priming pump. If there is no water in the fuel, prime and start the engine by using an outside source of fuel. If engine starts correctly using different fuel, remove all fuel from the tank and fill with good quality fuel. Prime the fuel system if necessary.4. Low Fuel Pressure ... Change the fuel filter. If the pressure is still low, check the bypass valve in the fuel transfer pump. Debris in the system can make the valve become stationary in the open position.5. Fuel Injection Timing Not Correct ... Check and make necessary adjustments as per Testing and Adjusting section of this Service Manual.6. Valve Adjustment Not Correct ... Check and make necessary adjustments as per Testing and Adjusting section of this Service Manual. Intake valve clearance is 0.38 mm (.015 in) and exhaust valve clearance is 0.64 mm (.025 in).7. Bad Fuel Nozzle(s) ... Remove and test the fuel nozzles.8. Low Compression ... See Misfiring and Running Rough.Exhaust Smoke