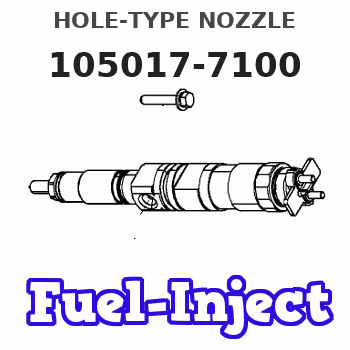

Information hole-type nozzle

BOSCH

0 433 171 699

0433171699

ZEXEL

105017-7100

1050177100

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Injector Overhaul Kit Nozzle 150P1076 0433171699 Valve F00RJ00399,Compatible With RENAULT,Compatible With IVECO 0445120020 0445120019 0445120084

IQBKCPEO Compatible with multiple models, fitting OE numbers 0445120020, 0445120019, 0445120084, 150P1076, 0433171699, F00RJ00399 for precise compatibility. || Compatible with fuel injection technology to optimize fuel efficiency and enhance engine performance. || Compatible with easy installation, requiring no complex tools to save time and effort. || Speeds up injector repair processes. || Improves throttle response and overall engine performance

IQBKCPEO Compatible with multiple models, fitting OE numbers 0445120020, 0445120019, 0445120084, 150P1076, 0433171699, F00RJ00399 for precise compatibility. || Compatible with fuel injection technology to optimize fuel efficiency and enhance engine performance. || Compatible with easy installation, requiring no complex tools to save time and effort. || Speeds up injector repair processes. || Improves throttle response and overall engine performance

Diesel Injector Repair Kits Nozzle DLLA150P1076 (0433171699), High Speed Steel Valve F00RJ00399 For Nissan 0445120084 0445120019 - (Color: F00RJ00399)

Generic Color: F00RJ00399 || Diesel Engine || Brand Name: || Material:

Generic Color: F00RJ00399 || Diesel Engine || Brand Name: || Material:

You can express buy:

USD 35.99

13-05-2025

13-05-2025

0445120020 0445120019 0445120084 Injector repair Kit Nozzle DLLA150P1076 0433171699 Valve F00RJ00399 for RENAULT IVECO

USD 54.5

13-05-2025

13-05-2025

4X DLLA150P1076 0433171699 Diesel Injector Nozzle DLLA 150 P 1076 Pump Spray for Bosch RENAULT 0445120084 0445120019 0445120020

Images:

USD 17.99

[13-May-2025]

USD 130.68

[13-May-2025]

USD 12.99

[13-May-2025]

USD 35.99

[13-May-2025]

Cross reference number

Zexel num

Bosch num

Firm num

Name

105017-7100

0 433 171 699

HOLE-TYPE NOZZLE

* C 55LB NOZZLE

* C 55LB NOZZLE

Information:

Illustration 3 g06519715

DOC brackets

Illustration 4 g06519717

DOC

Connect the welding ground cable directly to the DOC brackets or the DOC that will be welded. Place the ground cable as close as possible to the weld. This location will reduce the possibility of welding current damage bearings, hydraulic components, electrical components, and ground straps.Note: If electrical components are used as a ground for the welder, current flow from the welder could severely damage the component. Current flow from the welder could also severely damage electrical components that are located between the welder ground and the weld.

Illustration 5 g06519270

Weld blanket

Illustration 6 g06519272

Use a weld blanket draped over the engine to protect the engine from weld splatter. Likely need 2 or 3 blankets to cover between DOCs and the entire engine from splatter.

Illustration 7 g06519274

Illustration 8 g06519277

(1) 536-5400 Plate

Clean the top surface in the two locations where plates (1) will be welded in place with either a wire wheel or a flap disk.Note: Failure to clean the weld area could result in poor weld quality.

Illustration 9 g06519323

(D1) 6 2 mm (0.236 0.079 inch)

Illustration 10 g06519297

(D1) 6 2 mm (0.236 0.079 inch)

(D2) 43 3 mm (1.693 0.118 inch)

Illustration 11 g06519348

(D2) 43 3 mm (1.693 0.118 inch)

Set the plates on the top side of the housing and line up perpendicular to the front face. Position the plates to dimension (D1) from the front edge of the top plate.

Position the plates to dimension (D2) from the far edge of the rounded plate. There is a chamfer and fillet weld that will make measurements less precise. Use a tape measure to position.Note: Etching marks may also be present on the top of the unit and can be used for further positional guidance.

Illustration 12 g06519373

(W1) Tack weld

With the plates in place, add tack welds (W1) to the plates shown in Illustration 12. Use 308L weld wire.

Illustration 13 g06519408

(W2) 50 to 100 mm (1.969 to 3.937 inch)

Skip fillet weld (W2) down the side of each plate and then weld at the ends of each plates. Use 308L weld wire.

Illustration 14 g06519430

Finished product

Verify the weld quality and look for the following:

Cracks

Porosity

Inclusions

Convexity/Excess Weld Material

Concavity/Under Fill

Excess Penetration

Lack of Penetration

Fillet Weld - Undersize

Lack of Fusion

Undercut

Toe Radius

Overlap

Poor Restarts/Tie-ins

Cleaning/Grinding

Spatter/Arc Strike/Wire Stub

Illustration 15 g06519435

Mark the new plates with "THIS SIDE UP".Note: Make sure that the text is visible and stands out on the DOC.

Have questions with 105017-7100?

Group cross 105017-7100 ZEXEL

105017-7100

0 433 171 699

HOLE-TYPE NOZZLE