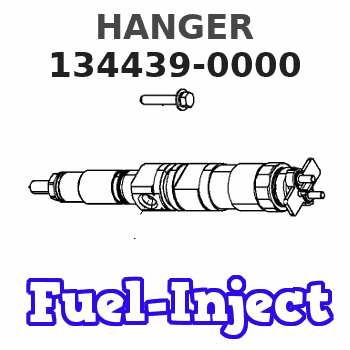

Information hanger

BOSCH

9 411 612 288

9411612288

ZEXEL

134439-0000

1344390000

ISUZU

1156193840

1156193840

Rating:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

134439-0000

9 411 612 288

1156193840 ISUZU

HANGER

C 14GV HANGER Others

C 14GV HANGER Others

134439-0000

9 411 612 288

223436010A HINO

HANGER

C 14GV HANGER Others

C 14GV HANGER Others

134439-0000

9 411 612 288

ME740147 MITSUBISHI

HANGER

C 14GV HANGER Others

C 14GV HANGER Others

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.The actuator and pump groups of these fuel injectors are sensitive to debris in the oil. The injector may malfunction due to debris in the oil, causing seizure, or high leaks in components.

Table 1

Revision Table

Revision Summary of Changes

3 Added serial numbers. Improvement Procedure

Clean oil rail after pump failure.Reference: Refer to Special Instruction, REHS3819 for the procedure to clean the oil rail after engine failure to avoid debris in the oil system.

Use clean oil and clean filters.The life of the injector depends on the oil quality. It can be increased if good cleaning practices are performed before installing the injectors.Reference: Refer to Operation and Maintenance Manual, SEBU6250 and Operation and Maintenance Manual, SEBU6251 for direction on oil sampling intervals and optimizing engine oil life.

Illustration 1 g06207717

(1) Actuator

(2) Pump Group

(3) Valve Seat Damage Due to Debris in the Oil SystemInjector Failure Due To Damage From Debris In The Oil May Not Be A Warrantable Failure

Illustration 2 g06244961

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.The actuator and pump groups of these fuel injectors are sensitive to debris in the oil. The injector may malfunction due to debris in the oil, causing seizure, or high leaks in components.

Table 1

Revision Table

Revision Summary of Changes

3 Added serial numbers. Improvement Procedure

Clean oil rail after pump failure.Reference: Refer to Special Instruction, REHS3819 for the procedure to clean the oil rail after engine failure to avoid debris in the oil system.

Use clean oil and clean filters.The life of the injector depends on the oil quality. It can be increased if good cleaning practices are performed before installing the injectors.Reference: Refer to Operation and Maintenance Manual, SEBU6250 and Operation and Maintenance Manual, SEBU6251 for direction on oil sampling intervals and optimizing engine oil life.

Illustration 1 g06207717

(1) Actuator

(2) Pump Group

(3) Valve Seat Damage Due to Debris in the Oil SystemInjector Failure Due To Damage From Debris In The Oil May Not Be A Warrantable Failure

Illustration 2 g06244961

Have questions with 134439-0000?

Group cross 134439-0000 ZEXEL

Isuzu

134439-0000

9 411 612 288

1156193840

HANGER

Hino

134439-0000

9 411 612 288

223436010A

HANGER

Mitsubishi

134439-0000

9 411 612 288

ME740147

HANGER